Question

A new salt factory is being developed at a remote location in salt affected region of Victoria. This factory does not have access to utilities

A new salt factory is being developed at a remote location in salt affected region of Victoria. This factory does not have access to utilities such as grid electricity, piped gas and town water supply. The factory site has a bore well that can be used to meet the water requirements of the salt factory. The average annual temperature of the bore water is 20C and the average annual ambient temperature is 20C (T0dead state temperature) and the average annual atmospheric pressure is 100.3kPa (P0dead state pressure).

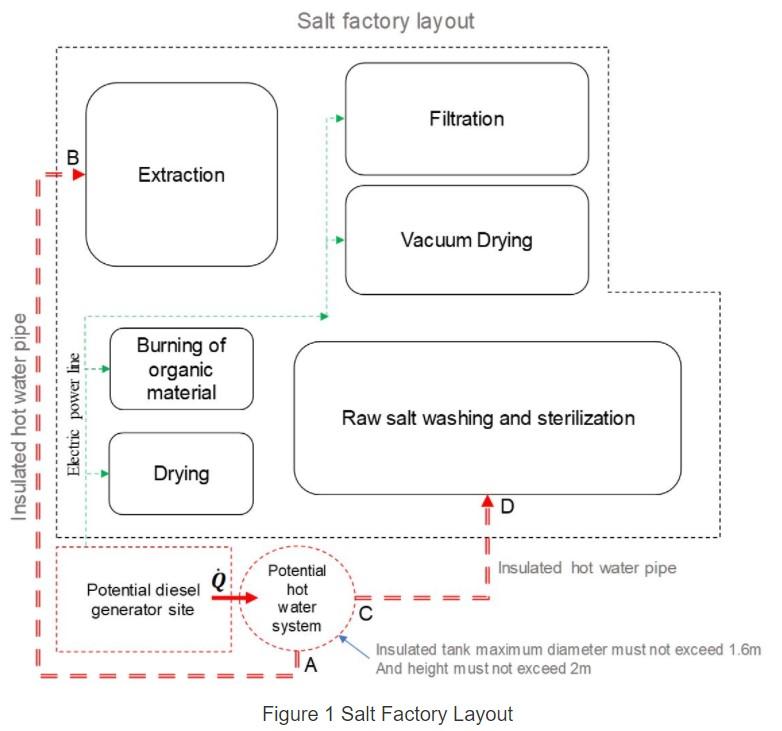

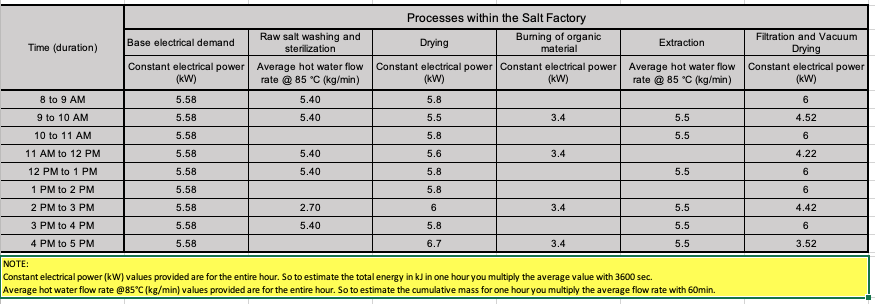

The proprietors of the planned salt factory have hired an engineering consulting company to design the new salt factory facility. And you work as a trainee engineer in this company. Your team leader who is a senior engineer has given you the responsibility to develop preliminary design of stand-alone utilities supply system for this facility to meet their electrical and hot water demand. The salt factory will operate from 8am to 5pm (9 hours) every day for 5 days per week.

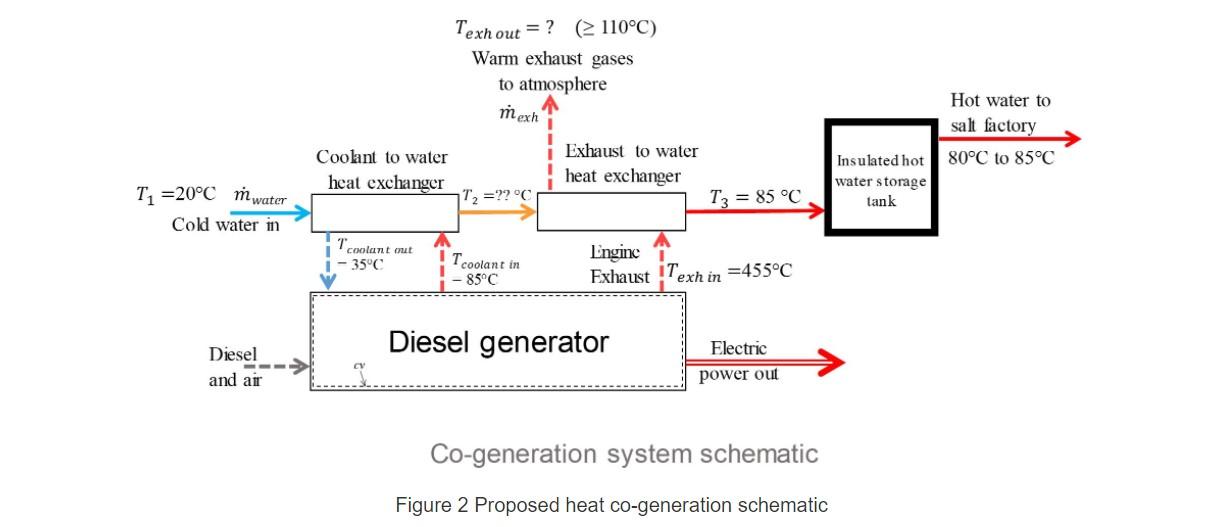

Electrical power is required by number of processes in this salt factory that includes Drying, Burning, Filtration and Vacuum drying along with some base demand for number of other small equipment that need continuous operation. The hot water is required for two main processes that include raw salt washing and sterilization and extraction and the temperature of the hot water must be between 80C to 85C when it reaches this facility. For this reason, it is advised that the water is heated to a maximum temperature of 85C.

During the initial briefing of the project, your team leader has suggested using Diesel generator for electrical energy supply and has asked you to explore the possibility of using waste heat from the Diesel generator to produce hot water. (Note: such systems are commonly known as co-generation system)

Another engineering team that is responsible for design of the salt factory layout and process equipment selection has provided you with the estimated plant utilitiesdemand profile (EXCEL)and the plant layout (shown in figure below).

T =20C mw Cold water in Coolant to water Texh out? (110C) Warm exhaust gases to atmosphere mexh Exhaust to water heat exchanger heat exchanger water T =?? C T3=85 C T coolant out 35C Engine T coolant in - 85C Diesel and air Exhaust Texh in =455C Diesel generator Electric power out Co-generation system schematic Figure 2 Proposed heat co-generation schematic Hot water to sal factory Insulated hot 80C to 85C water storage tank

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started