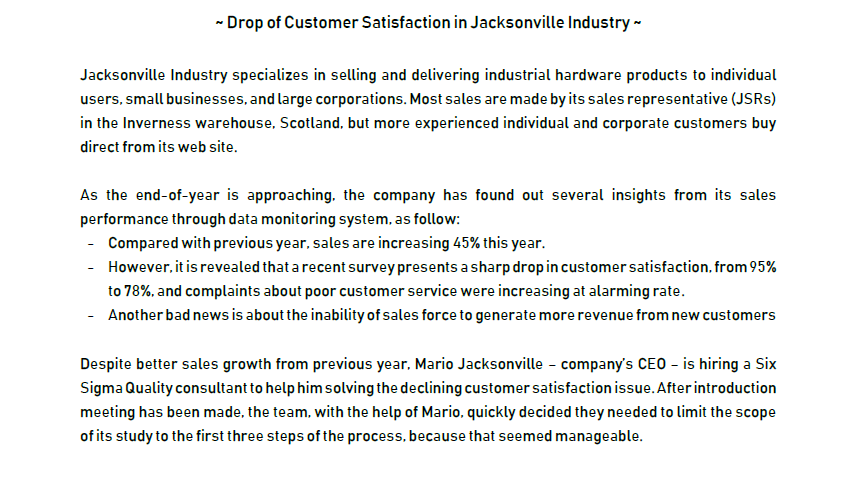

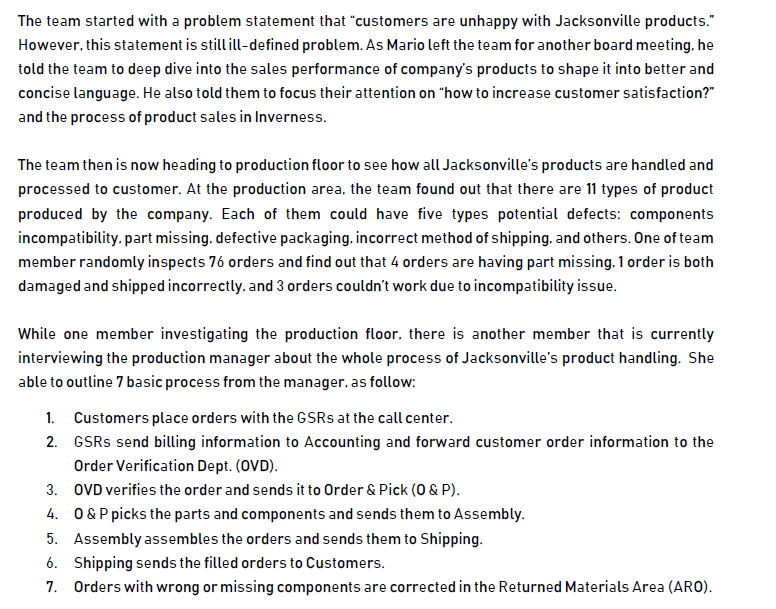

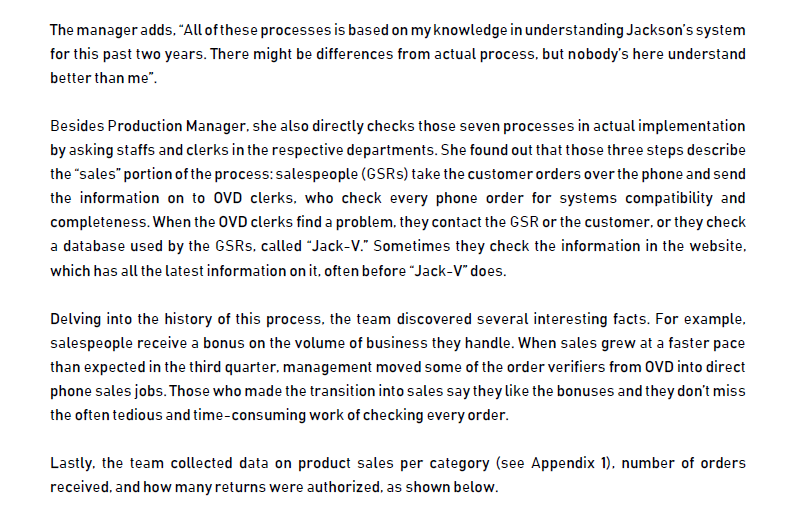

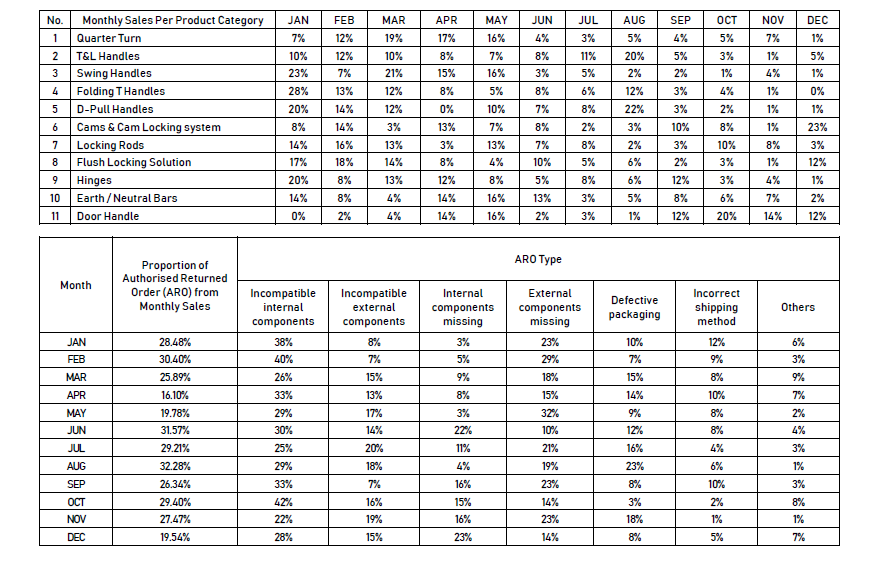

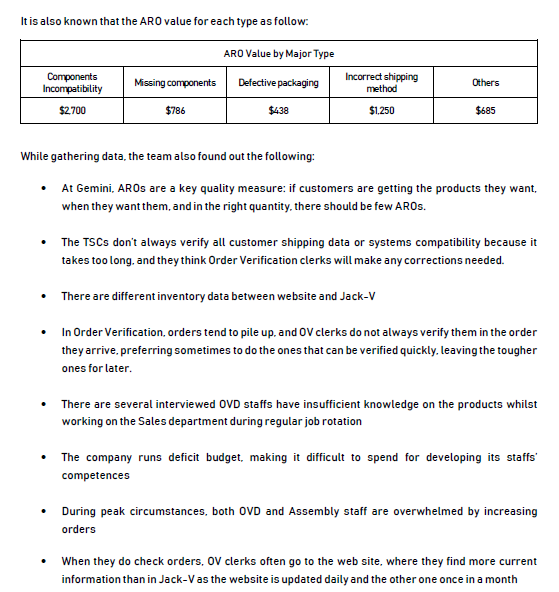

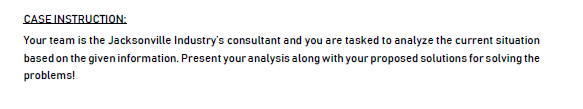

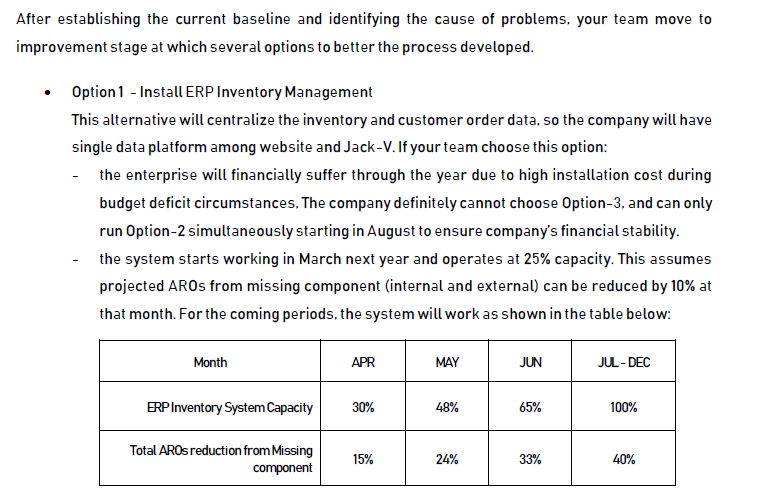

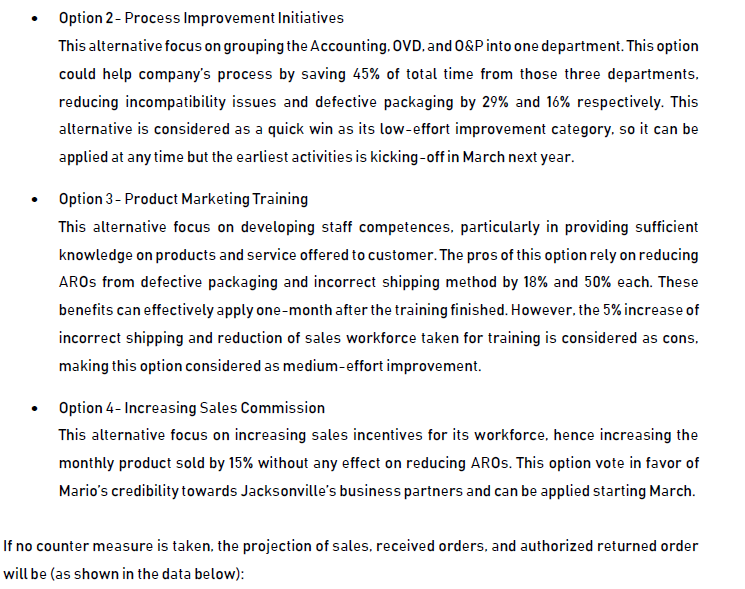

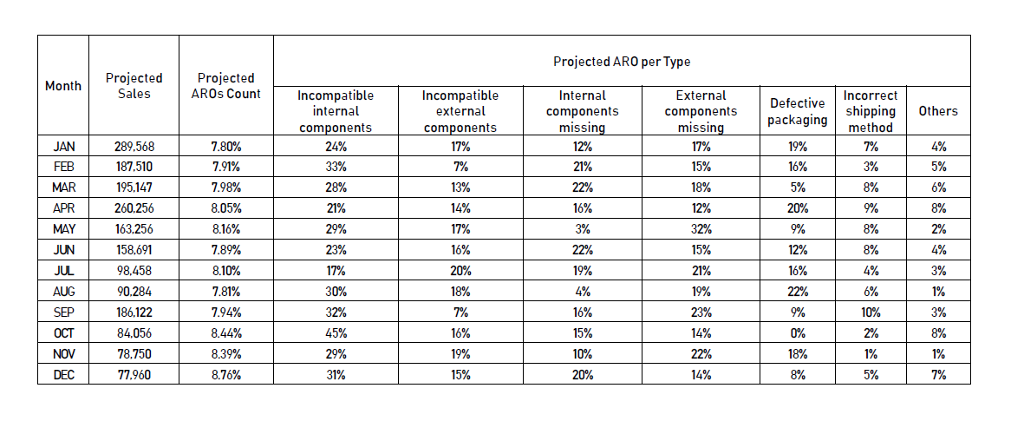

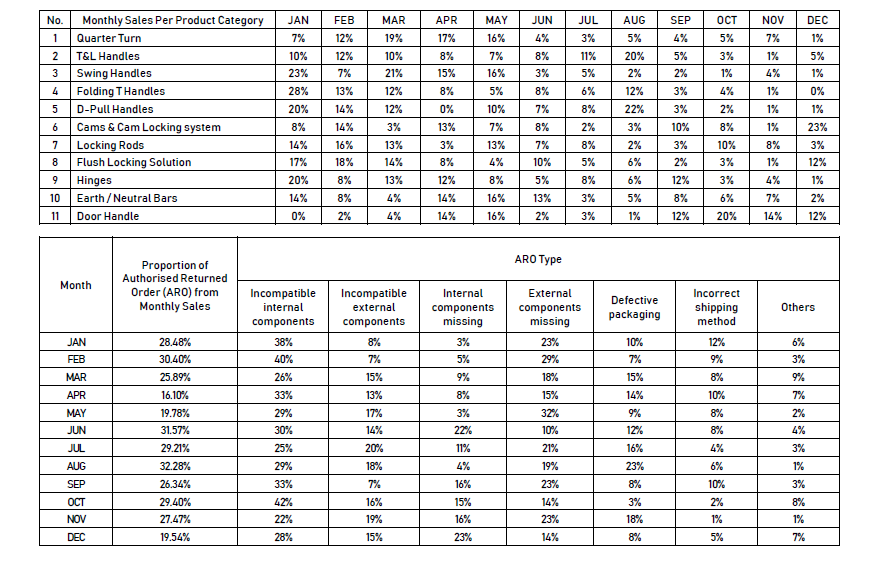

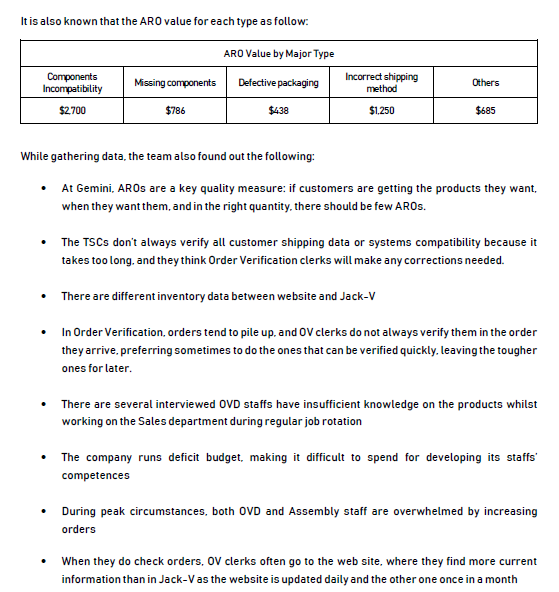

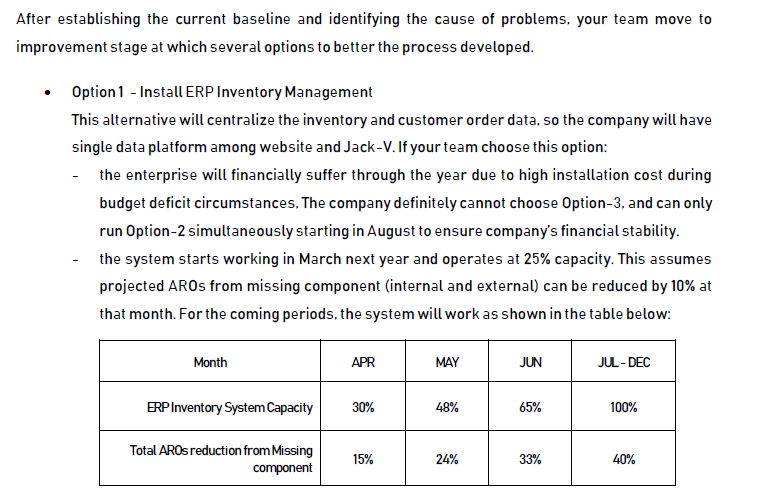

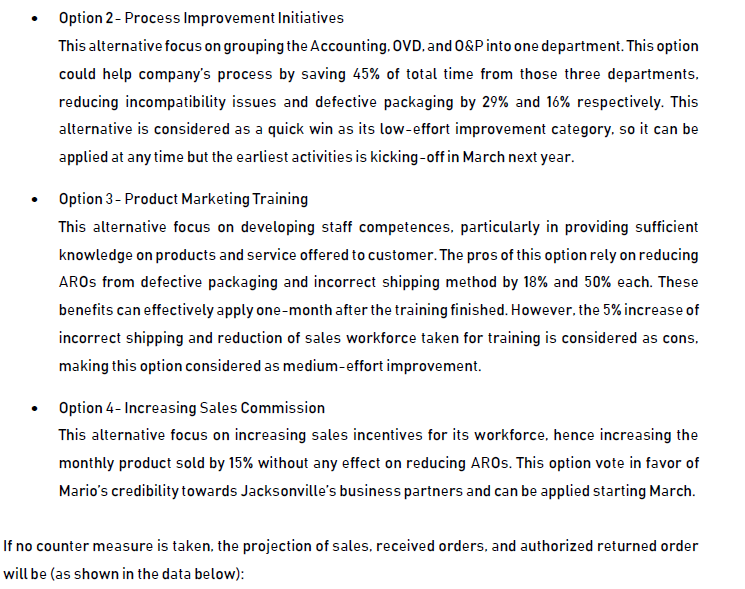

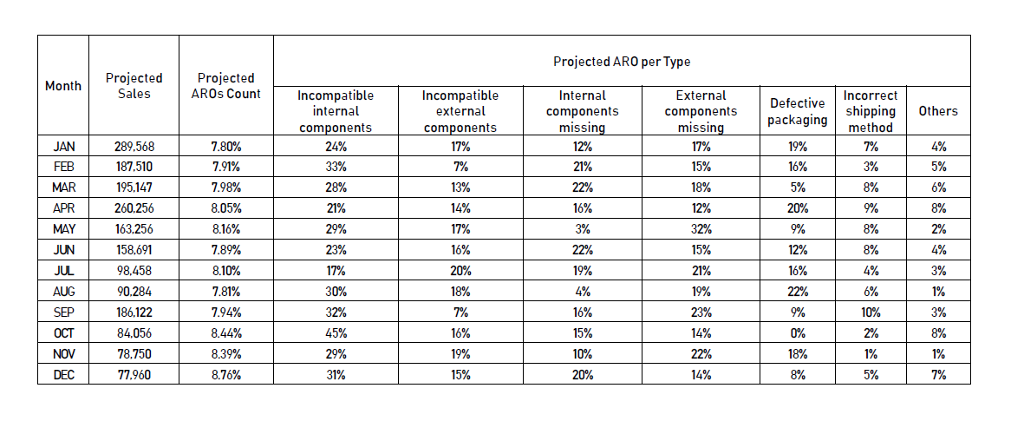

Drop of Customer Satisfaction in Jacksonville Industry Jacksonville Industry specializes in selling and delivering industrial hardware products to individual users, small businesses, and large corporations. Most sales are made by its sales representative (JSRs) in the Inverness warehouse, Scotland. but more experienced individual and corporate customers buy direct from its web site. As the end-of-year is approaching. the company has found out several insights from its sales performance through data monitoring system. as follow: -Compared wlth previous year, sales are increasing 45% this year. -However, it is revealed thatare cent survey presents a sharp drop in customersatisfaction, from 95% to 78%, and complaints about poor customer service were increasing at alarming rate Another bad news is about the inability of sales force to generate more revenue from new customers - Despite better sales growth from previous year. Mario Jacksonville company's CEO - is hiring a Six Sigma Quality consultant to help him solving the declining customer satisfaction issue. After introduction meeting has been made, the team, with the help of Mario. quickly decided they needed to limit the scope ofits study to the first three steps of the process. because that seemed manageable. The team started with a problem statement that "customers are unhappy with Jacksonville products However. this statement is stillill-defined problem. As Mario left the team for another board meeting. he told the team to deep dive into the sales performance of company's products to shape it into better and concise language. He also told them to focus their attention on "how to increase customer satisfaction?" and the process of product sales in Inverness The team then is now heading to production floor to see how all Jacksonville's products are handled and processed to customer. At the production area, the team found out that there are 11 types of product produced by the company. Each of them could have five types potential defects: components incompatibility, part missing, defective packaging. incorrect method of shipping, and others. One of team member randomly inspects 76 orders and find out that 4 orders are having part missing. 1 order is both damaged and shipped incorrectly. and 3 orders couldn't work due to incompatibility issue While one member investigating the production floor. there is another member that is currently interviewing the production manager about the whole process of Jacksonville's product handling. She able to outline 7 basic process from the manager. as follow: Customers place orders with the GSRs at the call center GSRs send billing information to Accounting and forward customer order information to the Order Verification Dept. (OVD). OVD verifies the order and sends it to Order & Pick (O & P) 0 & P picks the parts and components and sends them to Assembly Assembly assembles the orders and sends them to Shipping Shipping sends the filled orders to Customers Orders with wrong or missing components are corrected in the Returned Materials Area (ARO) 1. 2. 3. 4. 5. 6. 7. The manager adds. All ofthese processes is based on my knowledge in understanding Jackson's system for this past two years. There might be differences from actual process, but nobody's here understand better than me". Besides Production Manager. she also directly checks those seven processes in actual implementation by asking staffs and clerks in the respective departments. She found out that those three steps describe the "sales" portion of the process: salespeople (GSRs) take the customer orders over the phone and send the information on to OVD clerks, who check every phone order for systems compatibility and completeness. When the OVD clerks find a problem, they contact the GSR or the customer. or they check a database used by the GSRs. called "Jack-V." Sometimes they check the information in the website which has all the latest information on it, often before "Jack-V" does. Delving into the history of this process. the team discovered several interesting facts. For example. salespeople receive a bonus on the volume of business they handle. When sales grew at a faster pace than expected in the third quarter. management moved some of the order verifiers from OVD into direct phone sales jobs.Those who made the transition into sales say they like the bonuses and they don't miss the often tedious and time-consuming work of checking every order. Lastly. the team collected data on product sales per category (see Appendix 1. number of orders received. and how many returns were authorized. as shown below. MAR 19% 10% 21% 12% 12% APR 17% No.Monthly Sales Per Product Category JAN FEB MAY I JUN JUL AUG SEP | 0CT | NOV | DEC 1 Quarter Turn 2 TGL Handles 3 Swing Handles 4 Folding THandles 5 D-Pull Handles 6 Cams & Cam Locking system 7 Locking Rods 8 Flush Locking Solution 10% 4% 10% 23% 28% 20% 8% 20% 12% 22% 8% 6% 1% 14% 14% 16% 18% 0% 10% 2% 13% 8% 10% 1% 8% 23% 14% 17% 20% 14% 13% 14% 13% 13% 4% 8% 10% 10% 12% 9 Hinges 10 Earth/Neutral Bars 14% 14% Door Handle 16% 20% | 14% | 12% ARO Type Proportion of Authorised Returned Month Order (AR0) fromIncompatible Incompatible Internal components missing External components missing Defective packaging Incorrect shipping method Monthly Sales internal components Others external components 28.48% 30.40% 25.89% 16.10% 19.78% 31.57% 29.21% 26% 15% 14% MAR 33% MAY 32% 2% 14% 16% 4% 263 9.40% 27.47% 19.54% 33% 16% 15% 16% 42% 16% 14% DEC 14% It is also known that the ARO value for each type as follow ARO Value by Major Type Components Incompatibility g componentsDefective packaging Incorrect shipping method Others $2700 $786 $438 $1,250 $685 While gathering data, the team also found out the following: At Gemini, AROs are a key quality measure: if customers are getting the products they want, when they want them, and in the right quantity. there should be few AROs. The TSCs don't always verify all customer shipping data or systems compatibility because it takes toolong. and they think Order Verification clerks will make any corrections needed. . There are different inventory data between website and Jack-V In Order Verification, orders tend to pile up. and OV clerks do not always verify them in the order they arrive. preferring sometimes to do the ones that can be verified quickly. leaving the tougher ones for later, There are several interviewed OVD staffs have insufficient knowledge on the products whilst working on the Sales department during regular job rotation The company runs deficit budget, making it difficult to spend for developing its staffs' competences .During peak circumstances, both OVD and Assembly staff are overwhelmed by increasing orders When they do check orders, OV clerks often go to the web site, where they find more current information than in Jack-Vas the website is updated daily and the other one once in a month Your team is the Jacksonville Industry's consultant and you are tasked to analyze the current situation based on the given information. Presentyour analysis along with your proposed solutions for solving the problems! After establishing the current baseline and identifying the cause of problems, your team move to improvement stage at which several options to better the process developed. Option 1 InstallERP Inventory Management This alternative will centralize the inventory and customer order data, so the company will have single data platform among website and Jack-V. If your team choose this option: the enterprise will financially suffer through the year due to high installation cost during budget deficit circumstances. The company definitely cannot choose Option-3. and can only run Option-2 simultaneously starting in August to ensure company's financial stability. the system starts working in March next year and operates at 25% capacity. This assumes projected AROs from missing component (internal and external) can be reduced by 10% at that month. For the coming periods, the system will work as shown in the table below: Month MAY UIN JUL-DEC ERP Inventory SystemCapacity| 30% 48% 65% Total AROsreduction from Missing component 15% 24% 33% Option 2- Process Improvement Initiatives This alternative focus on grouping the Accounting. OVD,and 0&P into one department. This option could help company's process by saving 45% of total time from those three departments. reducing incompatibility issues and defective packaging by 29% and 16% respectively. This alternative is considered as a quick win as its low-effort improvement category. so it can be applied at anytime but the earliest activities is kicking-off in March next year Option 3- Product Marketing Training This lernative focus on developing staff competences. particularly in providing sufficient knowledge on products and service offered to customer. The pros of this option rely on reducing AROs from defective packaging and incorrect shipping method by 18% and 50% each. These benefits can effectively apply one-month after the training finished. However, the 5% increase of incorrect shipping and reduction of sales workforce taken for training is considered as cons. making this option considered as medium-effort improvement Option 4-Increasing Sales Commission This alternative focus on increasing sales incentives for its workforce, hence increasing the monthly product sold by 15% without any effect on reducing AROs. This option vote in favor of Mario's credibility towards Jacksonville's business partners and can be applied starting March. If no counter measure is taken. the projection of sales, received orders, and authorized returned order will be (as shown in the data below): Projected ARO per Type Projected Sales Projected AROs Count Month Incompatible internal components 24% Incompatible external components Internal components missin 12% External components missin Incorrect Defective shipping Others packaging method 289.568 187.510 195.147 260.256 7.80% 7.91% 98% 8.05% 816% 4% 5% 6% 15% 18% 16% 5% 13% 14% MAR 28% 8% 16% MAY 158.691 98,458 90.284 186.122 84,056 78.750 77.960 16% 20% 18% 15% 4% 8.10% 7.81% 94% 8.41% 8.39% 8.76% 4% 6% 10% 2% 16% AUG 0% 4% 16% 15% SEP 45% 16% 0% 8% 18% DEC 15% Drop of Customer Satisfaction in Jacksonville Industry Jacksonville Industry specializes in selling and delivering industrial hardware products to individual users, small businesses, and large corporations. Most sales are made by its sales representative (JSRs) in the Inverness warehouse, Scotland. but more experienced individual and corporate customers buy direct from its web site. As the end-of-year is approaching. the company has found out several insights from its sales performance through data monitoring system. as follow: -Compared wlth previous year, sales are increasing 45% this year. -However, it is revealed thatare cent survey presents a sharp drop in customersatisfaction, from 95% to 78%, and complaints about poor customer service were increasing at alarming rate Another bad news is about the inability of sales force to generate more revenue from new customers - Despite better sales growth from previous year. Mario Jacksonville company's CEO - is hiring a Six Sigma Quality consultant to help him solving the declining customer satisfaction issue. After introduction meeting has been made, the team, with the help of Mario. quickly decided they needed to limit the scope ofits study to the first three steps of the process. because that seemed manageable. The team started with a problem statement that "customers are unhappy with Jacksonville products However. this statement is stillill-defined problem. As Mario left the team for another board meeting. he told the team to deep dive into the sales performance of company's products to shape it into better and concise language. He also told them to focus their attention on "how to increase customer satisfaction?" and the process of product sales in Inverness The team then is now heading to production floor to see how all Jacksonville's products are handled and processed to customer. At the production area, the team found out that there are 11 types of product produced by the company. Each of them could have five types potential defects: components incompatibility, part missing, defective packaging. incorrect method of shipping, and others. One of team member randomly inspects 76 orders and find out that 4 orders are having part missing. 1 order is both damaged and shipped incorrectly. and 3 orders couldn't work due to incompatibility issue While one member investigating the production floor. there is another member that is currently interviewing the production manager about the whole process of Jacksonville's product handling. She able to outline 7 basic process from the manager. as follow: Customers place orders with the GSRs at the call center GSRs send billing information to Accounting and forward customer order information to the Order Verification Dept. (OVD). OVD verifies the order and sends it to Order & Pick (O & P) 0 & P picks the parts and components and sends them to Assembly Assembly assembles the orders and sends them to Shipping Shipping sends the filled orders to Customers Orders with wrong or missing components are corrected in the Returned Materials Area (ARO) 1. 2. 3. 4. 5. 6. 7. The manager adds. All ofthese processes is based on my knowledge in understanding Jackson's system for this past two years. There might be differences from actual process, but nobody's here understand better than me". Besides Production Manager. she also directly checks those seven processes in actual implementation by asking staffs and clerks in the respective departments. She found out that those three steps describe the "sales" portion of the process: salespeople (GSRs) take the customer orders over the phone and send the information on to OVD clerks, who check every phone order for systems compatibility and completeness. When the OVD clerks find a problem, they contact the GSR or the customer. or they check a database used by the GSRs. called "Jack-V." Sometimes they check the information in the website which has all the latest information on it, often before "Jack-V" does. Delving into the history of this process. the team discovered several interesting facts. For example. salespeople receive a bonus on the volume of business they handle. When sales grew at a faster pace than expected in the third quarter. management moved some of the order verifiers from OVD into direct phone sales jobs.Those who made the transition into sales say they like the bonuses and they don't miss the often tedious and time-consuming work of checking every order. Lastly. the team collected data on product sales per category (see Appendix 1. number of orders received. and how many returns were authorized. as shown below. MAR 19% 10% 21% 12% 12% APR 17% No.Monthly Sales Per Product Category JAN FEB MAY I JUN JUL AUG SEP | 0CT | NOV | DEC 1 Quarter Turn 2 TGL Handles 3 Swing Handles 4 Folding THandles 5 D-Pull Handles 6 Cams & Cam Locking system 7 Locking Rods 8 Flush Locking Solution 10% 4% 10% 23% 28% 20% 8% 20% 12% 22% 8% 6% 1% 14% 14% 16% 18% 0% 10% 2% 13% 8% 10% 1% 8% 23% 14% 17% 20% 14% 13% 14% 13% 13% 4% 8% 10% 10% 12% 9 Hinges 10 Earth/Neutral Bars 14% 14% Door Handle 16% 20% | 14% | 12% ARO Type Proportion of Authorised Returned Month Order (AR0) fromIncompatible Incompatible Internal components missing External components missing Defective packaging Incorrect shipping method Monthly Sales internal components Others external components 28.48% 30.40% 25.89% 16.10% 19.78% 31.57% 29.21% 26% 15% 14% MAR 33% MAY 32% 2% 14% 16% 4% 263 9.40% 27.47% 19.54% 33% 16% 15% 16% 42% 16% 14% DEC 14% It is also known that the ARO value for each type as follow ARO Value by Major Type Components Incompatibility g componentsDefective packaging Incorrect shipping method Others $2700 $786 $438 $1,250 $685 While gathering data, the team also found out the following: At Gemini, AROs are a key quality measure: if customers are getting the products they want, when they want them, and in the right quantity. there should be few AROs. The TSCs don't always verify all customer shipping data or systems compatibility because it takes toolong. and they think Order Verification clerks will make any corrections needed. . There are different inventory data between website and Jack-V In Order Verification, orders tend to pile up. and OV clerks do not always verify them in the order they arrive. preferring sometimes to do the ones that can be verified quickly. leaving the tougher ones for later, There are several interviewed OVD staffs have insufficient knowledge on the products whilst working on the Sales department during regular job rotation The company runs deficit budget, making it difficult to spend for developing its staffs' competences .During peak circumstances, both OVD and Assembly staff are overwhelmed by increasing orders When they do check orders, OV clerks often go to the web site, where they find more current information than in Jack-Vas the website is updated daily and the other one once in a month Your team is the Jacksonville Industry's consultant and you are tasked to analyze the current situation based on the given information. Presentyour analysis along with your proposed solutions for solving the problems! After establishing the current baseline and identifying the cause of problems, your team move to improvement stage at which several options to better the process developed. Option 1 InstallERP Inventory Management This alternative will centralize the inventory and customer order data, so the company will have single data platform among website and Jack-V. If your team choose this option: the enterprise will financially suffer through the year due to high installation cost during budget deficit circumstances. The company definitely cannot choose Option-3. and can only run Option-2 simultaneously starting in August to ensure company's financial stability. the system starts working in March next year and operates at 25% capacity. This assumes projected AROs from missing component (internal and external) can be reduced by 10% at that month. For the coming periods, the system will work as shown in the table below: Month MAY UIN JUL-DEC ERP Inventory SystemCapacity| 30% 48% 65% Total AROsreduction from Missing component 15% 24% 33% Option 2- Process Improvement Initiatives This alternative focus on grouping the Accounting. OVD,and 0&P into one department. This option could help company's process by saving 45% of total time from those three departments. reducing incompatibility issues and defective packaging by 29% and 16% respectively. This alternative is considered as a quick win as its low-effort improvement category. so it can be applied at anytime but the earliest activities is kicking-off in March next year Option 3- Product Marketing Training This lernative focus on developing staff competences. particularly in providing sufficient knowledge on products and service offered to customer. The pros of this option rely on reducing AROs from defective packaging and incorrect shipping method by 18% and 50% each. These benefits can effectively apply one-month after the training finished. However, the 5% increase of incorrect shipping and reduction of sales workforce taken for training is considered as cons. making this option considered as medium-effort improvement Option 4-Increasing Sales Commission This alternative focus on increasing sales incentives for its workforce, hence increasing the monthly product sold by 15% without any effect on reducing AROs. This option vote in favor of Mario's credibility towards Jacksonville's business partners and can be applied starting March. If no counter measure is taken. the projection of sales, received orders, and authorized returned order will be (as shown in the data below): Projected ARO per Type Projected Sales Projected AROs Count Month Incompatible internal components 24% Incompatible external components Internal components missin 12% External components missin Incorrect Defective shipping Others packaging method 289.568 187.510 195.147 260.256 7.80% 7.91% 98% 8.05% 816% 4% 5% 6% 15% 18% 16% 5% 13% 14% MAR 28% 8% 16% MAY 158.691 98,458 90.284 186.122 84,056 78.750 77.960 16% 20% 18% 15% 4% 8.10% 7.81% 94% 8.41% 8.39% 8.76% 4% 6% 10% 2% 16% AUG 0% 4% 16% 15% SEP 45% 16% 0% 8% 18% DEC 15%