Question

Consider a custom-order processing system consisting of two steps: In Step 1, we first assemble the product; then, in Step 2, we test and tune

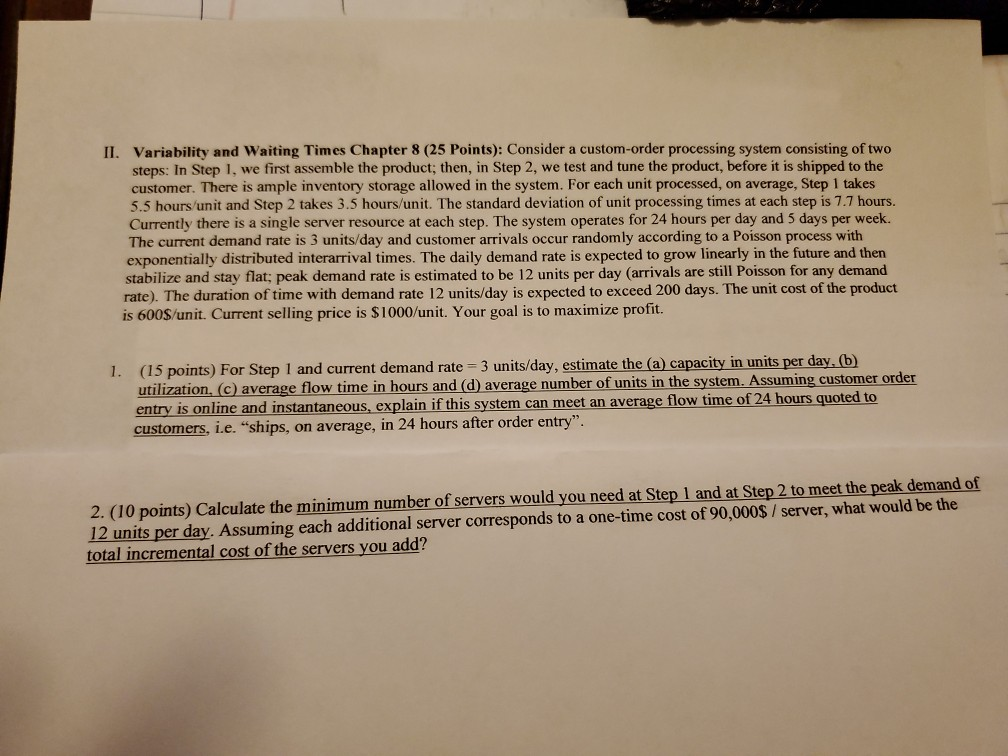

Consider a custom-order processing system consisting of two steps: In Step 1, we first assemble the product; then, in Step 2, we test and tune the product, before it is shipped to the customer. There is ample inventory storage allowed in the system. For each unit processed, on average, Step 1 takes 5.5 hours/unit and Step 2 takes 3.5 hours/unit. The standard deviation of unit processing times at each step is 7.7 hours. Currently there is a single server resource at each step. The system operates for 24 hours per day and 5 days per week. The current demand rate is 3 units/day and customer arrivals occur randomly according to a Poisson process with exponentially distributed interarrival times. The daily demand rate is expected to grow linearly in the future and then stabilize and stay flat; peak demand rate is estimated to be 12 units per day (arrivals are still Poisson for any demand rate). The duration of time with demand rate 12 units/day is expected to exceed 200 days. The unit cost of the product is 600$/unit. Current selling price is $1000/unit. Your goal is to maximize profit.

1) For Step 1 and current demand rate = 3 units/day, estimate the (a) capacity in units per day, (b) utilization, (c) average flow time in hours and (d) average number of units in the system. Assuming customer order entry is online and instantaneous, explain if this system can meet an average flow time of 24 hours quoted to customers, i.e. ships, on average, in 24 hours after order entry.

2) Calculate the minimum number of servers would you need at Step 1 and at Step 2 to meet the peak demand of 12 units per day. Assuming each additional server corresponds to a one-time cost of 90,000$ / server, what would be the total incremental cost of the servers you add?

II. Variability and Waiting Times Chapter 8 (25 Points): Consider a custom-order processing system consisting of two steps: In Step 1, we first assemble the product; then, in Step 2, we test and tune the product, before it is shipped to the customer. There is ample inventory storage allowed in the system. For each unit processed, on average, Step 1 takes 5.5 hours/unit and Step 2 takes 3.5 hours/unit. The standard deviation of unit processing times at each step is 7.7 hours. Currently there is a single server resource at each step. The system operates for 24 hours per day and 5 days per week. The current demand rate is 3 units/day and customer arrivals occur randomly according to a Poisson process with exponentially distributed interarrival times. The daily demand rate is expected to grow linearly in the future and then stabilize and stay flat; peak demand rate is estimated to be 12 units per day (arrivals are still Poisson for any demand rate). The duration of time with demand rate 12 units/day is expected to exceed 200 days. The unit cost of the product is 600$/unit. Current selling price is $1000/unit. Your goal is to maximize profit. 1. (15 points) For Step 1 and current demand rate = 3 units/day, estimate the (a) capacity in units per day. (b) utilization, (c) average flow time in hours and (d) average number of units in the system. Assuming customer order entry is online and instantaneous, explain if this system can meet an average flow time of 24 hours quoted to customers, i.e. "ships, on average, in 24 hours after order entry". 2. (10 points) Calculate the minimum number of servers would you need at Step 1 and at Step 2 to meet the peak demand of 12 units per day. Assuming each additional server corresponds to a one-time cost of 90,000$ / server, what would be the total incremental cost of the servers you add? II. Variability and Waiting Times Chapter 8 (25 Points): Consider a custom-order processing system consisting of two steps: In Step 1, we first assemble the product; then, in Step 2, we test and tune the product, before it is shipped to the customer. There is ample inventory storage allowed in the system. For each unit processed, on average, Step 1 takes 5.5 hours/unit and Step 2 takes 3.5 hours/unit. The standard deviation of unit processing times at each step is 7.7 hours. Currently there is a single server resource at each step. The system operates for 24 hours per day and 5 days per week. The current demand rate is 3 units/day and customer arrivals occur randomly according to a Poisson process with exponentially distributed interarrival times. The daily demand rate is expected to grow linearly in the future and then stabilize and stay flat; peak demand rate is estimated to be 12 units per day (arrivals are still Poisson for any demand rate). The duration of time with demand rate 12 units/day is expected to exceed 200 days. The unit cost of the product is 600$/unit. Current selling price is $1000/unit. Your goal is to maximize profit. 1. (15 points) For Step 1 and current demand rate = 3 units/day, estimate the (a) capacity in units per day. (b) utilization, (c) average flow time in hours and (d) average number of units in the system. Assuming customer order entry is online and instantaneous, explain if this system can meet an average flow time of 24 hours quoted to customers, i.e. "ships, on average, in 24 hours after order entry". 2. (10 points) Calculate the minimum number of servers would you need at Step 1 and at Step 2 to meet the peak demand of 12 units per day. Assuming each additional server corresponds to a one-time cost of 90,000$ / server, what would be the total incremental cost of the servers you add

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started