Question: A)Layout strategies B) process layout construct a from to matrix, determine the space requirements, develop an initial schematic diagram, determine the cost of this layout,

A)Layout strategies

B) process layout construct a from to matrix, determine the space requirements, develop an initial schematic diagram, determine the cost of this layout, try to improve the layout, prepare a detailed plan

C) identification of families of products, a high level of training, flexibility and empowerment of employees, being self contained with its own equipment and resources

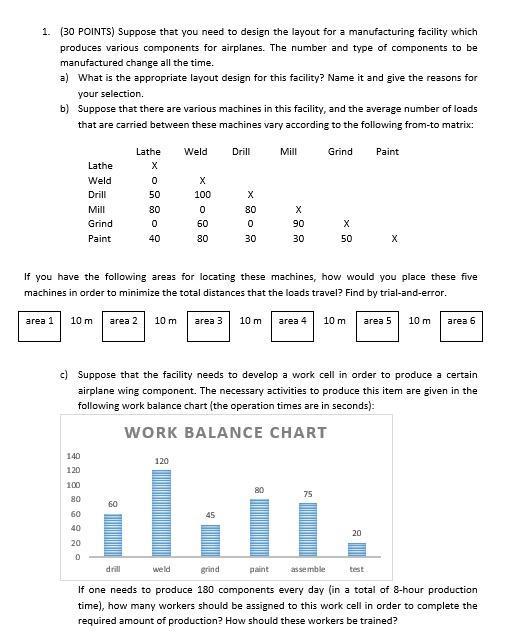

1. (30 POINTS) Suppose that you need to design the layout for a manufacturing facility which produces various components for airplanes. The number and type of components to be manufactured change all the time. a) What is the appropriate layout design for this facility? Name it and give the reasons for your selection. b) Suppose that there are various machines in this facility, and the average number of loads that are carried between these machines vary according to the following from-to matrix: area 1 140 120 100 80 Lathe Weld Drill 60 40 Mill Grind Paint 20 0 Lathe Weld X 0 60 og go drill 50 80 40 X 100 If you have the following areas for locating these machines, how would you place these five machines in order to minimize the total distances that the loads travel? Find by trial-and-error. 10 m area 2 10 m 120 0 60 80 weld Drill area 3 X 80 0 30 10 m Mill X 90 30 c) Suppose that the facility needs to develop a work cell in order to produce a certain airplane wing component. The necessary activities to produce this item are given in the following work balance chart (the operation times are in seconds): WORK BALANCE CHART 80 area 4 Grind X 50 75 Paint 10 m area 5 20 test 10 m area 6 grind paint assemble If one needs to produce 180 components every day (in a total of 8-hour production time), how many workers should be assigned to this work cell in order to complete the required amount of production? How should these workers be trained?

Step by Step Solution

3.44 Rating (176 Votes )

There are 3 Steps involved in it

A The appropriate layout design for this facility is a product layout Some key reasons for selecting ... View full answer

Get step-by-step solutions from verified subject matter experts