Data 1 You work for Thunderduck Custom Tables Inc. This is the first month of operations. The company designs and manufactures specialty tables. Each table

| Data 1 | You work for Thunderduck Custom Tables Inc. This is the first month of operations. The company designs and manufactures specialty tables. Each table is specially customized for the customer. This month, you have been asked to develop and manufacture two new tables for customers. You will design and build the tables. The company does not have indirect materials. You will be keeping track of the costs incurred to manufacture the tables using Job #1 Cost Sheet and Job #2 Cost Sheet. | ||||

| The cost of the direct materials that can be used to manufacture the table are as follows. | |||||

| Table Top | $2,100 | ||||

| Table legs, quantity 4 ($700 per leg) | $2,800 | ||||

| Drawer | $410 | ||||

| Assume a $65 per hour wage rate to the assembly employees. | |||||

| The company uses a job order costing system and applies manufacturing overhead to jobs based on direct labor hours. | |||||

| The company estimates that there will be 120 direct labor hours worked during the month. | |||||

| The fixed estimated manufacturing overhead costs per month are: | |||||

| Factory supervisor salary | $3,300 | ||||

| Rent for the factory | $600 | ||||

| Depreciation of factory equipment | $900 | ||||

| Property insurance of factory | $1,800 | ||||

| ____________________ | |||||

| Total Estimated manufacturing overhead | $6,600 | ||||

| ------------------------------ | |||||

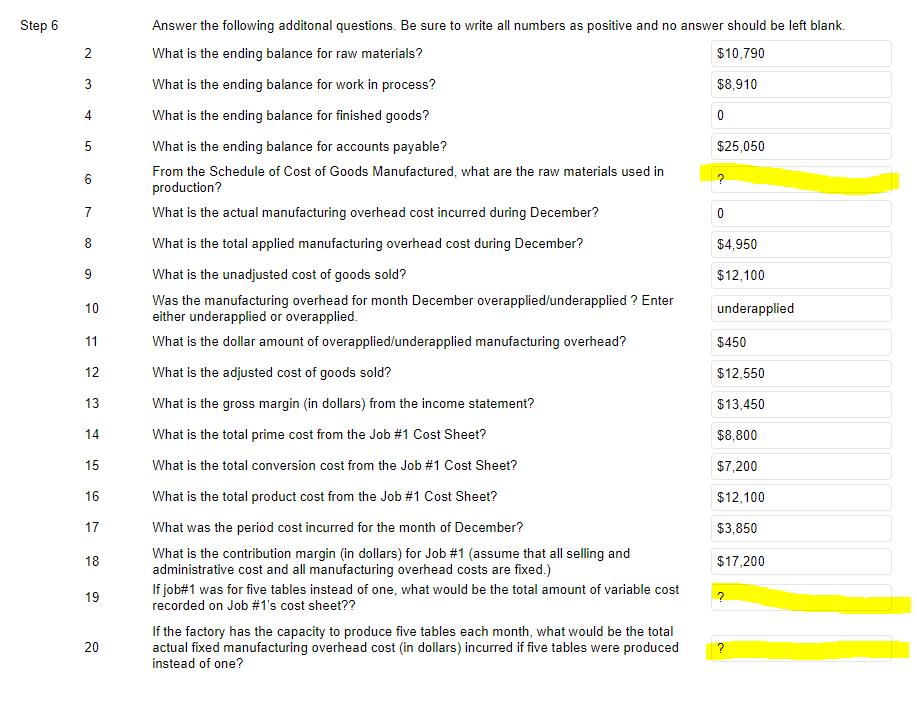

| 1 | What is the predetermined overhead rate (POHR)? | ?? | |||

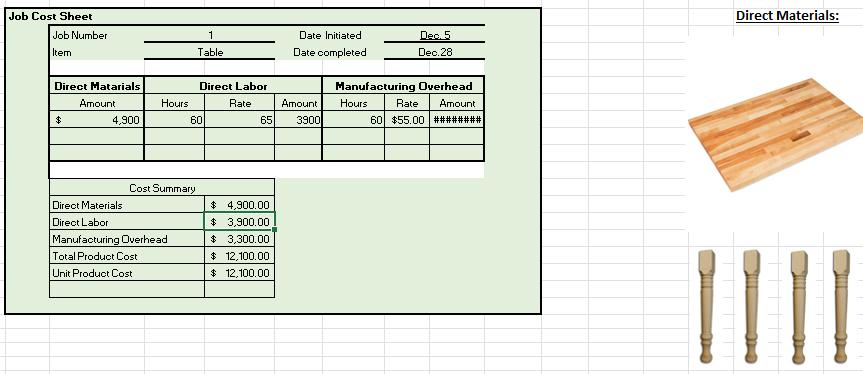

| Data 2 | The first order you received was to manufacture a table using a table top and four legs. This is your Job #1. | ||||

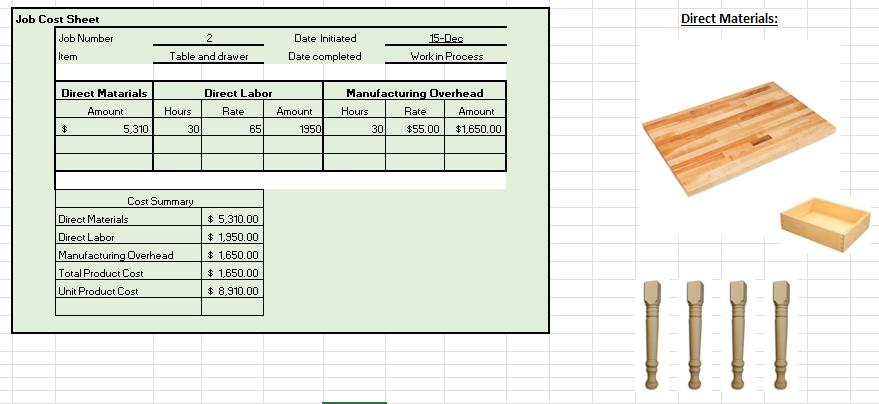

| Data 3 | The customer that has ordered Job #2, wants a table that is the same as Job #1, but wants to also add a drawer to the table. | ||||

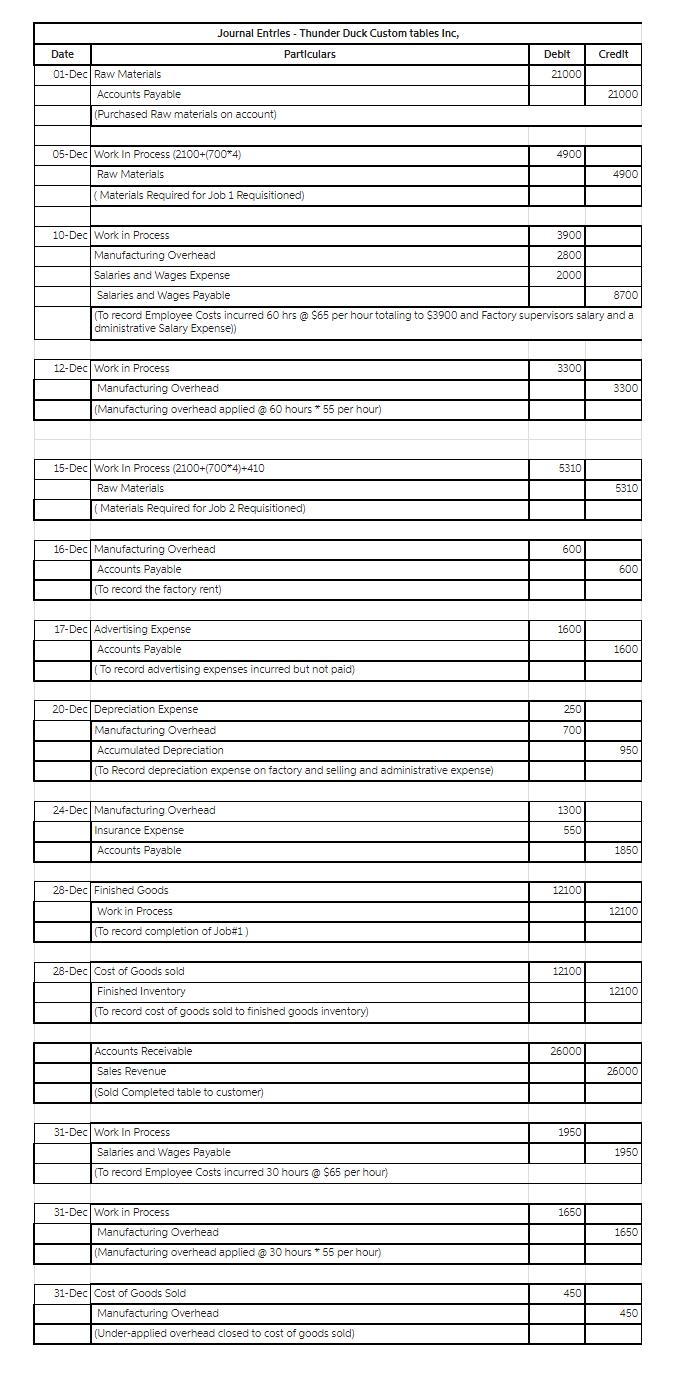

| Step 1 | The following is a list of transactions that need to be recorded for the company for activity in the month of December. Record those in the "General Journal" tab of the excel file using the proper format. Please use the following accounts: | ||||

| Accounts payable | Depreciation expense | Salaries and wages expense | |||

| Accounts receivables | Finished goods | Salaries and wages payable | |||

| Accumulated depreciation | Insurance expense | Sales revenue | |||

| Advertising expense | Manufacturing overhead | Work in process | |||

| Cost of goods sold | Raw materials | ||||

| 1-Dec | Raw materials purchased on account, $21,000. | ||||

| 5-Dec | All Raw materials needed for Job #1 were requested from the material storage for use during the month. All materials are direct. (After you journalize this entry please enter the information into Job #1 Cost Sheet) | ||||

| 10-Dec | The following employee costs were incurred but not paid during the month: | ||||

| Direct labor for Job #1, consisted of 60 hours at a rate of $65 per hour, totaling $3,900. (After you journalize this entry please enter the information into Job #1 Cost Sheet) | |||||

| Salary for supervisor of the factory $2,800. | |||||

| Administrative Salary $2,000. | |||||

| 12-Dec | Manufacturing overhead cost was applied based on direct labor hours to Job #1 using the POHR calculated in Question 1. (After you journalize this entry please enter the information into Job #1 Cost Sheet) | ||||

| 15-Dec | All Raw materials needed for Job #2 were requested from the material storage for use during the month. All materials are direct. (After you journalize this entry please enter the information into Job #2 Cost Sheet) | ||||

| 16-Dec | Rent for the month of December for the factory building incurred but not paid $600. | ||||

| 17-Dec | Advertising costs incurred but not paid for the month was $1,600. | ||||

| 20-Dec | Depreciation for the month of December was recorded on equipment $950 ($700 for equipment used in the factory and $250 for equipment used in selling and administrative activities). | ||||

| 24-Dec | Property insurance incurred but not paid $1,850 ($1,300 for the factory and $550 for selling and administrative offices). | ||||

| 28-Dec | Job #1 was completed and transferred to Finished Goods during the month. | ||||

| 28-Dec | The completed table was sold on account to the customer for $26,000 during the month. (Hint: Make sure to account for the cost of the table that was sold using the cost from the job cost sheet.) | ||||

| 31-Dec | By the end of the month, 30 hours of direct labor were incurred at a rate of $65 per hour, totaling $1,950 to begin production on job #2. The employees will be paid next month. (After you journalize this entry please enter the information into Job #2 Cost Sheet) | |||

| 31-Dec | Manufacturing overhead cost was applied using the direct labor hours from Job #2 and the POHR calculated in Question 1. (After you journalize this entry please enter the information into Job #2 Cost Sheet) | |||

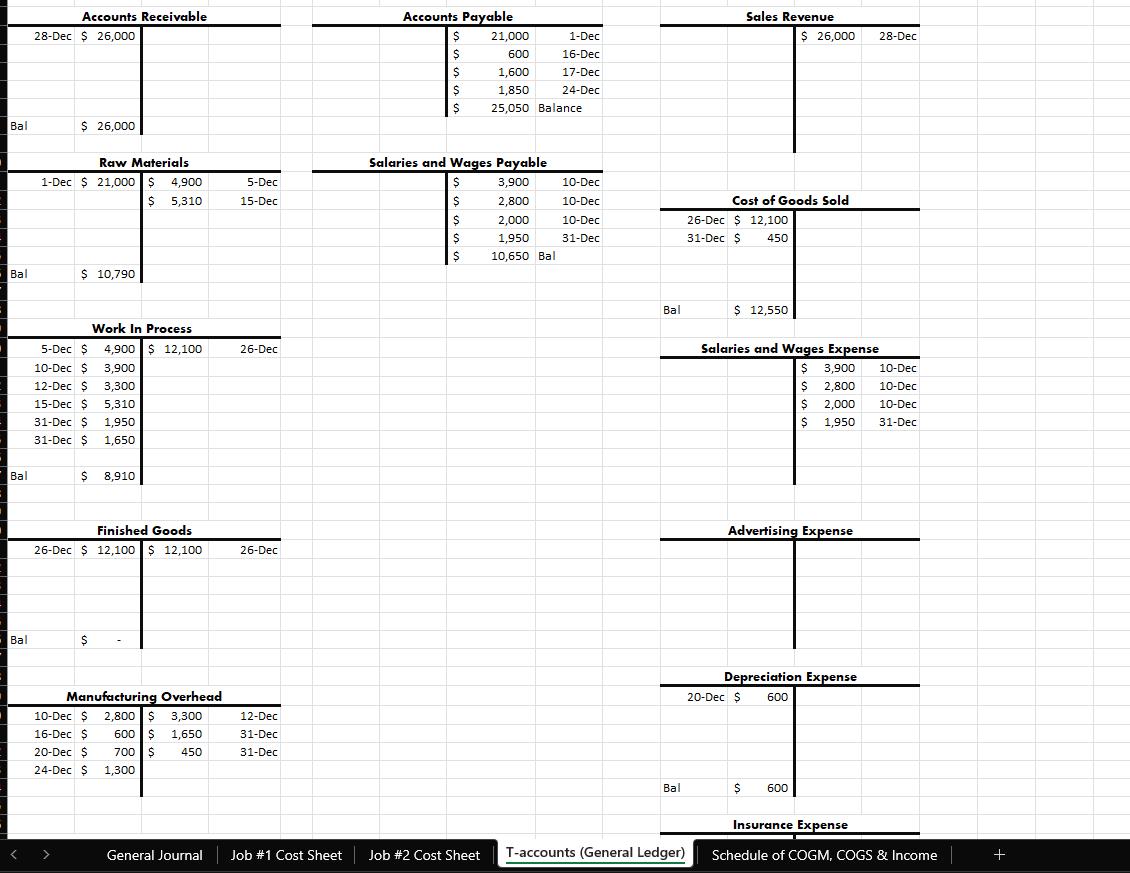

| Step 2 | Post the journal entries that you recorded on the “General Journal” tab to the “T-accounts (General Ledger)” tab and calculate the balance for each account. This is the company's first month of business, so there will not be any beginning balances. | |||

| 31-Dec | Record the entry in the general journal to close the Manufacturing Overhead account and adjust for overapplied/underapplied overhead. | |||

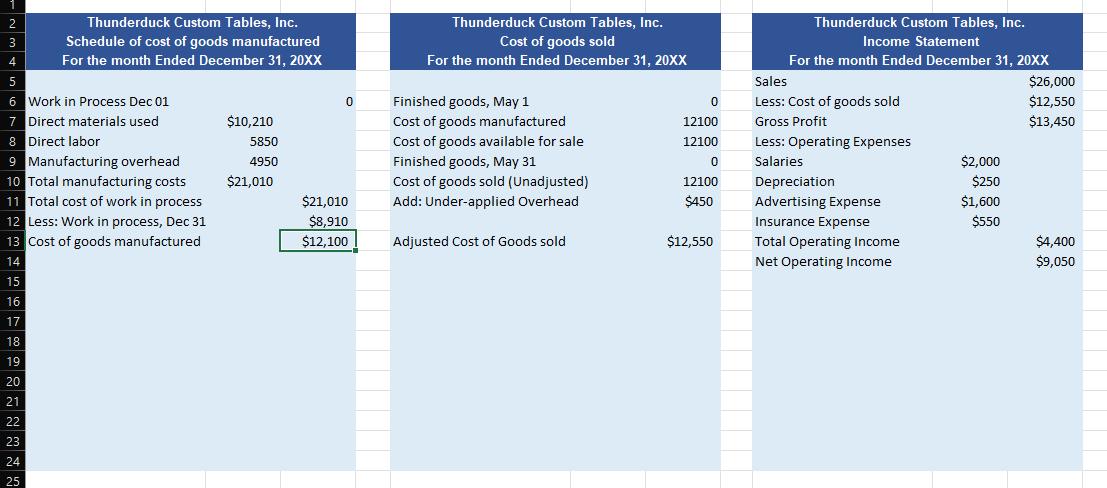

| Step 3 | Prepare a Schedule of Cost of Goods Manufactured and a Schedule of Cost of Goods Sold on the "Schedule of COGM and COGS" tab for Job #1 and Job #2 that were worked on during the month by the company. Make sure to follow the format noted in your book (pg. 109). (Hint: This is the company's first month of operations and therefore the beginning balances will be zero.) | |||

| Step 4 | Prepare an Income Statement for the month using the Traditional Format on the "Income Statement" tab. | |||

| Step 5 | Use the following check figures and make any necessary corrections. | |||

| Check Figure 1: Cost of Goods Manufactured $12,100 | ||||

| Check Figure 2: Net Operating Income $9,050 | ||||

Date 01-Dec Raw Materials Accounts Payable (Purchased Raw materials on account) 05-Dec Work In Process (2100+(700*4) Raw Materials (Materials Required for Job 1 Requisitioned) 10-Dec Work in Process Manufacturing Overhead Salaries and Wages Expense Salaries and Wages Payable 12-Dec Work in Process Journal Entries - Thunder Duck Custom tables Inc, Particulars Manufacturing Overhead (Manufacturing overhead applied @ 60 hours * 55 per hour) 15-Dec Work In Process (2100+(700*4)+410 Raw Materials Materials Required for Job 2 Requisitioned) 16-Dec Manufacturing Overhead Accounts Payable (To record the factory rent) 17-Dec Advertising Expense Accounts Payable (To record advertising expenses incurred but not paid) 20-Dec Depreciation Expense 8700 (To record Employee Costs incurred 60 hrs @ $65 per hour totaling to $3900 and Factory supervisors salary and a dministrative Salary Expense)) Manufacturing Overhead Accumulated Depreciation (To Record depreciation expense on factory and selling and administrative expense) 24-Dec Manufacturing Overhead Insurance Expense Accounts Payable 28-Decl Finished Goods Work in Process (To record completion of Job#1 28-Dec Cost of Goods sold Finished Inventory (To record cost of goods sold to finished goods inventory) Accounts Receivable Sales Revenue (Sold Completed table to customer) 31-Dec Work In Process Salaries and Wages Payable (To record Employee Costs incurred 30 hours @ $65 per hour) 31-Dec Work in Process Manufacturing Overhead (Manufacturing overhead applied @ 30 hours *55 per hour) 31-Dec Cost of Goods Sold Debit Manufacturing Overhead (Under-applied overhead closed to cost of goods sold) 21000 4900 3900 2800 2000 3300 5310 600 1600 250 700 1300 550 12100 12100 26000 1950 1650 Credit 450 21000 4900 3300 5310 600 1600 950 1850 12100 12100 26000 1950 1650 450

Step by Step Solution

3.50 Rating (157 Votes )

There are 3 Steps involved in it

Step: 1

Predetermined manufacturing overhead rate Total estimated manufacturing overhead Total direct labor ...

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started