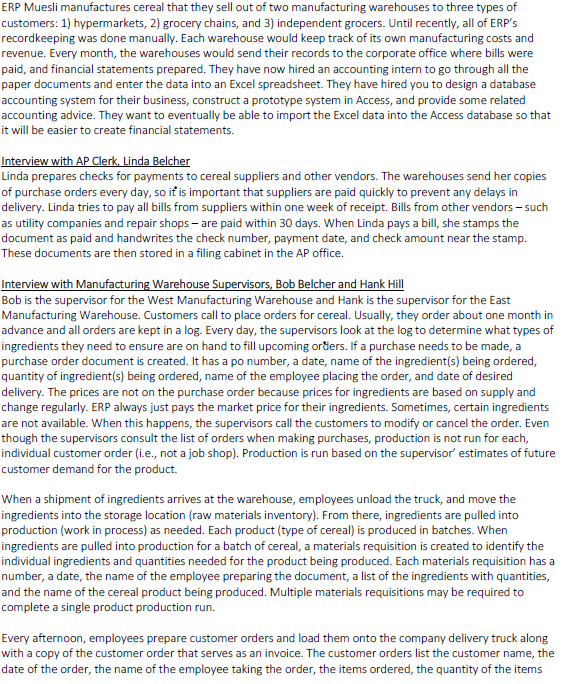

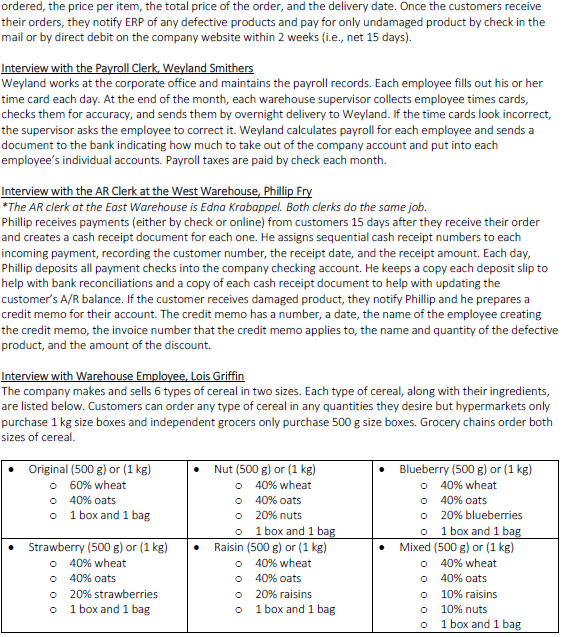

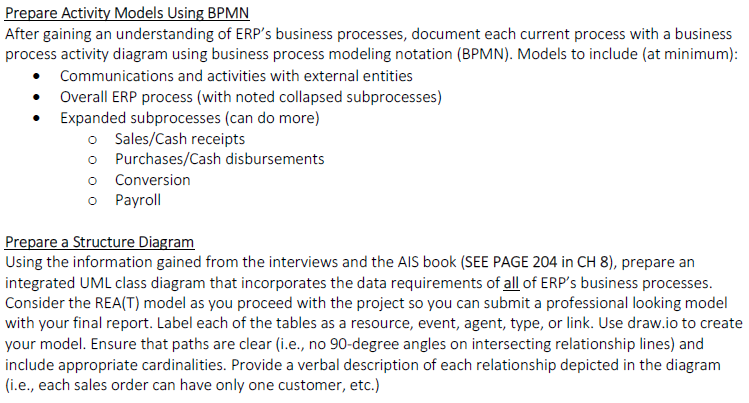

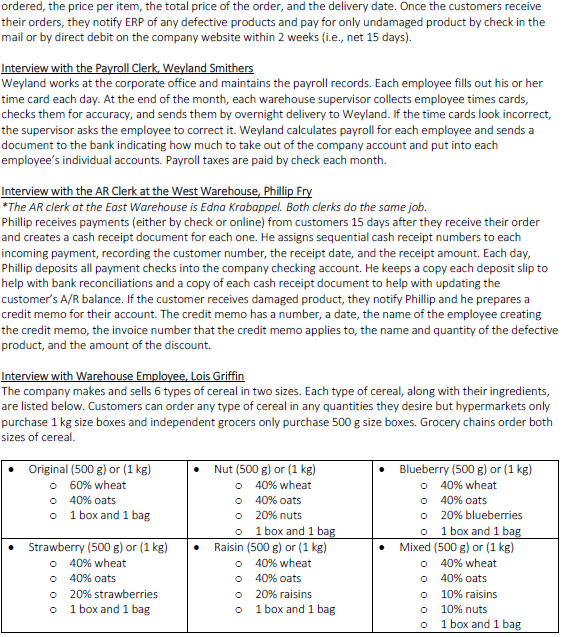

ERP Muesli manufactures cereal that they sell out of two manufacturing warehouses to three types of customers: 1) hypermarkets, 2) grocery chains, and 3) independent grocers. Until recently, all of ERP'S recordkeeping was done manually. Each warehouse would keep track of its own manufacturing costs and revenue. Every month, the warehouses would send their records to the corporate office where bills were paid, and financial statements prepared. They have now hired an accounting intern to go through all the paper documents and enter the data into an Excel spreadsheet. They have hired you to design a database accounting system for their business, construct a prototype system in Access, and provide some related accounting advice. They want to eventually be able to import the Excel data into the Access database so that it will be easier to create financial statements. Linda prepares checks for payments to cereal suppliers and other vendors. The warehouses send her copies of purchase orders every day, so it is important that suppliers are paid quickly to prevent any delays in delivery. Linda tries to pay all bills from suppliers within one week of receipt. Bills from other vendors-such as utility companies and repair shops are paid within 30 days. When Linda pays a bill, she stamps the document as paid and handwrites the check number, payment date, and check amount near the stamp. These documents are then stored in a filing cabinet in the AP office. Interview with Manufacturing Warehouse Su Bob is the supervisor for the West Manufacturing Warehouse and Hank is the supervisor for the East Manufacturing Warehouse. Customers call to place orders for cereal. Usually, they order about one month in advance and all orders are kept in a log. Every day, the supervisors look at the log to determine what types of ingredients they need to ensure are on hand to fill upcoming orters. If a purchase needs to be made, a purchase order document is created. It has a po number, a date, name of the ingredient(s) being ordered, quantity of ingredient(s) being ordered, name of the employee placing the order, and date of desired delivery. The prices are not on the purchase order because prices for ingredients are based on supply and change regularly. ERP always just pays the market price for their ingredients. Sometimes, certain ingredients are not available. When this happens, the supervisors call the customers to modify or cancel the order. Even though the supervisors consult the list of orders when making purchases, production is not run for each, individual customer order (i.e., not a job shop). Production is run based on the supervisor estimates of future customer demand for Bob Belcher and Hank Hill the product. When a shipment of ingredients arrives at the warehouse, employees unload the truck, and move the ingredients into the storage location (raw materials inventory). From there, ingredients are pulled into production (work in process) as needed. Each product (type of cereal) is produced in batches. When ingredients are pulled into production for a batch of cereal, a materials requisition is created to identify the individual ingredients and quantities needed for the product being produced. Each materials requisition has a number, a date, the name of the employee preparing the document, a list of the ingredients with quantities, and the name of the cereal product being produced. Multiple materials requisitions may be required to complete a single product production run. Every afternoon, employees prepare customer orders and load them onto the company delivery truck along with a copy of the customer order that serves as an invoice. The customer orders list the customer name, the date of the order, the name of the employee taking the order, the items ordered, the quantity of the items ordered, the price per item, the total price of the order, and the delivery date. Once the customers receive their orders, they notify ERP of any defective products and pay for only undamaged product by check in the mail or by direct debit on the company website within 2 weeks (i.e., net 15 days). ne Weyland works at the corporate office and maintains the payroll records. Each employee fills out his or her time card each day. At the end of the month, each warehouse supervisor collects employee times cards, checks them for accuracy, and sends them by overnight delivery to Weyland. If the time cards look incorrect, the supervisor asks the employee to correct it. Weyland calculates payroll for each employee and sends a document to the bank indicating how much to take out of the company account and put into each employee's individual accounts. Payroll taxes are paid by check each month. Interview with the AR Clerk at the West Warehouse, Phillip Fr The AR clerk at the East Warehouse is Edna Krabappel. Both clerks do the same job. Phillip receives payments (either by check or online) from customers 15 days after they receive their order and creates a cash receipt document for each one. He assigns sequential cash receipt numbers to each incoming payment, recording the customer number, the receipt date, and the receipt amount. Each day Phillip deposits all payment checks into the company checking account. He keeps a copy each deposit slip to help with bank reconciliations and a copy of each cash receipt document to help with updating the customer's A/R balance. If the customer receives damaged product, they notify Phillip and he prepares a credit memo for their account. The credit memo has a number, a date, the name of the employee creating the credit memo, the invoice number that the credit memo applies to, the name and quantity of the defective product, and the amount of the discount. The company makes and sells 6 types of cereal in two sizes. Each type of cereal, along with their ingredients, are listed below. Customers can order any type of cereal in any quantities they desire but hypermarkets only purchase 1 kg size boxes and independent grocers only purchase 500 g size boxes. Grocery chains order both sizes of cereal Original (500 g) or (1 kg) Nut (500 g) or (1 kg) Blueberry (500 g) or (1 kg) 60% wheat 40% oats 1 box and 1 bag 40% wheat 40% oats 20% nuts 1 box and 1 ba 40% wheat 40% oats 20% blueberries o o o o o o o o 1 box and 1 Mixed (500 g) or (1 kg) . Strawberry (500 g) or (1kg)Raisin (500 g) or (1 kg) 40% wheat 40% oats 40% wheat 40% oats 20% raisins 40% wheat o 40% oats o 10% raisins o 10% nuts o 1 box and 1 bag o 20% strawberries o 1 box and 1 bag o o 1 box and 1 bag After gaining an understanding of ERP's business processes, document each current process with a business process activity diagram using business process modeling notation (BPMN). Models to include (at minimum): Communications and activities with external entities Overall ERP process (with noted collapsed subprocesses) . Expanded subprocesses (can do more) o Sales/Cash receipts o Purchases/Cash disbursements o Conversion o Payroll Prepare a Structure Diagram Using the information gained from the interviews and the AlS book (SEE PAGE 204 in CH 8), prepare an integrated UML class diagram that incorporates the data requirements of all of ERP's business processes. Consider the REA(T) model as you proceed with the project so you can submit a professional looking model with your final report. Label each of the tables as a resource, event, agent, type, or link. Use draw.io to create your model. Ensure that paths are clear (i.e., no 90-degree angles on intersecting relationship lines) and include appropriate cardinalities. Provide a verbal description of each relationship depicted in the diagram (i.e., each sales order can have only one customer, etc.) ERP Muesli manufactures cereal that they sell out of two manufacturing warehouses to three types of customers: 1) hypermarkets, 2) grocery chains, and 3) independent grocers. Until recently, all of ERP'S recordkeeping was done manually. Each warehouse would keep track of its own manufacturing costs and revenue. Every month, the warehouses would send their records to the corporate office where bills were paid, and financial statements prepared. They have now hired an accounting intern to go through all the paper documents and enter the data into an Excel spreadsheet. They have hired you to design a database accounting system for their business, construct a prototype system in Access, and provide some related accounting advice. They want to eventually be able to import the Excel data into the Access database so that it will be easier to create financial statements. Linda prepares checks for payments to cereal suppliers and other vendors. The warehouses send her copies of purchase orders every day, so it is important that suppliers are paid quickly to prevent any delays in delivery. Linda tries to pay all bills from suppliers within one week of receipt. Bills from other vendors-such as utility companies and repair shops are paid within 30 days. When Linda pays a bill, she stamps the document as paid and handwrites the check number, payment date, and check amount near the stamp. These documents are then stored in a filing cabinet in the AP office. Interview with Manufacturing Warehouse Su Bob is the supervisor for the West Manufacturing Warehouse and Hank is the supervisor for the East Manufacturing Warehouse. Customers call to place orders for cereal. Usually, they order about one month in advance and all orders are kept in a log. Every day, the supervisors look at the log to determine what types of ingredients they need to ensure are on hand to fill upcoming orters. If a purchase needs to be made, a purchase order document is created. It has a po number, a date, name of the ingredient(s) being ordered, quantity of ingredient(s) being ordered, name of the employee placing the order, and date of desired delivery. The prices are not on the purchase order because prices for ingredients are based on supply and change regularly. ERP always just pays the market price for their ingredients. Sometimes, certain ingredients are not available. When this happens, the supervisors call the customers to modify or cancel the order. Even though the supervisors consult the list of orders when making purchases, production is not run for each, individual customer order (i.e., not a job shop). Production is run based on the supervisor estimates of future customer demand for Bob Belcher and Hank Hill the product. When a shipment of ingredients arrives at the warehouse, employees unload the truck, and move the ingredients into the storage location (raw materials inventory). From there, ingredients are pulled into production (work in process) as needed. Each product (type of cereal) is produced in batches. When ingredients are pulled into production for a batch of cereal, a materials requisition is created to identify the individual ingredients and quantities needed for the product being produced. Each materials requisition has a number, a date, the name of the employee preparing the document, a list of the ingredients with quantities, and the name of the cereal product being produced. Multiple materials requisitions may be required to complete a single product production run. Every afternoon, employees prepare customer orders and load them onto the company delivery truck along with a copy of the customer order that serves as an invoice. The customer orders list the customer name, the date of the order, the name of the employee taking the order, the items ordered, the quantity of the items ordered, the price per item, the total price of the order, and the delivery date. Once the customers receive their orders, they notify ERP of any defective products and pay for only undamaged product by check in the mail or by direct debit on the company website within 2 weeks (i.e., net 15 days). ne Weyland works at the corporate office and maintains the payroll records. Each employee fills out his or her time card each day. At the end of the month, each warehouse supervisor collects employee times cards, checks them for accuracy, and sends them by overnight delivery to Weyland. If the time cards look incorrect, the supervisor asks the employee to correct it. Weyland calculates payroll for each employee and sends a document to the bank indicating how much to take out of the company account and put into each employee's individual accounts. Payroll taxes are paid by check each month. Interview with the AR Clerk at the West Warehouse, Phillip Fr The AR clerk at the East Warehouse is Edna Krabappel. Both clerks do the same job. Phillip receives payments (either by check or online) from customers 15 days after they receive their order and creates a cash receipt document for each one. He assigns sequential cash receipt numbers to each incoming payment, recording the customer number, the receipt date, and the receipt amount. Each day Phillip deposits all payment checks into the company checking account. He keeps a copy each deposit slip to help with bank reconciliations and a copy of each cash receipt document to help with updating the customer's A/R balance. If the customer receives damaged product, they notify Phillip and he prepares a credit memo for their account. The credit memo has a number, a date, the name of the employee creating the credit memo, the invoice number that the credit memo applies to, the name and quantity of the defective product, and the amount of the discount. The company makes and sells 6 types of cereal in two sizes. Each type of cereal, along with their ingredients, are listed below. Customers can order any type of cereal in any quantities they desire but hypermarkets only purchase 1 kg size boxes and independent grocers only purchase 500 g size boxes. Grocery chains order both sizes of cereal Original (500 g) or (1 kg) Nut (500 g) or (1 kg) Blueberry (500 g) or (1 kg) 60% wheat 40% oats 1 box and 1 bag 40% wheat 40% oats 20% nuts 1 box and 1 ba 40% wheat 40% oats 20% blueberries o o o o o o o o 1 box and 1 Mixed (500 g) or (1 kg) . Strawberry (500 g) or (1kg)Raisin (500 g) or (1 kg) 40% wheat 40% oats 40% wheat 40% oats 20% raisins 40% wheat o 40% oats o 10% raisins o 10% nuts o 1 box and 1 bag o 20% strawberries o 1 box and 1 bag o o 1 box and 1 bag After gaining an understanding of ERP's business processes, document each current process with a business process activity diagram using business process modeling notation (BPMN). Models to include (at minimum): Communications and activities with external entities Overall ERP process (with noted collapsed subprocesses) . Expanded subprocesses (can do more) o Sales/Cash receipts o Purchases/Cash disbursements o Conversion o Payroll Prepare a Structure Diagram Using the information gained from the interviews and the AlS book (SEE PAGE 204 in CH 8), prepare an integrated UML class diagram that incorporates the data requirements of all of ERP's business processes. Consider the REA(T) model as you proceed with the project so you can submit a professional looking model with your final report. Label each of the tables as a resource, event, agent, type, or link. Use draw.io to create your model. Ensure that paths are clear (i.e., no 90-degree angles on intersecting relationship lines) and include appropriate cardinalities. Provide a verbal description of each relationship depicted in the diagram (i.e., each sales order can have only one customer, etc.)