8 91426 10 11 (CCM) builds furniture for a range of commercial customers. They build furniture used in hotels and department stores, on cruise

![Firm orders already received for this year are as follows in Table 3. PART IOF]) o tables in the first 20 works of 2020 Table](https://dsd5zvtm8ll6.cloudfront.net/si.experts.images/questions/2022/02/62186b85be587_1645767555840.jpg)

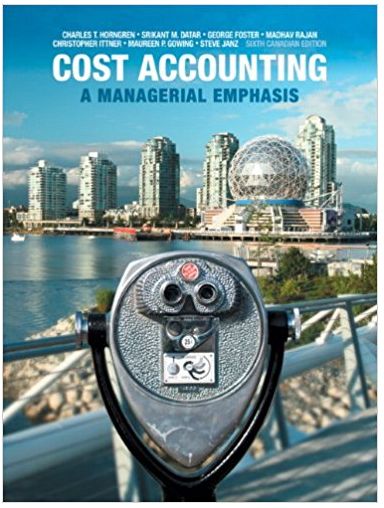

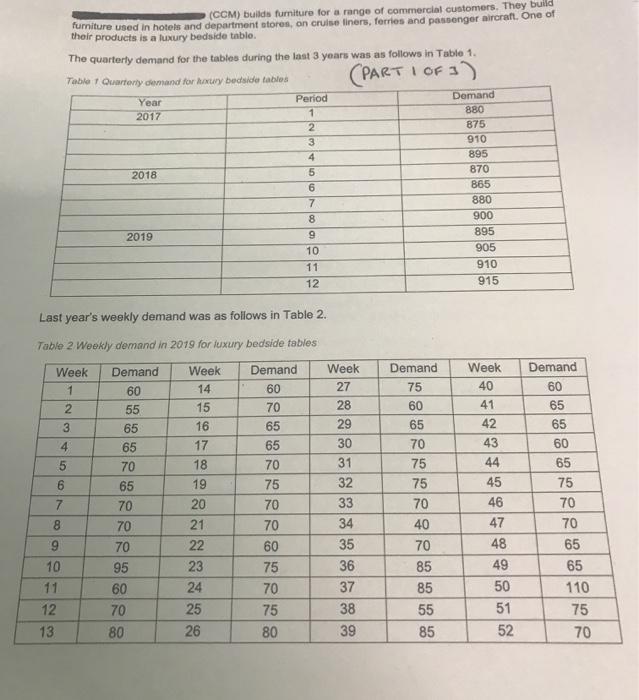

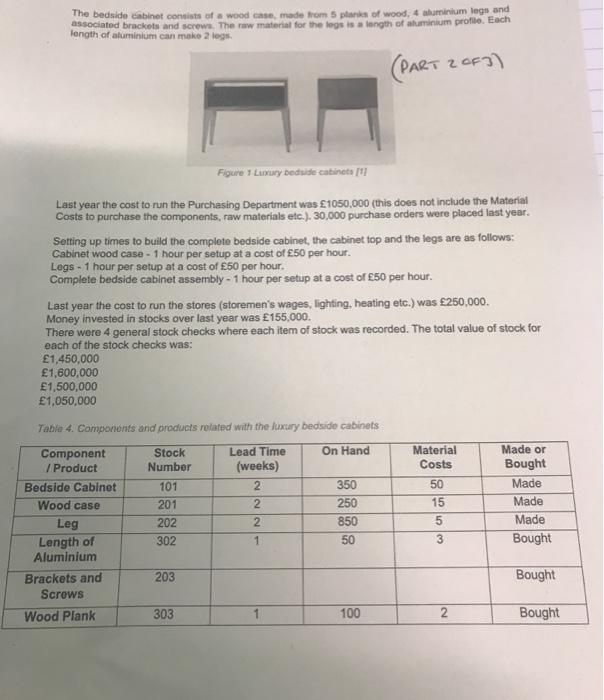

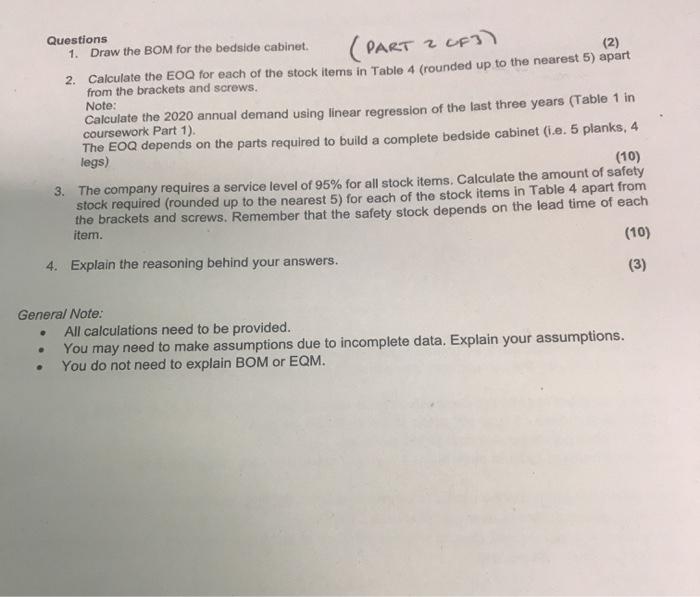

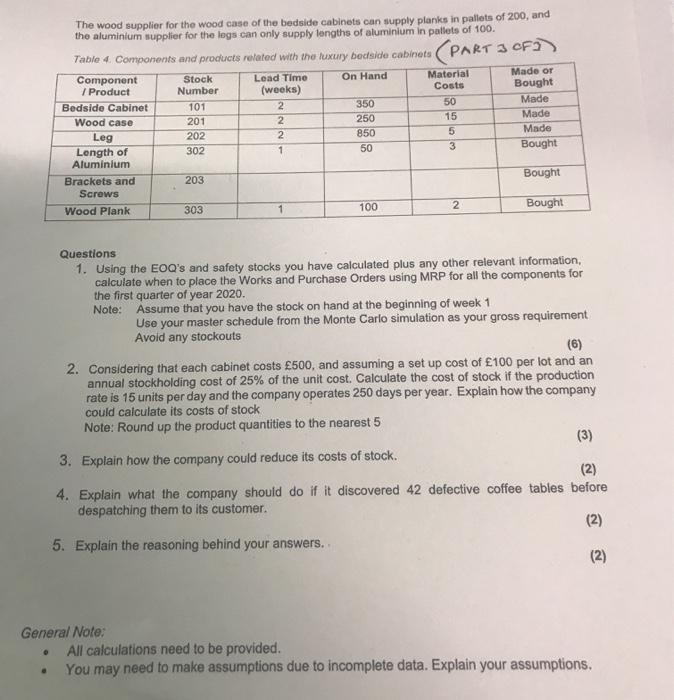

8 91426 10 11 (CCM) builds furniture for a range of commercial customers. They build furniture used in hotels and department stores, on cruise liners, ferries and passenger aircraft. One of their products is a luxury bedside tablo. 13 The quarterly demand for the tables during the last 3 years was as follows in Table 1. Table 1 Quarterly demand for luxury bedside tables (PART 1 OF 3) Last year's weekly demand was as follows in Table 2. Table 2 Weekly demand in 2019 for luxury bedside tables Demand Week Demand Week 1 60 14 2 34567 Year 2017 2018 2019 55 65 65 70 65 70 70 70 95 60 70 80 15 16 17 18 19 20 21 22 23 24 25 26 160 70 65 65 70 75 70 Period 1 2 3 4 70 60 75 70 75 80 5 6 7 8 9 10 11 12 Week 27 28 29 30 31 32 33 34 35 36 37 38 39 Demand 75 60 65 70 75 75 70 40 70 85 85 55 85 Demand 880 875 910 895 870 865 880 900 895 905 910 915 Week 4041 4243 44 45 46 47 48 49 50 51 52 Demand 60 65 65 60 65 75 70 70 65 65 110 75 70 Firm orders already received for this year are as follows in Table 3. Table 3 Firm orders for luxury bedside tables in the first 20 weeks of 2020 Week 11 12 e . Week 1 2 3 4 General Note: 5 6 7 8 9 10 Orders 60 70 50 80 40 60 80 110 13 14 15 16 17 18 19 20 PART IOF]) Orders 20 - Questions 1. Use Monte Carlo Simulation and Exponential Smoothing (plus any other techniques you feel are appropriate) to predict the weekly demand for the first 13 weeks (1st quarter) of 2020. Consider a=0.3 50 30 20 (7) 2. Combine the Forecast Demand with the Firm Orders to determine the Master Schedule. One for each technique. (5) 3. Explain the reasoning behind your answers, as well as which of the Master Schedules would represent closely the reality. (4) 4. Discuss if there are any disadvantages of using Monte Carlo Simulation, and compare your results with those of time series forecasting. (4) All calculations need to be provided. The time period of a quarter lasts for 13 weeks. You may need to make assumptions due to incomplete data. Explain your assumptions. You do not need to explain Monte Carlo Simulation or Time Series Analysis calculations. Limitations of the techniques used (e.g. Monte Carlo, time series analysis, etc.) should be focused in your problem, not the general limitations of the technique. The bedside cabinet consists of a wood case, made from 5 planks of wood, 4 aluminium legs and associated brackets and screws. The raw material for the legs is a length of aluminium profile. Each length of aluminium can make 2 legs. ( ) Figure 1 Luxury bedside cabinets [1] Last year the cost to run the Purchasing Department was 1050,000 (this does not include the Material Costs to purchase the components, raw materials etc.). 30,000 purchase orders were placed last year. Setting up times to build the complete bedside cabinet, the cabinet top and the legs are as follows: Cabinet wood case- 1 hour per setup at a cost of 50 per hour. Legs - 1 hour per setup at a cost of 50 per hour. Complete bedside cabinet assembly - 1 hour per setup at a cost of 50 per hour. Last year the cost to run the stores (storemen's wages, lighting, heating etc.) was 250,000. Money invested in stocks over last year was 155,000. There were 4 general stock checks where each item of stock was recorded. The total value of stock for each of the stock checks was: 1,450,000 1,600,000 1,500,000 1,050,000 Table 4. Components and products related with the luxury bedside cabinets On Hand Component / Product Lead Time (weeks) Bedside Cabinet Wood case Leg Length of Aluminium Brackets and Screws Wood Plank Stock Number 101 201 202 302 203 303 2227 1 1 350 250 850 50 100 Material Costs 50 15 53 lov 2 Made or Bought Made Made Made Bought Bought Bought Questions 1. Draw the BOM for the bedside cabinet. PART 2 CF3) (2) 2. Calculate the EOQ for each of the stock items in Table 4 (rounded up to the nearest 5) apart from the brackets and screws. Note: Calculate the 2020 annual demand using linear regression of the last three years (Table 1 in coursework Part 1). The EOQ depends on the parts required to build a complete bedside cabinet (i.e. 5 planks, 4 legs) (10) 3. The company requires a service level of 95% for all stock items. Calculate the amount of safety stock required (rounded up to the nearest 5) for each of the stock items in Table 4 apart from the brackets and screws. Remember that the safety stock depends on the lead time of each item. (10) (3) 4. Explain the reasoning behind your answers. General Note: All calculations need to be provided.. You may need to make assumptions due to incomplete data. Explain your assumptions. You do not need to explain BOM or EQM. The wood supplier for the wood case of the bedside cabinets can supply planks in pallets of 200, and the aluminium supplier for the legs can only supply lengths of aluminium in pallets of 100. Table 4. Components and products related with the luxury bedside cabinets (PART 3 CF3 Component On Hand Lead Time (weeks) / Product Bedside Cabinet 2 Wood case 0 Leg Length of Aluminium Brackets and Screws Wood Plank Stock Number General Note: 101 201 202 302 203 303 2 2 1 1 350 250 850 50 100 Material Costs 50 15 5 3 2 Made or Bought Made Made Made Bought Bought Bought Questions 1. Using the EOQ's and safety stocks you have calculated plus any other relevant information, calculate when to place the Works and Purchase Orders using MRP for all the components for the first quarter of year 2020. Note: Assume that you have the stock on hand at the beginning of week 1 Use your master schedule from the Monte Carlo simulation as your gross requirement Avoid any stockouts (6) 2. Considering that each cabinet costs 500, and assuming a set up cost of 100 per lot and an annual stockholding cost of 25% of the unit cost. Calculate the cost of stock if the production rate is 15 units per day and the company operates 250 days per year. Explain how the company could calculate its costs of stock Note: Round up the product quantities to the nearest 5 3. Explain how the company could reduce its costs of stock. (2) 4. Explain what the company should do if it discovered 42 defective coffee tables before despatching them to its customer. (2) 5. Explain the reasoning behind your answers.. (3) (2) All calculations need to be provided. You may need to make assumptions due to incomplete data. Explain your assumptions.

Step by Step Solution

3.45 Rating (161 Votes )

There are 3 Steps involved in it

Step: 1

Firstly have to Draw a BOM and calculate the EOQ Questions 1 Draw the BOM for the bedside cabinet A BOM Bill of Materials is a hierarchical representation of the components and subassemblies required ...

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started