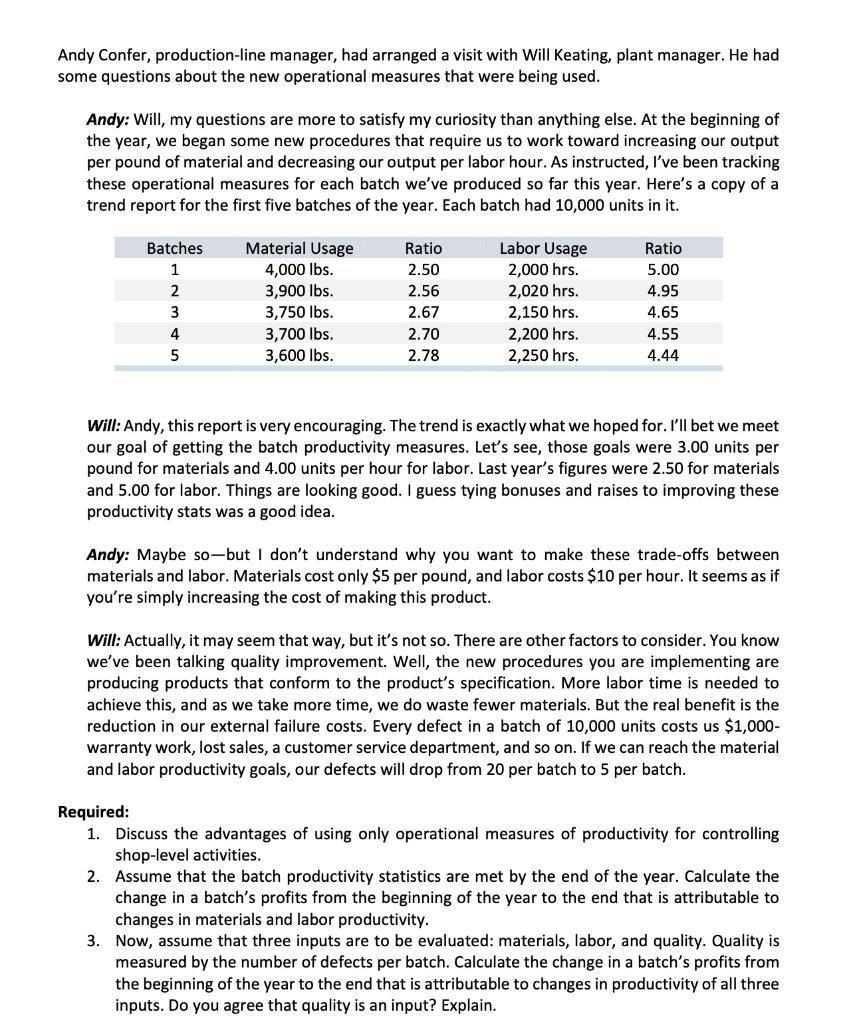

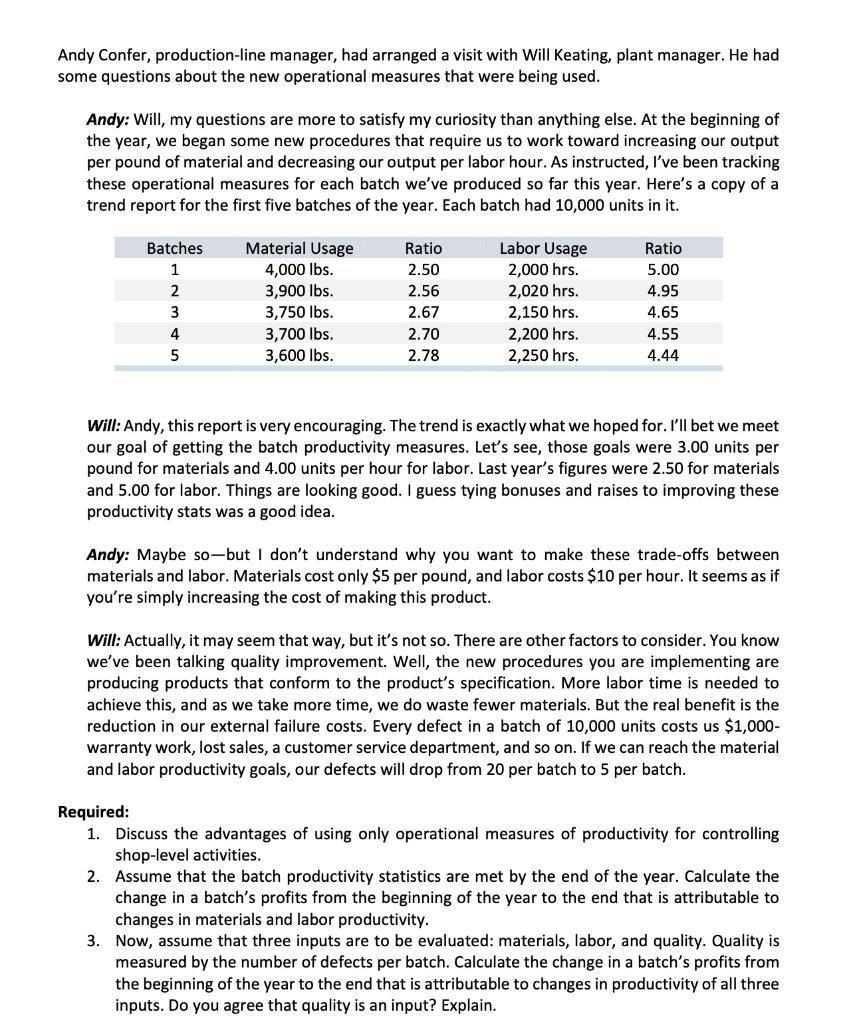

Andy Confer, production-line manager, had arranged a visit with Will Keating, plant manager. He had some questions about the new operational measures that were being used. Andy: Will, my questions are more to satisfy my curiosity than anything else. At the beginning of the year, we began some new procedures that require us to work toward increasing our output per pound of material and decreasing our output per labor hour. As instructed, I've been tracking these operational measures for each batch we've produced so far this year. Here's a copy of a trend report for the first five batches of the year. Each batch had 10,000 units in it. Batches 1 2 3 Material Usage 4,000 lbs. 3,900 lbs. 3,750 lbs. 3,700 lbs. 3,600 lbs. Ratio 2.50 2.56 2.67 2.70 2.78 Labor Usage 2,000 hrs. 2,020 hrs. 2,150 hrs. 2,200 hrs. 2,250 hrs. Ratio 5.00 4.95 4.65 4.55 4.44 4 5 Will: Andy, this report is very encouraging. The trend is exactly what we hoped for. I'll bet we meet our goal of getting the batch productivity measures. Let's see, those goals were 3.00 units per pound for materials and 4.00 units per hour for labor. Last year's figures were 2.50 for materials and 5.00 for labor. Things are looking good. I guess tying bonuses and raises to improving these productivity stats was a good idea. Andy: Maybe so-but I don't understand why you want to make these trade-offs between materials and labor. Materials cost only $5 per pound, and labor costs $10 per hour. It seems as if you're simply increasing the cost of making this product. Will: Actually, it may seem that way, but it's not so. There are other factors to consider. You know we've been talking quality improvement. Well, the new procedures you are implementing are producing products that conform to the product's specification. More labor time is needed to achieve this, and as we take more time, we do waste fewer materials. But the real benefit is the reduction in our external failure costs. Every defect in a batch of 10,000 units costs us $1,000- warranty work, lost sales, a customer service department, and so on. If we can reach the material and labor productivity goals, our defects will drop from 20 per batch to 5 per batch. Required: 1. Discuss the advantages of using only operational measures of productivity for controlling shop-level activities. 2. Assume that the batch productivity statistics are met by the end of the year. Calculate the change in a batch's profits from the beginning of the year to the end that is attributable to changes in materials and labor productivity. 3. Now, assume that three inputs are to be evaluated: materials, labor, and quality. Quality is measured by the number of defects per batch. Calculate the change in a batch's profits from the beginning of the year to the end that is attributable to changes in productivity of all three inputs. Do you agree that quality is an input? Explain