Answered step by step

Verified Expert Solution

Question

1 Approved Answer

ABC/ABM If you were interested in determining if the setup activity was being performed efficiently and effectively, what additional steps would you perform? Why? 9.

ABC/ABM

If you were interested in determining if the setup activity was being performed efficiently and effectively, what additional steps would you perform? Why?

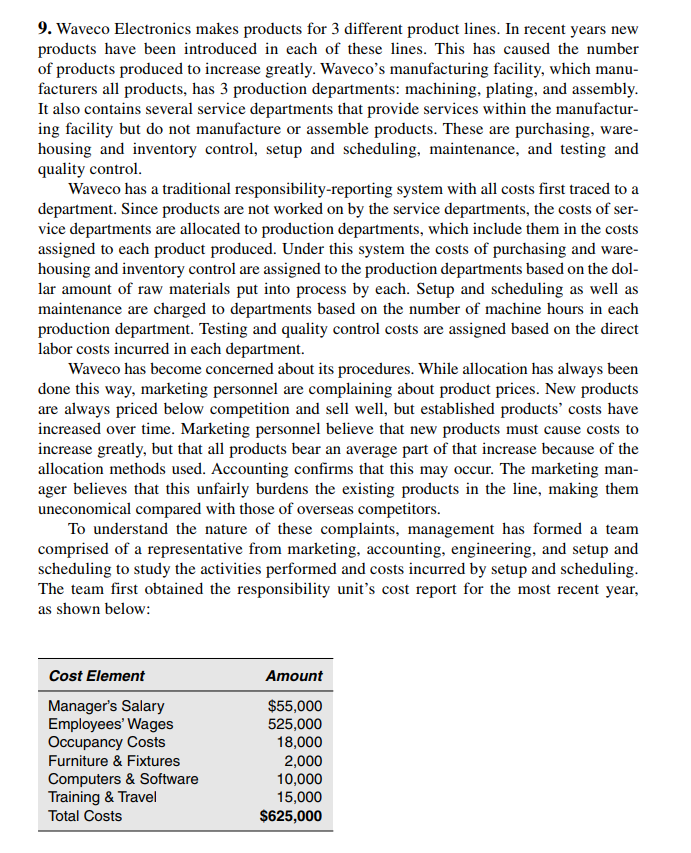

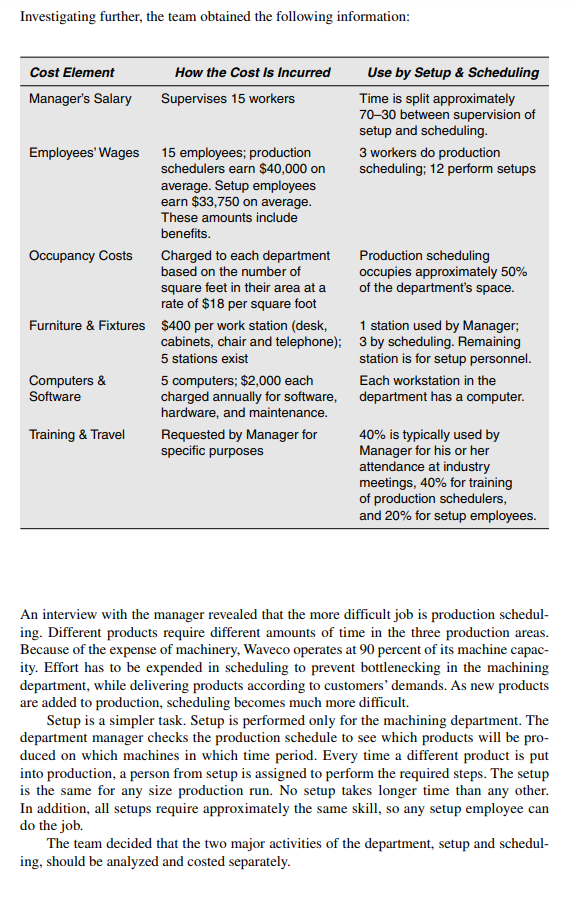

9. Waveco Electronics makes products for 3 different product lines. In recent years new products have been introduced in each of these lines. This has caused the number of products produced to increase greatly. Waveco's manufacturing facility, which manu- facturers all products, has 3 production departments: machining, plating, and assembly It also contains several service departments that provide services within the manufactur- ing facility but do not manufacture or assemble products. These are purchasing, ware housing and inventory control, setup and scheduling, maintenance, and testing and quality control Waveco has a traditional responsibility-reporting system with all costs first traced to a department. Since products are not worked on by the service departments, the costs of ser- vice departments are allocated to production departments, which include them in the costs assigned to each product produced. Under this system the costs of purchasing and ware- housing and inventory control are assigned to the production departments based on the dol- lar amount of raw materials put into process by each. Setup and scheduling as well as maintenance are charged to departments based on the number of machine hours in each production department. Testing and quality control costs are assigned based on the direct labor costs incurred in each department. Waveco has become concerned about its procedures. While allocation has always been done this way, marketing personnel are complaining about product prices. New products are always priced below competition and sell well, but established products' costs have increased over time. Marketing personnel believe that new products must cause costs to increase greatly, but that all products bear an average part of that increase because of the allocation methods used. Accounting confirms that this may occur. The marketing man ager believes that this unfairly burdens the existing products in the line, making them uneconomical compared with those of overseas competitors. To understand the nature of these complaints, management has formed a team comprised of a representative from marketing, accounting, engineering, and setup and scheduling to study the activities performed and costs incurred by setup and scheduling The team first obtained the responsibility unit's cost report for the most recent year as shown below: Cost Element Amount Manager's Salary Employees' Wages Occupancy Costs Furniture & Fixtures Computers & Software Training & Travel Total Costs $55,000 525,000 18,000 2,000 10,000 15,000 $625,000 Investigating further, the team obtained the following information How the Cost Is Incurred Use by Setup & Scheduling Time is split approximately Cost Element Manager's Salary Supervises 15 workers between supervision of setup and scheduling 3 workers do production scheduling; 12 perform setups Employees' Wages15 employees; production schedulers earn $40,000 on average. Setup employees earn $33,750 on average These amounts include benefits Occupancy Costs Charged to each department based on the number of square feet in their area at a rate of $18 per square foot Production scheduling occupies approximately 50% of the department's space Furniture & Fixtures $400 per work station (desk, station used by Manager; 3 by scheduling. Remaining station is for setup personnel. Each workstation in the department has a computer cabinets, chair and telephone); 5 stations exist Computers & Software 5 computers; $2,000 each charged annually for software, hardware, and maintenance Training & Travel Requested by Manager for specific purposes 40% is typically used by Manager for his or her attendance at industry meetings, 40% for training of production schedulers and 20% for setup employees. An interview with the manager revealed that the more difficult job is production schedul ing. Different products require different amounts of time in the three production areas. Because of the expense ity. Effort has to be expended in scheduling to prevent bottlenecking in the machining department, while delivering products according to customers' demands. As new products are added to production, scheduling becomes much more difficult. of machinery, Waveco operates at 90 percent of its machine capac Setup is a simpler task. Setup is performed only for the machining department. The department manager checks the production schedule to see which products will be pro- duced on which machines in which time period. Every time a different product is put into production, a person from setup is assigned to perform the required steps. The setup is the same for any size production run. No setup takes longer time than any other In addition, all setups require approximately the same skill, so any setup employee can do the job. The team decided that the two major activities of the department, setup and schedul ing, should be analyzed and costed separatelyStep by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started