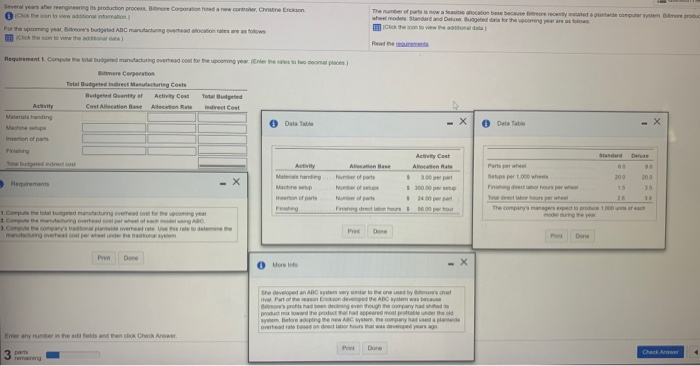

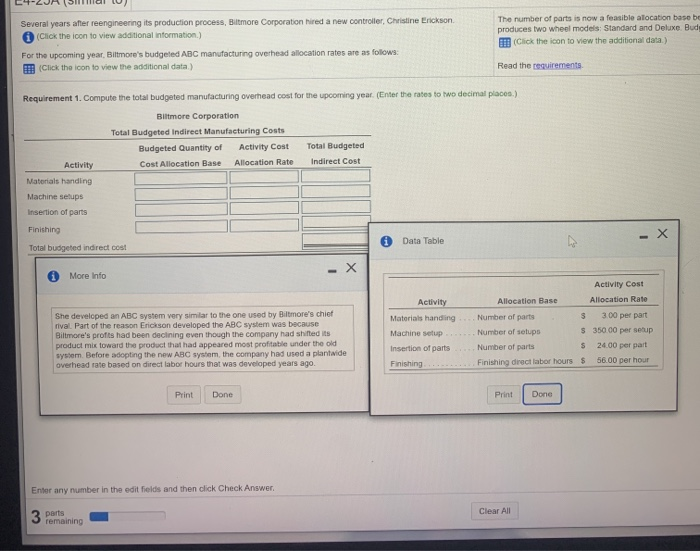

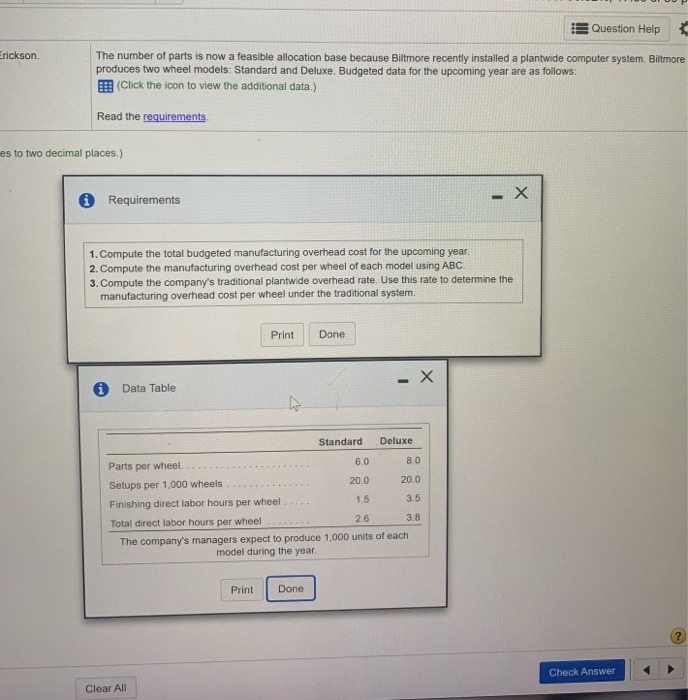

dan s un The number of parts is now a c tion be because Several years he reengineering proction process. Batore Corporation Contoon to view additional toon For the upcoming year 's budgeted ADC manucurgead de computers are produs Click the icon to view the data) to as are as follows: Requirement i Compute the low budgematachang overhead coat for the upcoming year termes de places Total Budgeted in Manc Budgeted Quantity of Cost Allocation Base ing Costs Activity Cout Allocation Rate o Budgeted Matera handing Data Table Data Table Total buspeted naract cont Number of parts Nuoro o rts ng Me handing Machine soup Inson of Fg F hours N or 600 g 1. Compute the total budgedachung v o 3. mehmang over w helofach mode the She developed and al Parthen very marathone by on deve the wymas tec 3 Check Aranet Several years after reengineering its production process, Biltmore Corporation Med a new controller, Christine Erickson (Click the icon to view additional information) The number of parts is now a feasible location baseb produces two wheel models: Standard and Deluxe Bud (Click the icon to view the additional data) For the upcoming year, Biltmore's budgeted ABC manufacturing overhead allocation rates are as follows: Click the icon to view the additional data) Read the requirements Requirement 1. Compute the total budgeted manufacturing overhead cost for the upcoming year (Enter the rates to wo decimal places) Biltmore Corporation Total Budgeted Indirect Manufacturing Costs Budgeted Quantity of Activity Cost Cost Allocation Base Allocation Rate Total Budgeted Indirect Cost Activity Material handing Machine setups Insertion of parts Finishing Total budgeted indirect cost Data Table 1 X - More Info Activity Cost Allocation Rate Activity Allocation Base Material handing Number of parts Machines Number of setups She developed an ABC system very similar to the one used by Biltmore's chief ival Part of the reason Erickson developed the ABC system was because Biltmore's profts had been declining even though the company had shifted its product mi toward the product that had appeared most profile under the old system Before dopting the new ABC Swam the company had used a plantide overhead rate based on direct labor hours that was developed years ago 3 300 per part $ 35000 per setup $ 2400 per part $ 56.00 per hour Insertion of parts Number of parts Finishing direct labor hours Finishing Print Done Print Dono Enter any number in the edit fields and then click Check Answer Serning Clear All 3 parts Question Help Erickson. The number of parts is now a feasible allocation base because Biltmore recently installed a plantwide computer system. Biltmore produces two wheel models: Standard and Deluxe. Budgeted data for the upcoming year are as follows: E (Click the icon to view the additional data.) Read the requirements es to two decimal places.) Requirements 1. Compute the total budgeted manufacturing overhead cost for the upcoming year 2. Compute the manufacturing overhead cost per Wheel of each model using ABC 3. Compute the company's traditional plantwide overhead rate. Use this rate to determine the manufacturing overhead cost per Wheel under the traditional system. Print Done - X Data Table Standard Deluxe Parts per wheel. 6.0 8.0 Setups per 1,000 wheels 20.0 20.0 Finishing direct labor hours per wheel..... 1.5 3,5 Total direct labor hours per wheel 3.8 The company's managers expect to produce 1,000 units of each model during the year 26 Print Done Check Answer Clear All dan s un The number of parts is now a c tion be because Several years he reengineering proction process. Batore Corporation Contoon to view additional toon For the upcoming year 's budgeted ADC manucurgead de computers are produs Click the icon to view the data) to as are as follows: Requirement i Compute the low budgematachang overhead coat for the upcoming year termes de places Total Budgeted in Manc Budgeted Quantity of Cost Allocation Base ing Costs Activity Cout Allocation Rate o Budgeted Matera handing Data Table Data Table Total buspeted naract cont Number of parts Nuoro o rts ng Me handing Machine soup Inson of Fg F hours N or 600 g 1. Compute the total budgedachung v o 3. mehmang over w helofach mode the She developed and al Parthen very marathone by on deve the wymas tec 3 Check Aranet Several years after reengineering its production process, Biltmore Corporation Med a new controller, Christine Erickson (Click the icon to view additional information) The number of parts is now a feasible location baseb produces two wheel models: Standard and Deluxe Bud (Click the icon to view the additional data) For the upcoming year, Biltmore's budgeted ABC manufacturing overhead allocation rates are as follows: Click the icon to view the additional data) Read the requirements Requirement 1. Compute the total budgeted manufacturing overhead cost for the upcoming year (Enter the rates to wo decimal places) Biltmore Corporation Total Budgeted Indirect Manufacturing Costs Budgeted Quantity of Activity Cost Cost Allocation Base Allocation Rate Total Budgeted Indirect Cost Activity Material handing Machine setups Insertion of parts Finishing Total budgeted indirect cost Data Table 1 X - More Info Activity Cost Allocation Rate Activity Allocation Base Material handing Number of parts Machines Number of setups She developed an ABC system very similar to the one used by Biltmore's chief ival Part of the reason Erickson developed the ABC system was because Biltmore's profts had been declining even though the company had shifted its product mi toward the product that had appeared most profile under the old system Before dopting the new ABC Swam the company had used a plantide overhead rate based on direct labor hours that was developed years ago 3 300 per part $ 35000 per setup $ 2400 per part $ 56.00 per hour Insertion of parts Number of parts Finishing direct labor hours Finishing Print Done Print Dono Enter any number in the edit fields and then click Check Answer Serning Clear All 3 parts Question Help Erickson. The number of parts is now a feasible allocation base because Biltmore recently installed a plantwide computer system. Biltmore produces two wheel models: Standard and Deluxe. Budgeted data for the upcoming year are as follows: E (Click the icon to view the additional data.) Read the requirements es to two decimal places.) Requirements 1. Compute the total budgeted manufacturing overhead cost for the upcoming year 2. Compute the manufacturing overhead cost per Wheel of each model using ABC 3. Compute the company's traditional plantwide overhead rate. Use this rate to determine the manufacturing overhead cost per Wheel under the traditional system. Print Done - X Data Table Standard Deluxe Parts per wheel. 6.0 8.0 Setups per 1,000 wheels 20.0 20.0 Finishing direct labor hours per wheel..... 1.5 3,5 Total direct labor hours per wheel 3.8 The company's managers expect to produce 1,000 units of each model during the year 26 Print Done Check Answer Clear All