Question

Embassy Motorcycles (EM) manufactures two lightweight motorcycles designed for easy handling and safety. The EZ-Rider model has a new engine and a low profile that

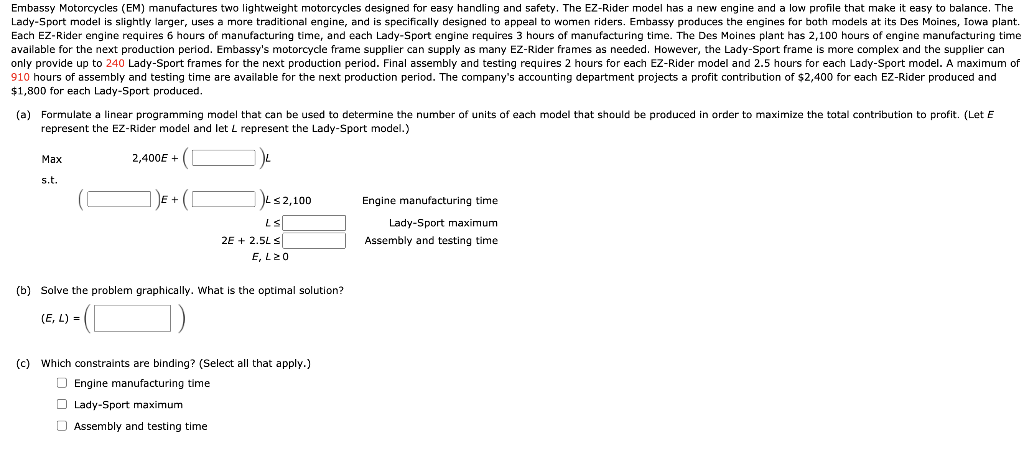

Embassy Motorcycles (EM) manufactures two lightweight motorcycles designed for easy handling and safety. The EZ-Rider model has a new engine and a low profile that make it easy to balance. The Lady-Sport model is slightly larger, uses a more traditional engine, and is specifically designed to appeal to women riders. Embassy produces the engines for both models at its Des Moines, Iowa plant. Each EZ-Rider engine requires 6 hours of manufacturing time, and each Lady-Sport engine requires 3 hours of manufacturing time. The Des Moines plant has 2,100 hours of engine manufacturing time available for the next production period. Embassy's motorcycle frame supplier can supply as many EZ-Rider frames as needed. However, the Lady-Sport frame is more complex and the supplier can only provide up to 240 Lady-Sport frames for the next production period. Final assembly and testing requires 2 hours for each EZ-Rider model and 2.5 hours for each Lady-Sport model. A maximum of 910 hours of assembly and testing time are available for the next production period. The company's accounting department projects a profit contribution of $2,400 for each EZ-Rider produced and $1,800 for each Lady-Sport produced.

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started