Question

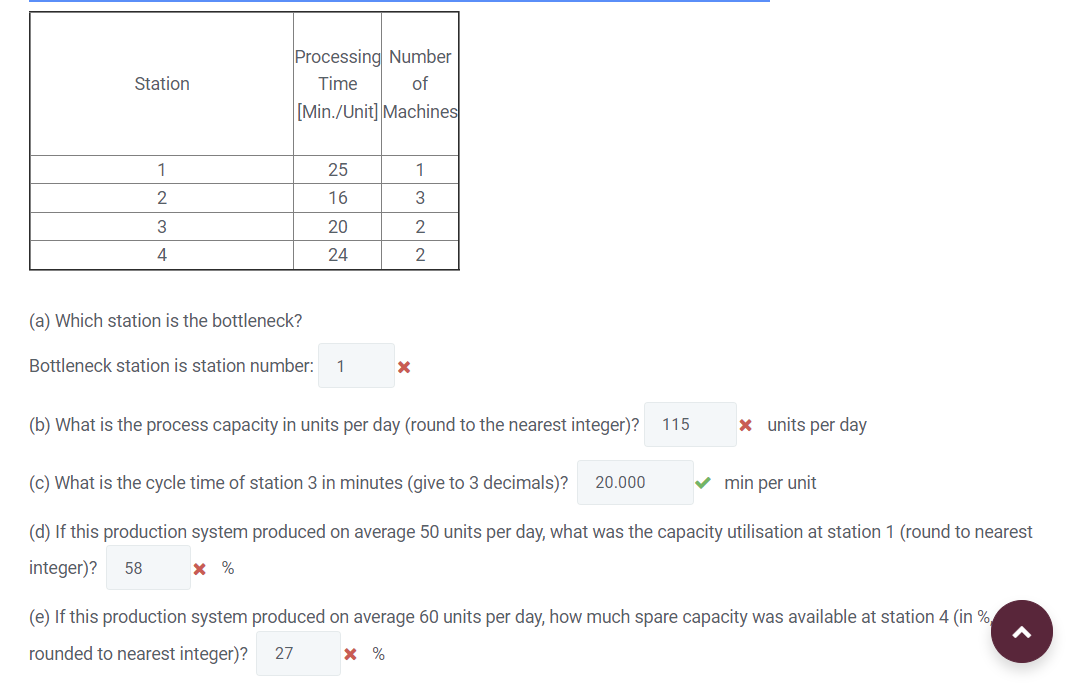

A manufacturing company produces a single product at four workstations in series (assume no variability). The company operates 3 shifts of 8 hrs per day,

A manufacturing company produces a single product at four workstations in series (assume no variability). The company operates 3 shifts of 8 hrs per day, 5 days per week. Each shift contains one lunch break of 40 min. The processing time per unit as well as the number of machines per station is indicated in the table below. After every 500 units produced, the tools used in the machines at station 1 need to be replaced. It takes on average 30 minutes per machine to replace the tools. All the machines can process one unit at a time only, except for station 1 where each machine can process 5 units simultaneously.

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started