CASE STUDY:U.S.Stroller:Lean(see Part VII of the textbook)

Discussion Questions:

- How would you describe the current situation facing U. S.Stroller?

- What are thepro's and con's of the options presented in the case?

- What will be the impact of these options on the MRP system currently in use?

- What option do you recommend and why?

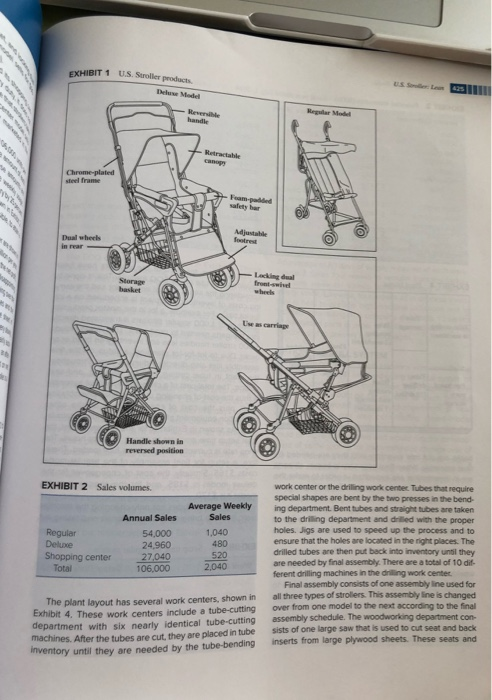

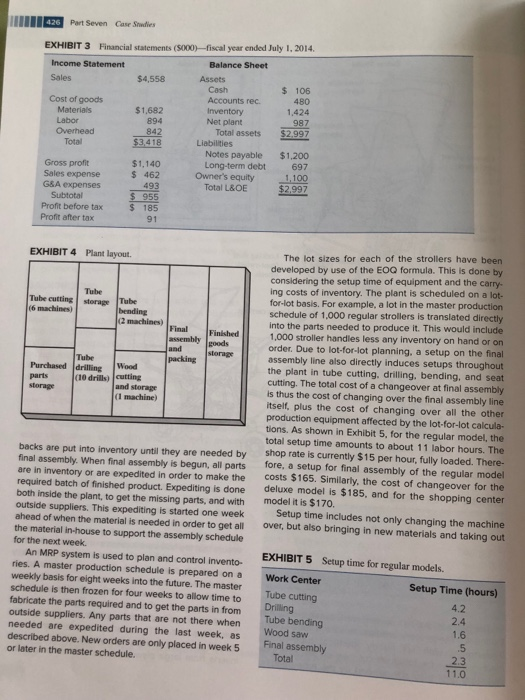

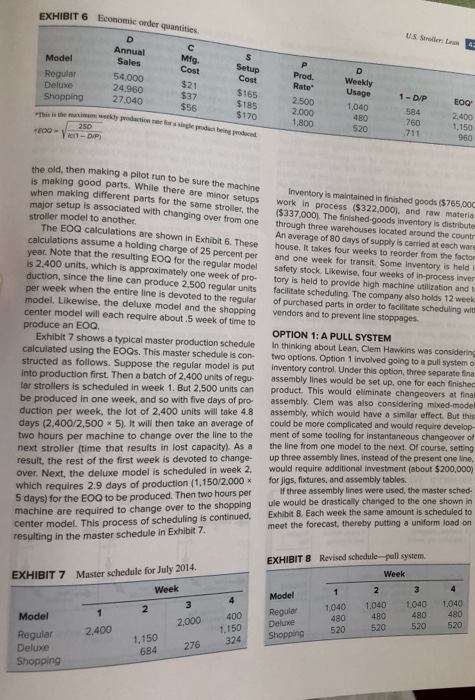

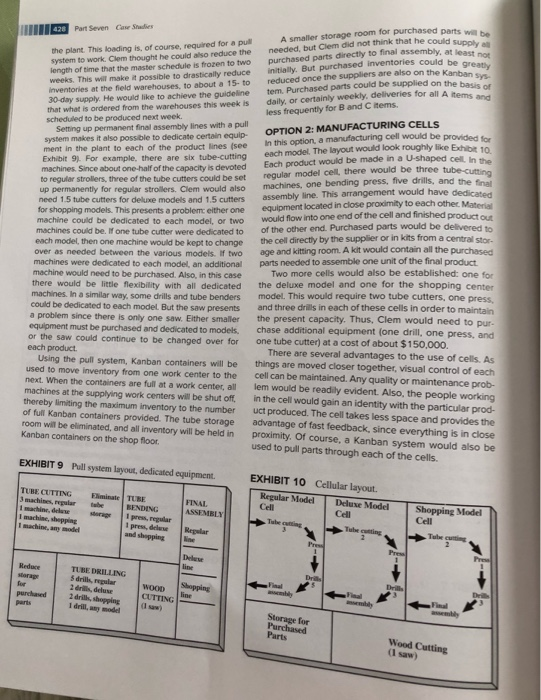

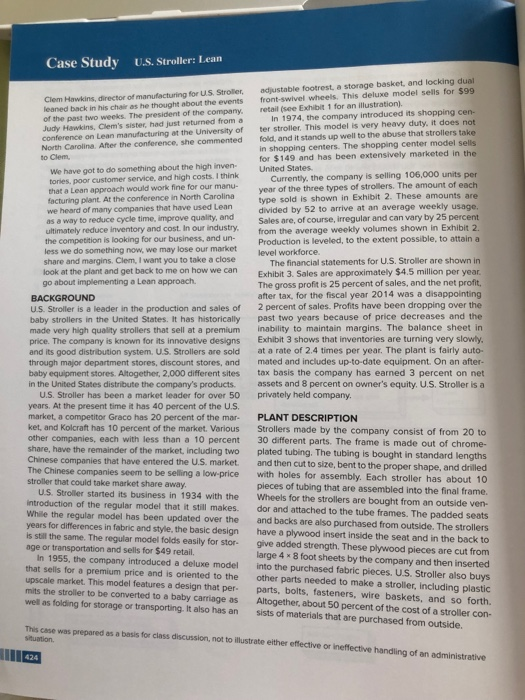

EXHIBIT 1 U.S. Stroller products, Hegular Model handle Retractable canopy Chrome-plated - Foam-padded sales har Dual wheels Adjustable in rear Lacking dual Use a carriage Handle shown in reversed position EXHIBIT 2 Sales volumes. work center of the drilling work center. Tubes that require Average Weekly special shapes are bent by the two provees in the bend- ing department. Bent tubes and straight tubes are taken Annual Sales Sales to the drilling department and drilled with the proper Regular 54.000 1.040 holes. Jigs are used to speed up the process and to Deline 24.960 480 ensure that the holes are located in the right places. The Shopping center 27,040 520 drilled tubes are then put back into inventory until they Total 106,000 2,040 are needed by final assembly. There are a total of 10 dif- ferent drilling machines in the drilling work center. Final assembly consists of one assembly line used for The plant layout has several work centers, shown in all three types of strollers. This assembly line is changed Exhibit 4. These work centers include a tube-cutting over from one model to the next according to the final department with six nearly identical tube-cutting assembly schedule. The woodworking department con- machines. After the tubes are cut, they are placed in tube sists of one large saw that is used to cut seat and back inventory until they are needed by the tube-bending inserts from large plywood sheets. These seats and426 Part Seven Case Studies EXHIBIT 3 Financial statements ($000)-fiscal year ended July 1, 2014. Income Statement Balance Sheet Sales $4,558 Assets Cash $ 106 Cost of goods Accounts rec. 480 Materials $1.682 Inventory 1,424 Labor 894 Net plant 987 Overhead 842 Total assets $2.997 Total $3,418 Liabilities Notes payable $1,200 Gross profit $1.140 Long-term debt 697 Sales expense $ 462 Owner's equity 1,100 G&A expenses 493 Total L&OE $2.997 Subtotal 955 Profit before tax 185 Profit after tax 91 EXHIBIT 4 Plant layout. The lot sizes for each of the strollers have been developed by use of the EOQ formula. This is done by considering the setup time of equipment and the carry- Tube Ing costs of inventory. The plant is scheduled on a lot- Tube cutting storage Tube for-lot basis. For example, a lot in the master production it machines bending schedule of 1,000 regular strollers is translated directly (2 machines Final into the parts needed to produce it. This would include Finished assembly 1,000 stroller handles less any inventory on hand or on goods order. Due to lot-for-lot planning. a setup on the final Tube packing assembly line also directly induces setups throughout Purchased drilling the plant in tube cutting. drilling, bending, and seat parts (10 drills) cutting cutting. The total cost of a changeover at final assembly and storage (I machine) is thus the cost of changing over the final assembly line itself, plus the cost of changing over all the other production equipment affected by the lot-for-lot calcula- tions. As shown in Exhibit 5. for the regular model, the total setup time amounts to about 11 labor hours. The backs are put into inventory until they are needed by shop rate is currently $15 per hour, fully loaded. There- final assembly. When final assembly is begun, all parts fore, a setup for final assembly of the regular model are in inventory or are expedited in order to make the costs $165. Similarly, the cost of changeover for the required batch of finished product. Expediting is done deluxe model is $185, and for the shopping center both inside the plant, to get the missing parts, and with model it is $170. outside suppliers. This expediting is started one week ahead of when the material is needed in order to get all Setup time Includes not only changing the machine the material in-house to support the assembly schedule over, but also bringing in new materials and taking out for the next week. An MRP system is used to plan and control invento- EXHIBIT 5 Setup time for regular models. ries. A master production schedule is prepared on a weekly basis for eight weeks into the future. The master Work Center Setup Time (hours) schedule is then frozen for four weeks to allow time to Tube cutting fabricate the parts required and to get the parts in from Drilling 4.2 outside suppliers. Any parts that are not there when Tube bending 2.4 needed are expedited during the last week, as Wood saw 1.6 described above. New orders are only placed in week 5 Final assembly .5 or later in the master schedule. Total 2.3 11.0EXHIBIT 6 Economic order quantities. D 4 Model Annual C Sales Mig. Regular Cost Setup 54,000 Cost Prod. $21 Rate" Weekly Deluxe 24.960 $165 Usage Shopping 27.040 $37 2.500 1 = D/P 1,040 EOQ $185 $170 2.000 1,800 480 584 760 2,400 "This is the maximum weekly production rate for a single product bring produced 1, 150 250 520 .711 960 the old, then making a pilot run to be sure the machine is making good parts. While there are minor setups when making different parts for the same stroller, the Inventory is maintained in finished goods ($765,00 major setup is associated with changing over from one work in process ($322,000]. and raw materia stroller model to another. ($337,000). The finished goods inventory is distribute through three warehouses located around the countr The EO@ calculations are shown in Exhibit 6. These An average of 80 days of supply is carried at each war calculations assume a holding charge of 25 percent per house. It takes four weeks to reorder from the facto year. Note that the resulting EOQ for the regular model and one week for transit. Some Inventory Is held is 2,400 units, which is approximately one week of pro- safety stock. Likewise, four weeks of in-process inve duction, since the line can produce 2.500 regular units tory is held to provide high machine utilization and per week when the entire line is devoted to the regular facilitate scheduling. The company also holds 12 week model. Likewise, the deluxe model and the shopping of purchased parts in order to facilitate scheduling wit center model will each require about .5 week of time to vendors and to prevent line stoppages. produce an EOQ. Exhibit 7 shows a typical master production schedule OPTION 1: A PULL SYSTEM calculated using the EOQs. This master schedule is con- In thinking about Lean, Clem Hawkins was considering two options. Option 1 involved going to a pull system structed as follows. Suppose the regular model is put inventory control, Under this option, three separate fina Into production first. Then a batch of 2,400 units of regu- assembly lines would be set up, one for each finished lar strollers is scheduled in week 1. But 2,500 units can product. This would eliminate changeovers at final be produced in one week, and so with five days of pro- assembly. Clem was also considering mixed-model duction per week, the lot of 2,400 units will take 4.8 assembly, which would have a similar effect. But this days (2,400/2,500 x 5). It will then take an average of could be more complicated and would require develop two hours per machine to change over the line to the ment of some tooling for instantaneous changeover of next stroller (time that results in lost capacity). As a the line from one model to the next. Of course, setting result, the rest of the first week is devoted to change- up three assembly lines, Instead of the present one line, over. Next, the deluxe model is scheduled in week 2, would require additional investment (about $200,000) which requires 2.9 days of production (1, 150/2,000 * for jigs, fixtures, and assembly tables. If three assembly lines were used, the master sched- 5 days) for the EOQ to be produced. Then two hours per ule would be drastically changed to the one shown in machine are required to change over to the shopping Exhibit B. Each week the same amount is scheduled to center model. This process of scheduling is continued, meet the forecast, thereby putting a uniform load on resulting in the master schedule in Exhibit 7. EXHIBIT 8 Revised schedule-pull system. EXHIBIT 7 Master schedule for July 2014. Week Week 2 3 Model 1.040 1.040 1.040 1,040 2 3 400 Regular 480 480 480 Model 2,000 1.150 Deluxe 180 520 520 520 520 Regular 2.400 1,150 374 Shopping Deluxe 684 276 Shopping438 Part Seven Case Studies A smaller storage room for purchased parts will be the plant. This loading is, of course, required for a pull needed, but Clem did not think that he could supply all system to work. Clem thought he could also reduce the purchased parts directly to final assembly. at least not length of time that the master schedule is frozen to two initially. But purchased inventories could be greaty weeks. This will make it possible to drastically reduce reduced once the suppliers are also on the Kanban sys- Inventories at the field warehouses. to about a 15- to tem. Purchased parts could be supplied on the basis of 30-day supply. He would like to achieve the guideline daily, or certainly weekly. deliveries for all A items and that what is ordered from the warehouses this week is less frequently for B and C Hems. scheduled to be produced next week. Setting up permanent final assembly lines with a pull OPTION 2: MANUFACTURING CELLS system makes it also possible to dedicate certain equip- In this option, a manufacturing cell would be provided for ment in the plant to each of the product lines (see each model. The layout would look roughly like Exhibit 10. Exhibit 9) For example. there are six tube-cutting Each product would be made in a U-shaped cell. In the machines. Since about one-half of the capacity is devoted regular model cell, there would be three tube-cutting to regular strollers, three of the tube cutters could be set machines, one bending press, five drills, and the final up permanently for regular strollers. Clem would also assembly line. This arrangement would have dedicated need 15 tube cutters for deluxe models and 1.5 cutters for shopping models. This presents a problem either one equipment located in close proximity to each other Material machine could be dedicated to each model, or two would flow into one end of the cell and finished product out machines could be. If one tube cutter were dedicated to of the other end. Purchased parts would be delivered to each model, then one machine would be kept to change the cell directly by the supplier or in kits from a central stor- over as needed between the various models. If two age and kitting room. A kit would contain all the purchased machines were dedicated to each model, an additional parts needed to assemble one unit of the final product machine would need to be purchased. Also, in this case Two more cells would also be established: one for there would be little flexibility with all dedicated the deluxe model and one for the shopping center machines. In a similar way, some drills and tube benders model. This would require two tube cutters, one press, could be dedicated to each model. But the saw presents and three drills in each of these cells in order to maintain a problem since there is only one saw. Either smaller the present capacity. Thus, Clem would need to pur- equipment must be purchased and dedicated to models. chase additional equipment (one drill, one press, and or the saw could continue to be changed over for one tube cutter) at a cost of about $150,000. each product. There are several advantages to the use of cells. As Using the pull system, Kanban containers will be things are moved closer together, visual control of each used to move inventory from one work center to the next. When the containers are full at a work center, all cell can be maintained. Any quality or maintenance prob- machines at the supplying work centers will be shut off, lem would be readily evident. Also, the people working thereby limiting the maximum inventory to the number in the cell would gain an identity with the particular prod- of full Kanban containers provided. The tube storage uct produced. The cell takes less space and provides the room will be eliminated, and all inventory will be held in advantage of fast feedback, since everything is in close Kanban containers on the shop floor. proximity. Of course, a Kanban system would also be used to pull parts through each of the cells. EXHIBIT 9 Pull system layout, dedicated equipment. EXHIBIT 10 Cellular layout. TUBE CUTTING J machines, regular Eliminate TUBE FINAL Regular Model Cell Deluxe Model Shopping Model machine, dilate BENDING Cell I machine, chopping I press, regular ASSEMBLY Tube runing Cell machine, any minded I press, deluxe Tube cutting and shopping Regular Tube cutting Reduce ling TUBE DRILLING drills, Freular Shopping Final 3 drills, deluse ling -Final purchased 1 drill, shopping CUTTING -Final I drill, any model Storage for Purchased Parts Wood Cutting (I sawCase Study U.S. Stroller: Lean Clom Hawkins, director of manufacturing for U.S. Stroller, adjustable footrest. a storage basket, and locking dual leaned back in his chair as he thought about the events front-swivel wheels, This deluxe model sells for $99 of the past two weeks. The president of the company retail (ope Exhibit 1 for an illustration]. Judy Hawkins, Clem's sister, had just returned from a In 1974, the company introduced its shopping cen- conference on Lean manufacturing at the University of ter stroller. This model is very heavy duty. it does not North Carolina. After the conference. she commented fold, and it stands up well to the abuse that strollers take in shopping centers. The shopping center model sells to Claim for $149 and has been extensively marketed in the We have got to do something about the high inven- United States. tories, poor customer service, and high costs. I think Currently, the company is selling 106,000 units per that a Lean approach would work fine for our manu- year of the three types of strollers. The amount of each facturing plant. At the conference in North Carolina type sold is shown in Exhibit 2. These amounts are we heard of many companies that have used Lean divided by 52 to arrive at an average weekly usage, as a way to reduce cycle time, improve quality, and ultimately reduce inventory and cost. In our industry. Sales are, of course, irregular and can vary by 25 percent the competition is looking for our business, and un- from the average weekly volumes shown in Exhibit 2. less we do something now, we may lose our market Production is leveled, to the extent possible, to attain a share and margins, Clem, I want you to take a close level workforce. look at the plant and get back to me on how we can The financial statements for U.S. Stroller are shown in go about implementing a Lean approach. Exhibit 3. Sales are approximately $4.5 million per year. The gross profit is 25 percent of sales, and the net profit, BACKGROUND after tax, for the fiscal year 2014 was a disappointing U.S. Stroller is a leader in the production and sales of 2 percent of sales. Profits have been dropping over the baby strollers in the United States. It has historically past two years because of price decreases and the made very high quality strollers that sell at a premium inability to maintain margins. The balance sheet in price. The company is known for its innovative designs Exhibit 3 shows that inventories are turning very slowly. and its good distribution system. U.S. Strollers are sold at a rate of 2.4 times per year. The plant is fairly auto- through major department stores, discount stores, and mated and includes up-to-date equipment. On an after- baby equipment stores. Altogether, 2,000 different sites in the United States distribute the company's products. tax basis the company has earned 3 percent on net U.S. Stroller has been a market leader for over 50 assets and 8 percent on owner's equity. U.S. Stroller Is a privately held company. years. At the present time it has 40 percent of the U.S, market. a competitor Graco has 20 percent of the mar- kel, and Kolcraft has 10 percent of the market. Various PLANT DESCRIPTION other companies, each with less than a 10 percent Strollers made by the company consist of from 20 to share, have the remainder of the market, Including two 30 different parts. The frame is made out of chrome- Chinese companies that have entered the U.S. market. plated tubing. The tubing is bought in standard lengths The Chinese companies scom to be selling a low-price and then cut to size, bent to the proper shape, and drilled stroller that could take market share away, with holes for assembly. Each stroller has about 10 U.S. Stroller started its business in 1934 with the pieces of tubing that are assembled into the final frame. introduction of the regular model that it still makes. Wheels for the strollers are bought from an outside ven- While the regular model has been updated over the dor and attached to the tube frames. The padded seats years for differences in fabric and style, the basic design and backs are also purchased from outside. The strollers Is still the same. The regular model folds easily for store have a plywood insert inside the seat and in the back to age or transportation and sells for $49 retail. give added strength. These plywood pieces are cut from In 1955, the company introduced a deluxe model large 4 * 8 foot sheets by the company and then inserted that sells for a premium price and is oriented to the into the purchased fabric pieces. U.S. Stroller also buys upscale market. This model features a design that per- mits the stroller to be converted to a baby carriage as other parts needed to make a stroller, Including plastic well as folding for storage or transporting. It also has an parts, bolts, fasteners, wire baskets, and so forth. Altogether, about 50 percent of the cost of a stroller con- sists of materials that are purchased from outside. situation. This case was prepared as a basis for class discussion, not to illustrate either effective or ineffective handling of an administrative 424