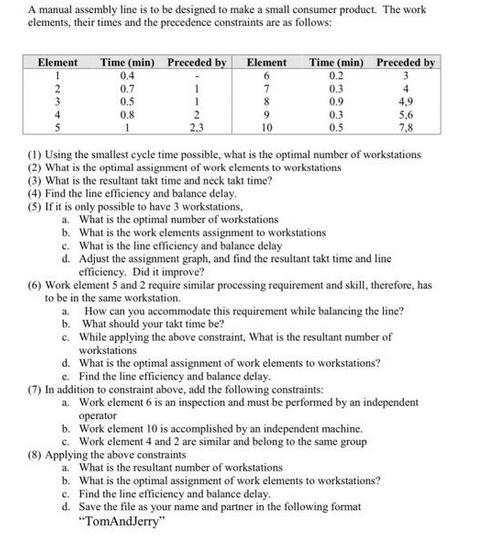

Question: A manual assembly line is to be designed to make a small consumer product. The work elements, their times and the precedence constraints are

A manual assembly line is to be designed to make a small consumer product. The work elements, their times and the precedence constraints are as follows: Element Time (min) Preceded by 1 -NMI5 2 3 4 0.4 0.7 0.5 0.8 1 2,3 Element 8 9 10 (8) Applying the above constraints Time (min) Preceded by 3 4 4,9 5,6 7,8 (1) Using the smallest cycle time possible, what is the optimal number of workstations (2) What is the optimal assignment of work elements to workstations (3) What is the resultant takt time and neck takt time? (4) Find the line efficiency and balance delay. (5) If it is only possible to have 3 workstations, 0.2 0.3 0.9 0.3 0.5 a. What is the optimal number of workstations b. What is the work elements assignment to workstations e. What is the line efficiency and balance delay d. Adjust the assignment graph, and find the resultant takt time and line efficiency. Did it improve? (6) Work element 5 and 2 require similar processing requirement and skill, therefore, has to be in the same workstation. a. How can you accommodate this requirement while balancing the line? b. What should your takt time be? c. While applying the above constraint, What is the resultant number of workstations d. What is the optimal assignment of work elements to workstations? e. Find the line efficiency and balance delay. (7) In addition to constraint above, add the following constraints: a. Work element 6 is an inspection and must be performed by an independent operator b. Work element 10 is accomplished by an independent machine. c. Work element 4 and 2 are similar and belong to the same group a. What is the resultant number of workstations b. What is the optimal assignment of work elements to workstations? c. Find the line efficiency and balance delay. d. Save the file as your name and partner in the following format "TomAndJerry"

Step by Step Solution

There are 3 Steps involved in it

To solve this problem we can use the Assembly Line Balancing ALB algorithm ALB aims to optimize the assignment of work elements to workstations in a p... View full answer

Get step-by-step solutions from verified subject matter experts