Answered step by step

Verified Expert Solution

Question

1 Approved Answer

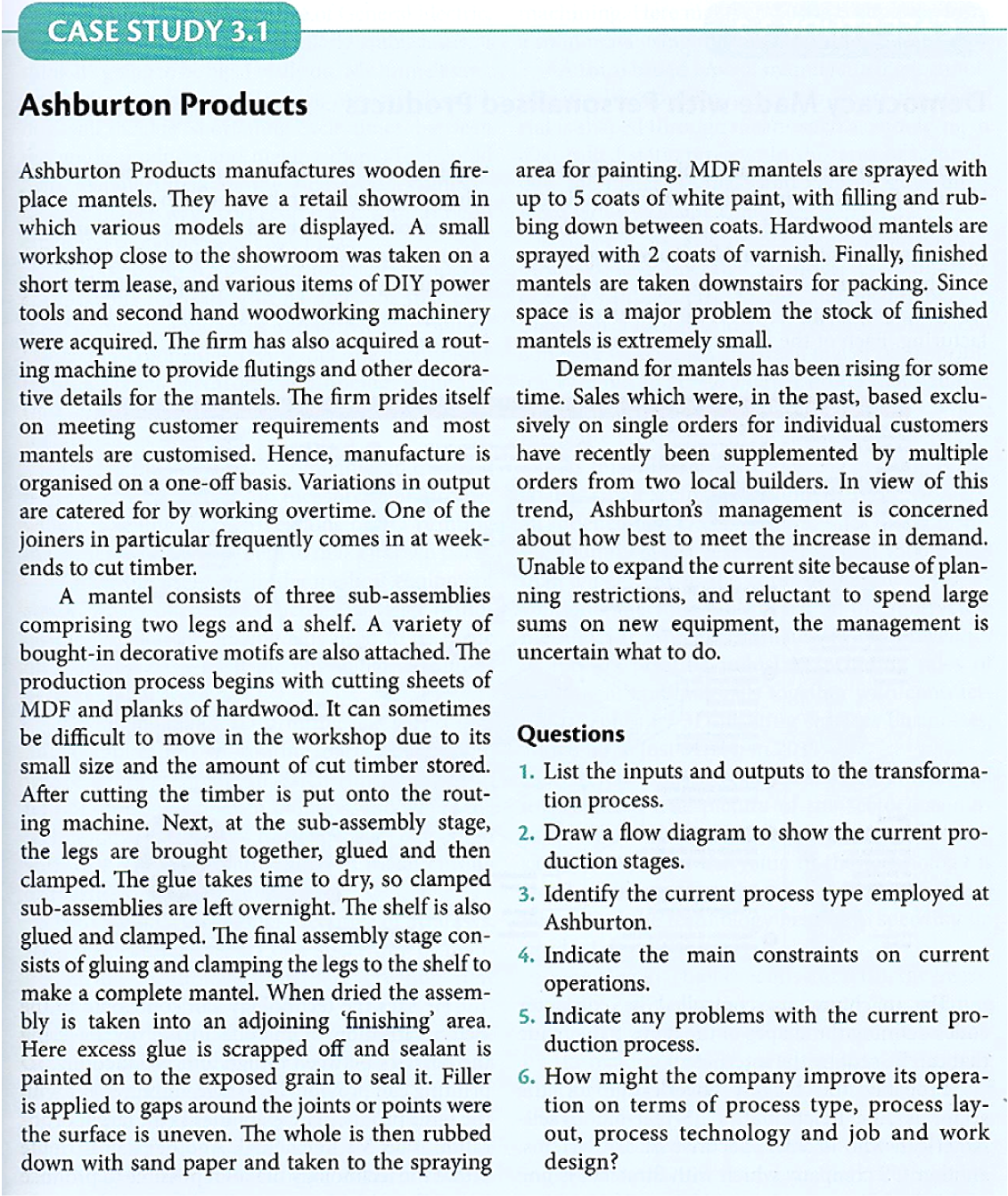

Ashburton Products Ashburton Products manufactures wooden fire - place mantels. They have a retail showroom in which various models are displayed. A small workshop close

Ashburton Products

Ashburton Products manufactures wooden fire

place mantels. They have a retail showroom in

which various models are displayed. A small

workshop close to the showroom was taken on a

short term lease, and various items of DIY power

tools and second hand woodworking machinery

were acquired. The firm has also acquired a rout

ing machine to provide flutings and other decora

tive details for the mantels. The firm prides itself

on meeting customer requirements and most

mantels are customised. Hence, manufacture is

organised on a oneoff basis. Variations in output

are catered for by working overtime. One of the

joiners in particular frequently comes in at week

ends to cut timber.

A mantel consists of three subassemblies

comprising two legs and a shelf. A variety of

boughtin decorative motifs are also attached. The

production process begins with cutting sheets of

MDF and planks of hardwood. It can sometimes

be difficult to move in the workshop due to its

small size and the amount of cut timber stored.

After cutting the timber is put onto the rout

ing machine. Next, at the subassembly stage,

the legs are brought together, glued and then

clamped. The glue takes time to dry, so clamped

subassemblies are left overnight. The shelf is also

glued and clamped. The final assembly stage con

sists of gluing and clamping the legs to the shelf to

make a complete mantel. When dried the assem

bly is taken into an adjoining 'finishing' area.

Here excess glue is scrapped off and sealant is

painted on to the exposed grain to seal it Filler

is applied to gaps around the joints or points were

the surface is uneven. The whole is then rubbed

down with sand paper and taken to the spraying

area for painting. MDF mantels are sprayed with

up to coats of white paint, with filling and rub

bing down between coats. Hardwood mantels are

sprayed with coats of varnish. Finally, finished

mantels are taken downstairs for packing. Since

space is a major problem the stock of finished

mantels is extremely small.

Demand for mantels has been rising for some

time. Sales which were, in the past, based exclu

sively on single orders for individual customers

have recently been supplemented by multiple

orders from two local builders. In view of this

trend, Ashburton's management is concerned

about how best to meet the increase in demand.

Unable to expand the current site because of plan

ning restrictions, and reluctant to spend large

sums on new equipment, the management is

uncertain what to do

Questions

List the inputs and outputs to the transforma

tion process.

Draw a flow diagram to show the current pro

duction stages.

Identify the current process type employed at

Ashburton.

Indicate the main constraints on current

operations.

Indicate any problems with the current pro

duction process.

How might the company improve its opera

tion on terms of process type, process lay

out, process technology and job and work

design?

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started