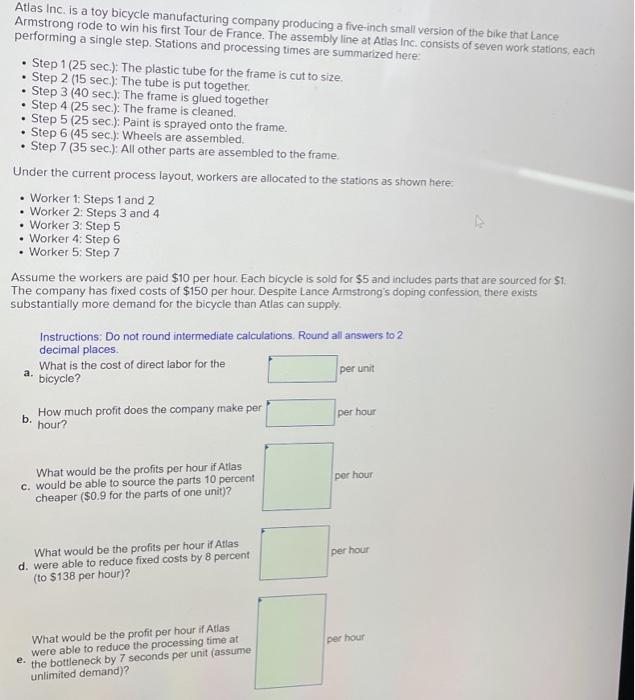

Atlas Inc. is a toy bicycle manufacturing company producing a five-inch small version of the bike that Lance Armstrong rode to win his first Tour de France. The assembly line at Atlas Inc. consists of seven work stations, each performing a single step. Stations and processing times are summarized here: Step 1(25 sec.): The plastic tube for the frame is cut to size. Step 2 (15 sec.): The tube is put together Step 3 (40 sec.). The frame is glued together Step 4 (25 sec.). The frame is cleaned Step 5 (25 sec.). Paint is sprayed onto the frame. Step 6 (45 sec.): Wheels are assembled. Step 7 (35 sec.). All other parts are assembled to the frame. Under the current process layout, workers are allocated to the stations as shown here: Worker 1: Steps 1 and 2 Worker 2: Steps 3 and 4 Worker 3: Step 5 Worker 4: Step 6 Worker 5: Step 7 Assume the workers are paid $10 per hour. Each bicycle is sold for $5 and includes parts that are sourced for $1. The company has fixed costs of $150 per hour. Despite Lance Armstrong's doping confession there exists substantially more demand for the bicycle than Atlas can supply: Instructions: Do not round intermediate calculations. Round all answers to 2 decimal places What is the cost of direct labor for the bicycle? a. per unit b. How much profit does the company make per hour? per hour per hour What would be the profits per hour if Atlas c. would be able to source the parts 10 percent cheaper ($0.9 for the parts of one unit)? per hour What would be the profits per hour if Atlas d. were able to reduce fixed costs by 8 percent (to $138 per hour)? per hour What would be the profit per hour if Atlas were able to reduce the processing time at e. the bottleneck by 7 seconds per unit (assume unlimited demand)? Atlas Inc. is a toy bicycle manufacturing company producing a five-inch small version of the bike that Lance Armstrong rode to win his first Tour de France. The assembly line at Atlas Inc. consists of seven work stations, each performing a single step. Stations and processing times are summarized here: Step 1(25 sec.): The plastic tube for the frame is cut to size. Step 2 (15 sec.): The tube is put together Step 3 (40 sec.). The frame is glued together Step 4 (25 sec.). The frame is cleaned Step 5 (25 sec.). Paint is sprayed onto the frame. Step 6 (45 sec.): Wheels are assembled. Step 7 (35 sec.). All other parts are assembled to the frame. Under the current process layout, workers are allocated to the stations as shown here: Worker 1: Steps 1 and 2 Worker 2: Steps 3 and 4 Worker 3: Step 5 Worker 4: Step 6 Worker 5: Step 7 Assume the workers are paid $10 per hour. Each bicycle is sold for $5 and includes parts that are sourced for $1. The company has fixed costs of $150 per hour. Despite Lance Armstrong's doping confession there exists substantially more demand for the bicycle than Atlas can supply: Instructions: Do not round intermediate calculations. Round all answers to 2 decimal places What is the cost of direct labor for the bicycle? a. per unit b. How much profit does the company make per hour? per hour per hour What would be the profits per hour if Atlas c. would be able to source the parts 10 percent cheaper ($0.9 for the parts of one unit)? per hour What would be the profits per hour if Atlas d. were able to reduce fixed costs by 8 percent (to $138 per hour)? per hour What would be the profit per hour if Atlas were able to reduce the processing time at e. the bottleneck by 7 seconds per unit (assume unlimited demand)