Question

: Develop a causal network for each of these three risk events based on the FMEA worksheet provided to you by your boss and all

: Develop a causal network for each of these three risk events based on the FMEA worksheet provided to you by your boss and all your other technical/engineering knowledge, as response to the 2nd Question in the 1 + 6 General guiding questions in risk management. Use your knowledge of the various Rules of Causations in developing a rich causal network.

From this causal network, you recognized the importance of detecting the hazards contributing to the occurrence of these risk events, controlling these risk events as soon as they start, and manage any consequences (4th in the 1 + 6 General guiding questions in risk management). Furthermore, you recalled the various mitigation strategies as summarized in the Risk Mitigation Map/Tree in your ENMA 424 class.

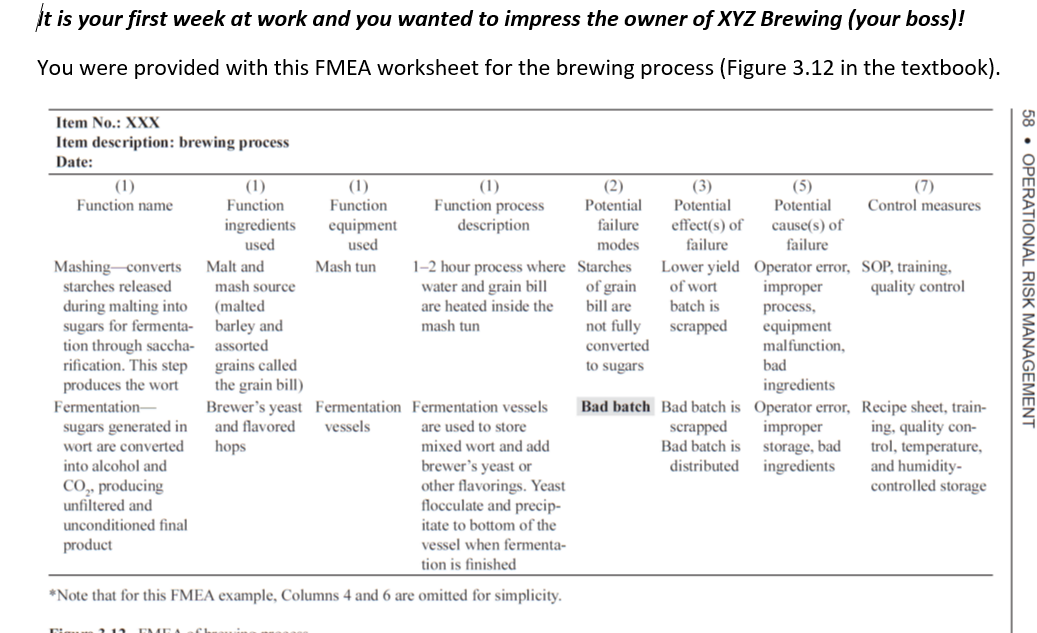

It is your first week at work and you wanted to impress the owner of XYZ Brewing (your boss)! You were provided with this FMEA worksheet for the brewing process (Figure 3.12 in the textbook). Item No.: XXX Item description: brewing process Date: (1) (1) (1) (1) (2) (3) (5) (7) Function name Function Function Function process Potential Potential Potential Control measures ingredients equipment description failure effect(s) of cause(s) of used used modes failure failure Mashing-converts Malt and Mash tun 1-2 hour process where Starches Lower yield Operator error, SOP, training, starches released mash source water and grain bill of wort improper quality control during malting into (malted are heated inside the batch is process, sugars for fermenta- barley and mash tun not fully scrapped equipment tion through saccha- assorted converted malfunction, rification. This step grains called to sugars bad produces the wort the grain bill) ingredients Fermentation- Brewer's yeast Fermentation Fermentation vessels Bad batch Bad batch is Operator error, Recipe sheet, train- sugars generated in and flavored vessels are used to store scrapped improper ing, quality con- wort are converted hops mixed wort and add Bad batch is storage, bad trol, temperature, into alcohol and brewer's yeast or distributed ingredients and humidity- CO, producing other flavorings. Yeast controlled storage unfiltered and flocculate and precip- unconditioned final itate to bottom of the product vessel when fermenta- tion is finished *Note that for this FMEA example, Columns 4 and 6 are omitted for simplicity. 58. OPERATIONAL RISK MANAGEMENT of grain bill areStep by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started