Question

Acme Axles, a tier two supplier to the automotive industry, produces axles using a three-step process that involves rolling steel to a specific diameter, cutting

Acme Axles, a tier two supplier to the automotive industry, produces axles using a three-step process that involves rolling steel to a specific diameter, cutting the steel in eight-foot segments, and then finishing each of the two ends of the axle. Its facility has the capacity to roll 16,000 linear feet of steel each week. Each cut takes one minute, and the cutting saw is operated eight hours a day, five days aweek. It takes 12 minutes for one person to finish a single end, and there are 19 employees (each of whom works 40 hours a week) who perform the finishing task.

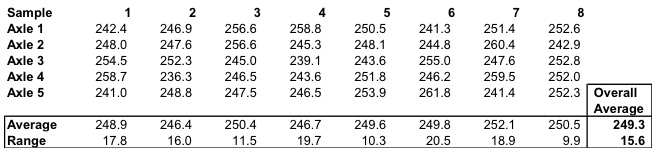

Upper Control LimitX-bar chart: 258.3

Lower Control LimitX-bar chart: 240.3

The diameter of the axle is of critical importance to Acme's customers. Acme uses statistical process control to make sure its rolling equipment is operating properly, measuring the diameter (in mm) of five axles each hour. To create control limits, Acme used the eight samples listed below:

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started