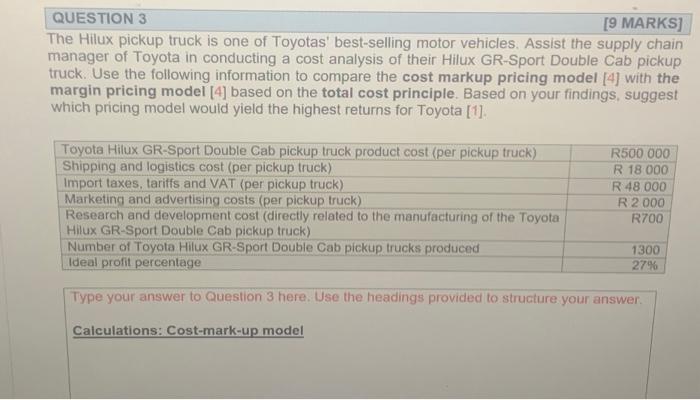

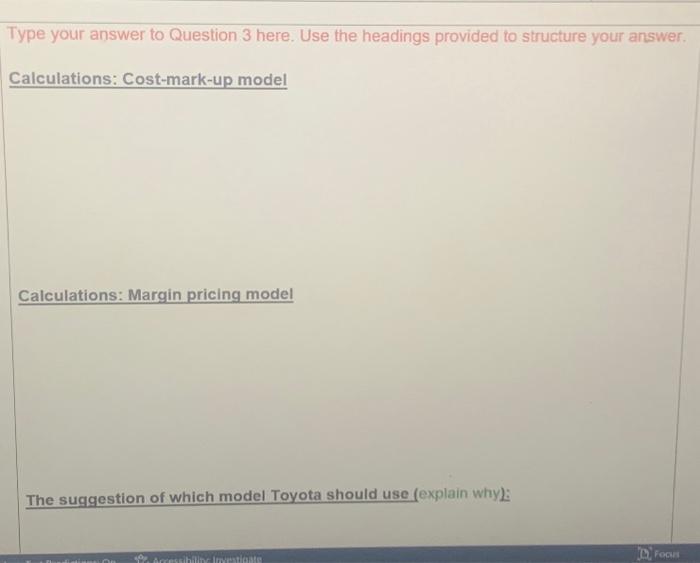

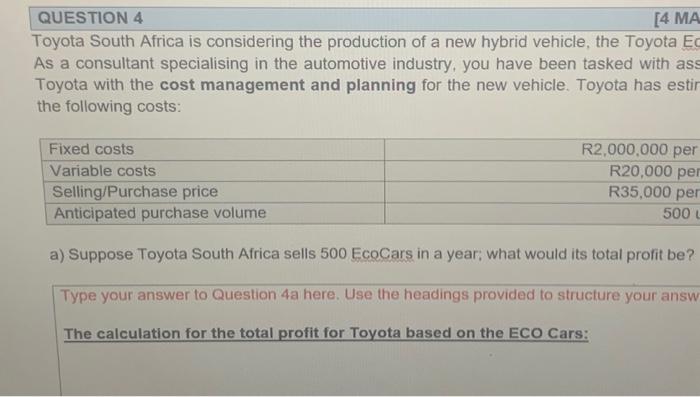

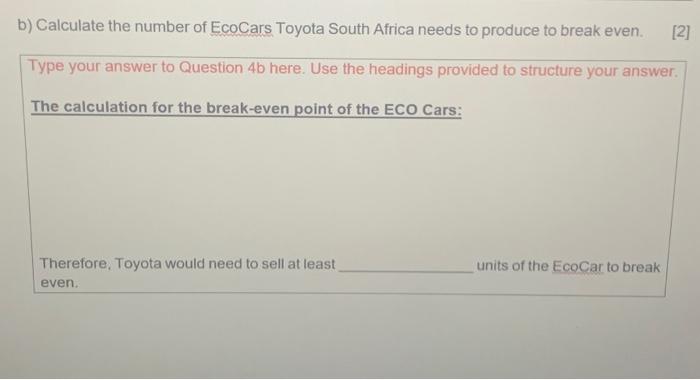

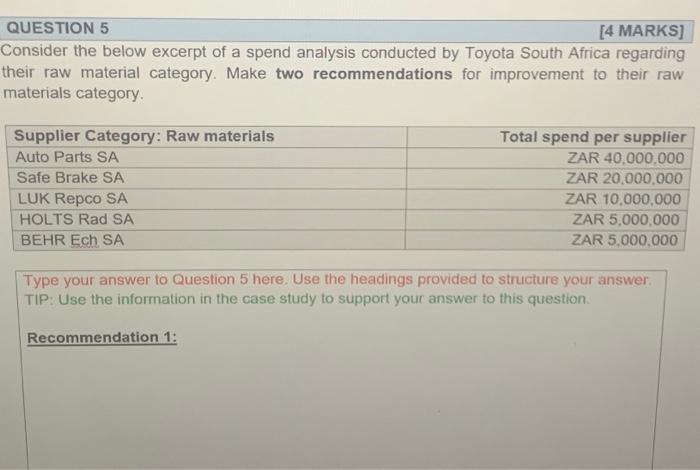

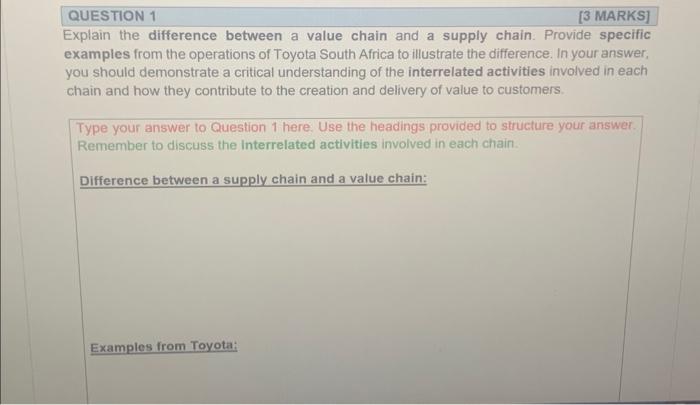

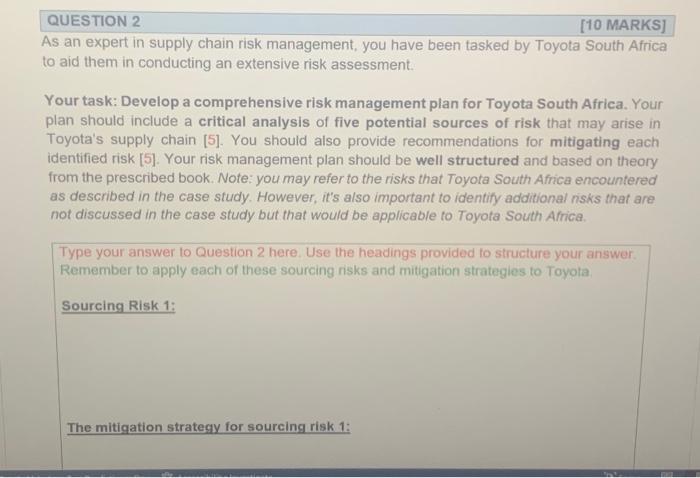

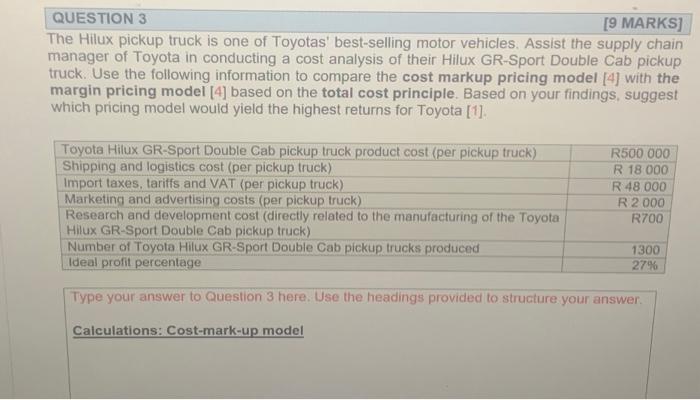

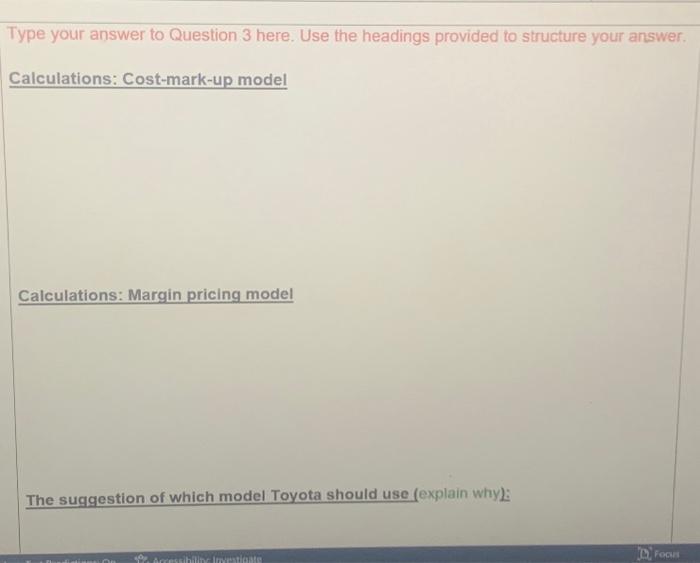

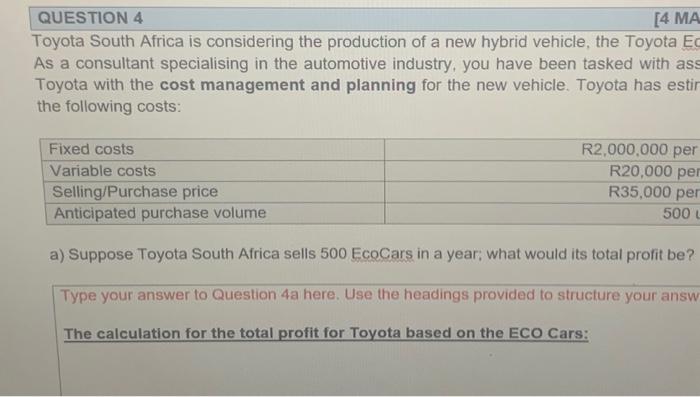

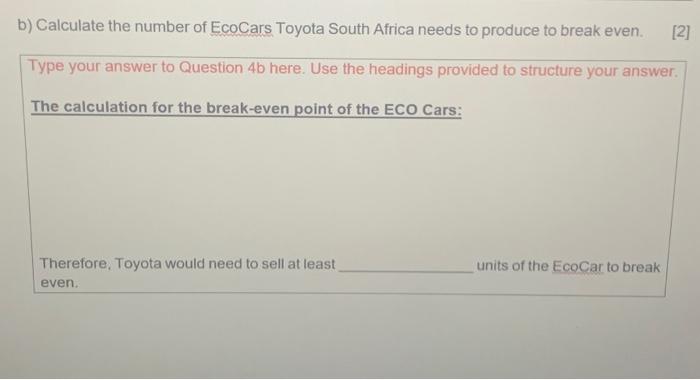

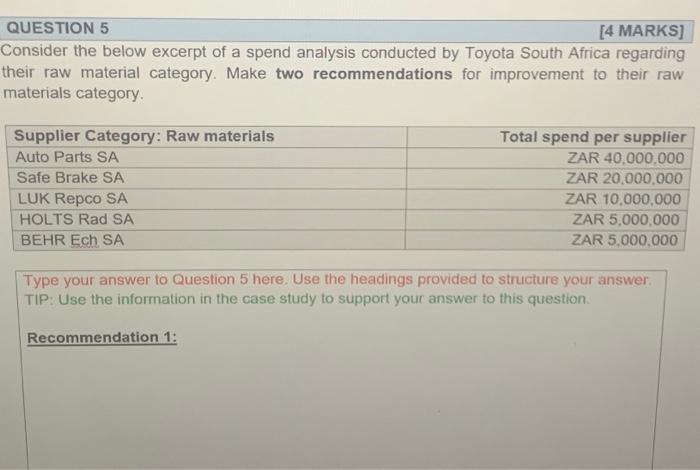

CASE STUDY Driving Success: How Toyota South Africa Navigated Supply Chain Disruptions Toyota South Africa is one of the leading automobile manufacturers in the country. Its supply chain is an essential component of its value chain, encompassing all activities involvod in creating and delivering value to customers. Raw materials and components are sourced from a network of global and local suppliers. After assembly into finished products in the manufacturing plants, they are stored in warehouses before being transported to dealerships or customers via various modes of transportation. However, supply chains are complex, and disruptions can occur, affecting various aspects of the company's operations. In 2019. Toyota South Africa encountered a significant challenge due to the shortage of critical manufacturing components required to produce its vehicles. The root cause of this problem was the company's over-reliance on a single supplier for some of its critical components. The supplier in question, Auto Parts South Africa (ASA), was based in Durban and their employees embarked on a large-scale strike, which resulted in a shortage of manufacturing components such as brake pedals, catalytic converters, and fuel tanks required for manufacturing models such as the Corolla, Fortuner, and Hilux. The Hilux is Toyota South Africa's most popular vehicle. During the strike, Toyota lost the production of approximately 6,000 vehicles, which led to a decline in sales, especially for its best-selling Hilux. Consequently, the company had to reduce its production capacity, temporarily lay off some employees and invest in altemative suppliers to ensure a steady supply of parts: These measures required additional resources and expertise from the purchasing department to manage the negotiations and coordinate with the new suppliers. The process of identifying and onboarding new suppliers was not without challenges, and it took some time before the supply of parts was fully restored. The incident highlighted the importance of effective communication, negotiation, and coltaboration with suppliors and other stakeholders involved in the supply chain. in 2022, the automotive industry in South Africa was hit yet again, this time by a devastating natural disaster, as heavy rainfall and flooding in the KwaZulu-Natal region caused widespread damage to infrastructure, including roads, bridges, and bulldings, with the city of Durban being particularly affected. The Toyota plant located in Prospecton. Durban, was severely impacted, resulting in irreparable harm to 88% of the production vehicies on site and significant damage to production lines, equipment, and materials. In addition to the damage inflicted on Toyota's faciities, the floods also caused major logistical challenges, affecting both the inbound movement of automotive parts and the outbound delivery of finished vehicles via the port of Durban. Although normal port operationa resumed relatively quickly. significant backlogs caused by disruptions to the multimodal transport network resulted in strained import and export deliveries for some time. It was reparted that Toyota experienced losses of around 45,000 vehicles, and hundreds of brand-new cars were rendered unusabie due to flood damage. To prepare for future disruptions, Toyota made a significant investment in an information system that provides real-time data on the supply chain, production, and sales. This investment enabled the company to monitor the supply chain and empowered Toyota to promptly take corrective actions in case of future disruptions. Additionally, the company conducted extensive risk assessments and developed several strategies to deal with disruptions. One such strategy was the investment in supply chain measurement tools to monitor and measure the supply chain's performance and identify risks early in the disnuption process. Toyota also used a scorecard system to evaluate the performance of its new suppliers based on metrics like quality, delivery, and cost. These proactive measures helped Toyota mitigate the risk of stockouts and identify bottlenecks in the supply chain, allowing them to work with suppliers to improve their performance. Sources: hitps:/lwww limeslive.c0 za/motoringinews/2023-01-26-these-were-south-africas-mostpopular-cars-ol-2022 hittps: iltopauto. co zalfeatures/45185/lovota-south-africa-recovering-anter-factory-flood-88-ofcars-written-off https:/lmedia toy-backendico zi/pdfi/teporis/. SustainabilityReport pat https / (wuw bizcommunity com/Aiticle/196/486/227878.himl [PLEASE SCROLL DOWN FOR ASSESSMENT S QUESTIONS] Explain the difference between a value chain and a supply chain. Provide specific examples from the operations of Toyota South Africa to illustrate the difference. In your answer, you should demonstrate a critical understanding of the interrelated activities involved in each chain and how they contribute to the creation and delivery of value to customers. Type your answer to Question 1 here. Use the headings provided to structure your answer. Remember to discuss the Interrelated activities involved in each chain. Difference between a supply chain and a value chain: Examples from Toyota: As an expert in supply chain risk management, you have been tasked by Toyota South Africa to aid them in conducting an extensive risk assessment. Your task: Develop a comprehensive risk management plan for Toyota South Africa. Your plan should include a critical analysis of five potential sources of risk that may arise in Toyota's supply chain [5]. You should also provide recommendations for mitigating each identified risk [5]. Your risk management plan should be well structured and based on theory from the prescribed book. Note: you may refer to the risks that Toyota South Africa encountered as described in the case study. However, it's also important to identify additional risks that are not discussed in the case study but that would be applicable to Toyota South Africa. The Hilux pickup truck is one of Toyotas' best-selling motor vehicles. Assist the supply chain manager of Toyota in conducting a cost analysis of their Hilux GR-Sport Double Cab pickup truck. Use the following information to compare the cost markup pricing model [4] with the margin pricing model [4] based on the total cost principle. Based on your findings, suggest which pricing model would yield the highest returns for Toyota [1]. Type your answer to Question 3 here. Use the headings provided to structure your answer. Calculations: Cost-mark-up model Type your answer to Question 3 here. Use the headings provided to structure your answer. Calculations: Cost-mark-up model Calculations: Margin pricing model Toyota South Africa is considering the production of a new hybrid vehicle, the Toyota Ec As a consultant specialising in the automotive industry, you have been tasked with ass Toyota with the cost management and planning for the new vehicle. Toyota has estir the following costs: a) Suppose Toyota South Africa sells 500 EcoCars in a year; what would its total profit be? Type your answer to Question 4a here. Use the headings provided to structure your answ The calculation for the total profit for Toyota based on the ECO Cars: b) Calculate the number of EcoCars Toyota South Africa needs to produce to break even. Type your answer to Question 4b here. Use the headings provided to structure your answer. The calculation for the break-even point of the ECO Cars: Therefore, Toyota would need to sell at least units of the EcoCar to break even. Consider the below excerpt of a spend analysis conducted by Toyota South Africa regarding their raw material category. Make two recommendations for improvement to their raw materials category. Type your answer to Question 5 here. Use the headings provided to structure your answer. TIP: Use the information in the case study to support your answer to this question. Recommendation 1