Answered step by step

Verified Expert Solution

Question

1 Approved Answer

Established in 1998, Nutripex is a manufacturer of a wide range of vitamins and food supplements for supply to supermarkets. Most of the products, such

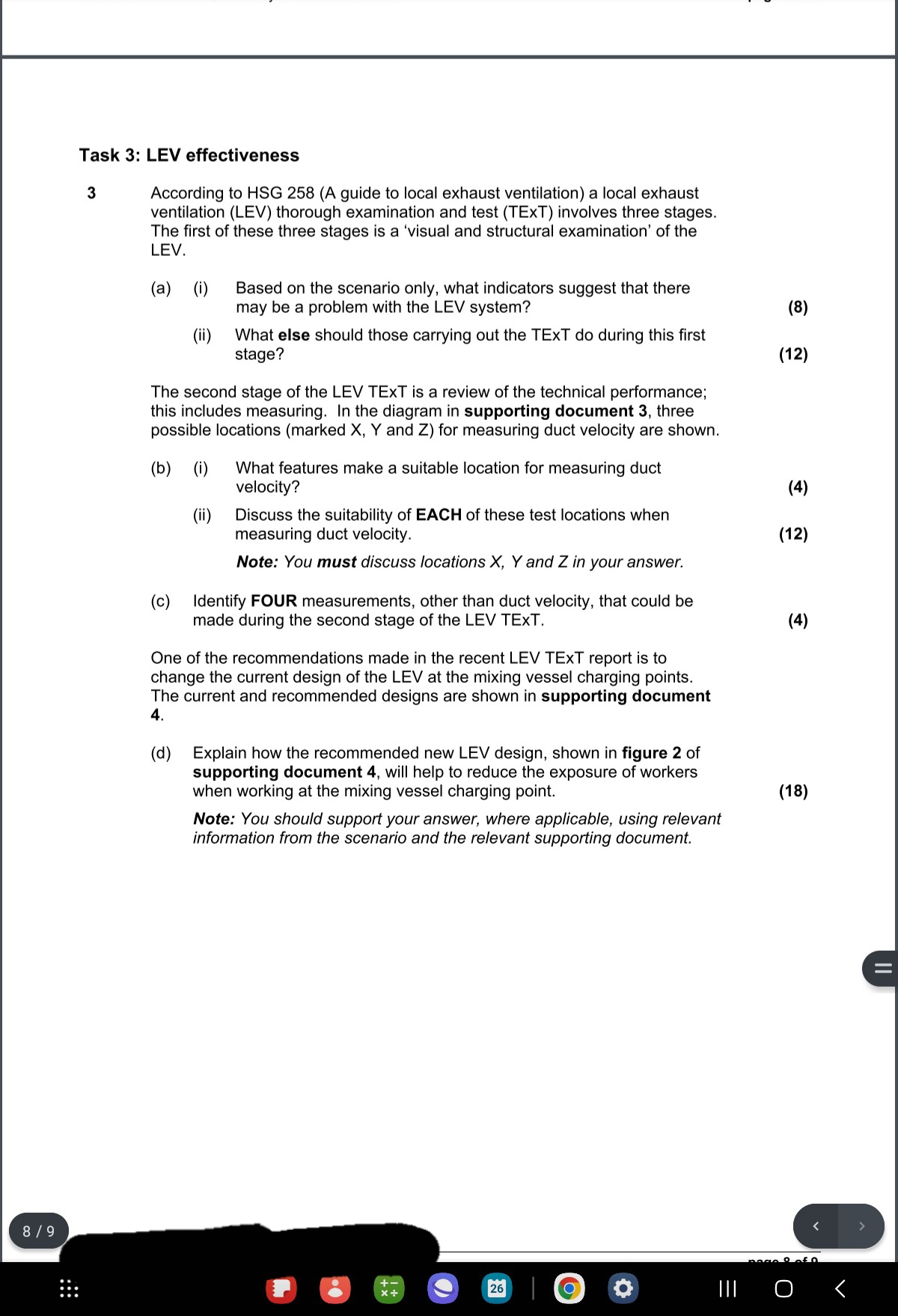

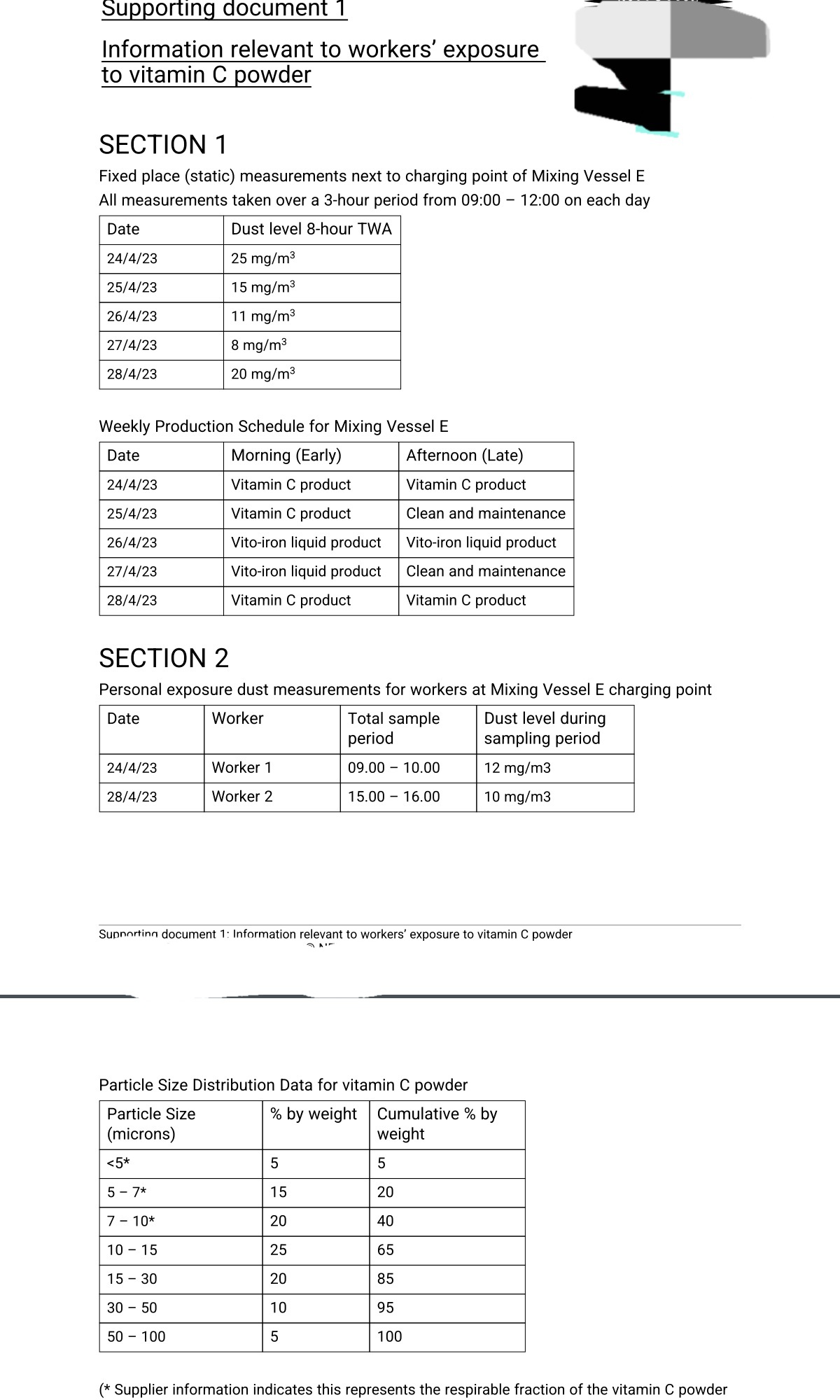

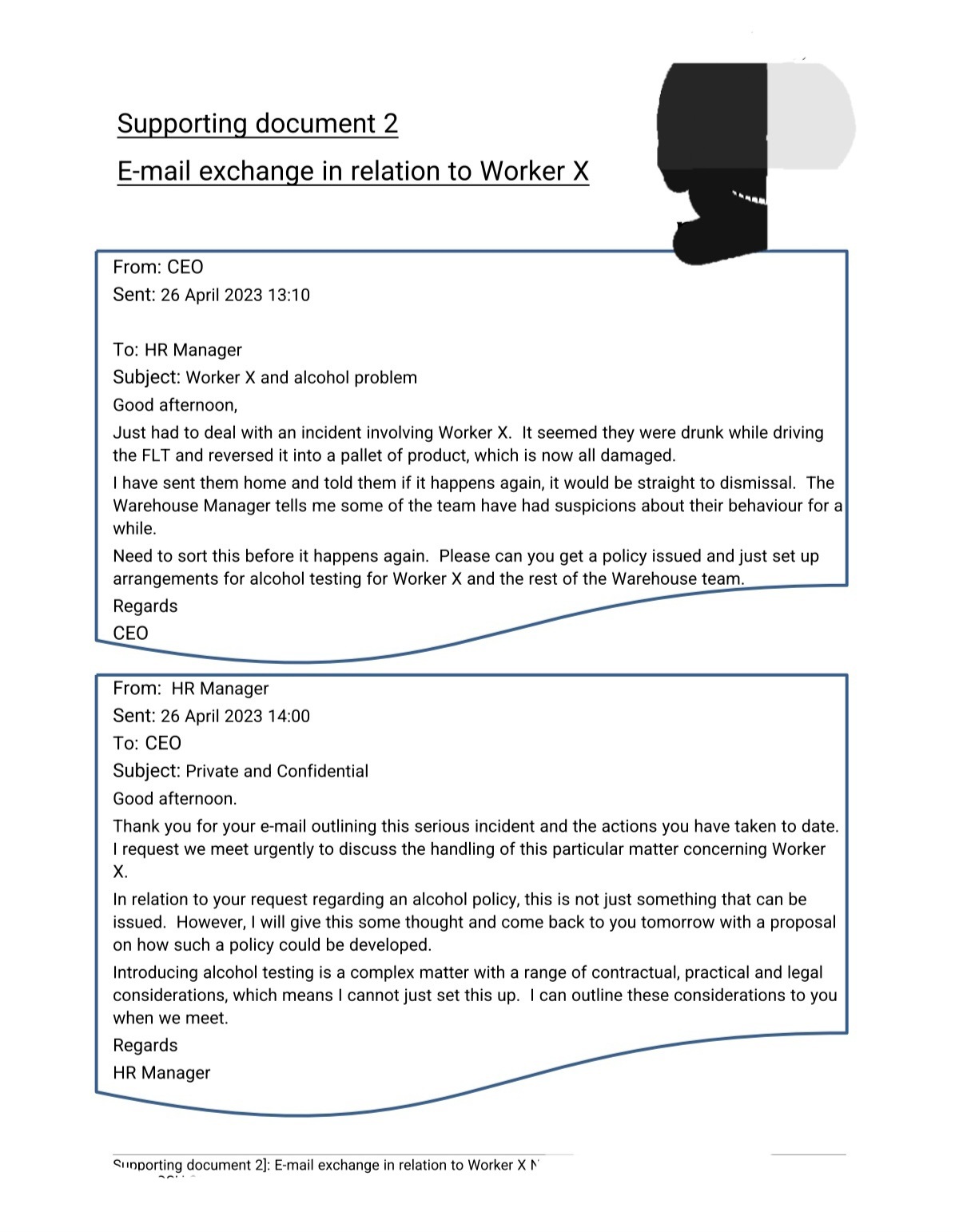

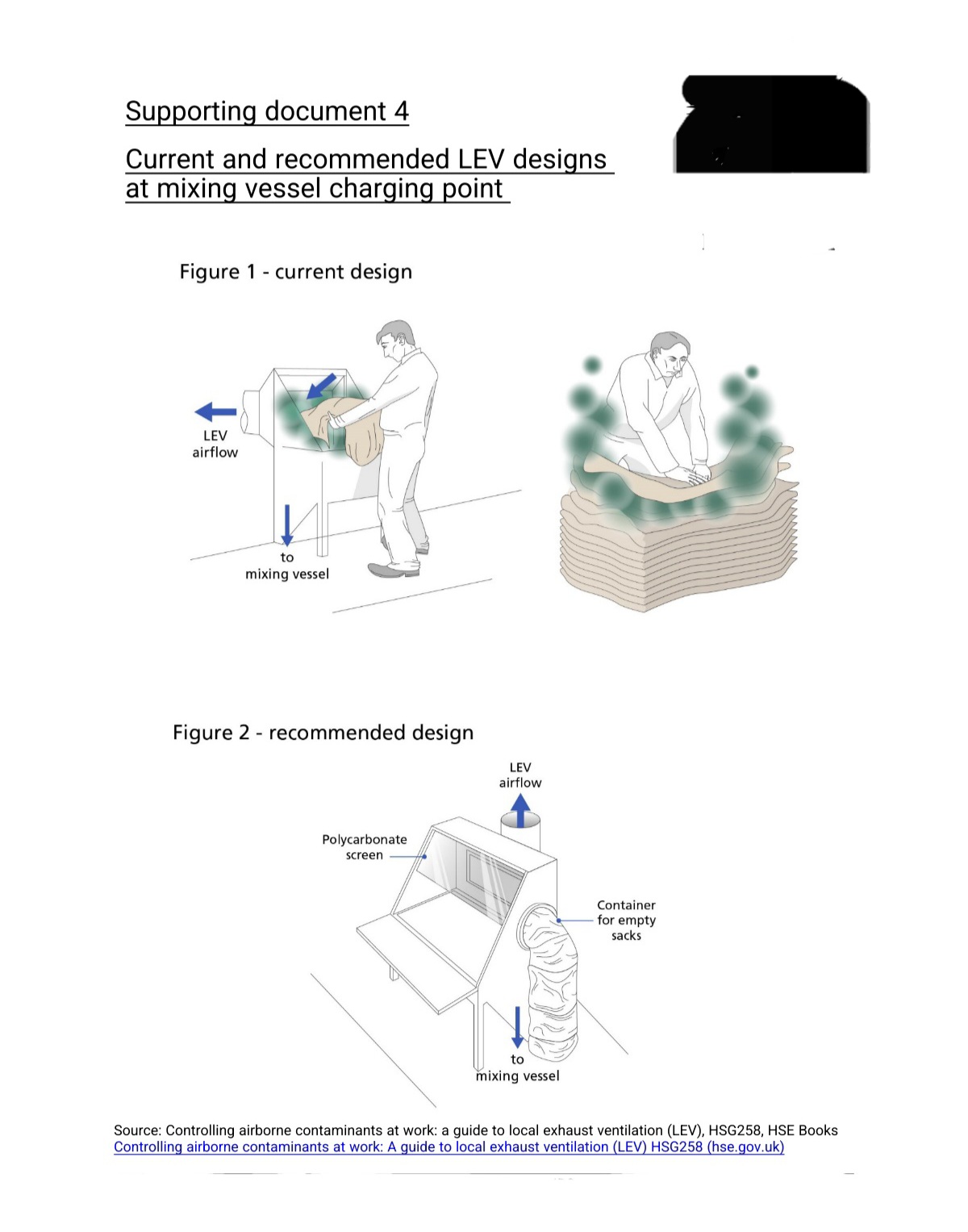

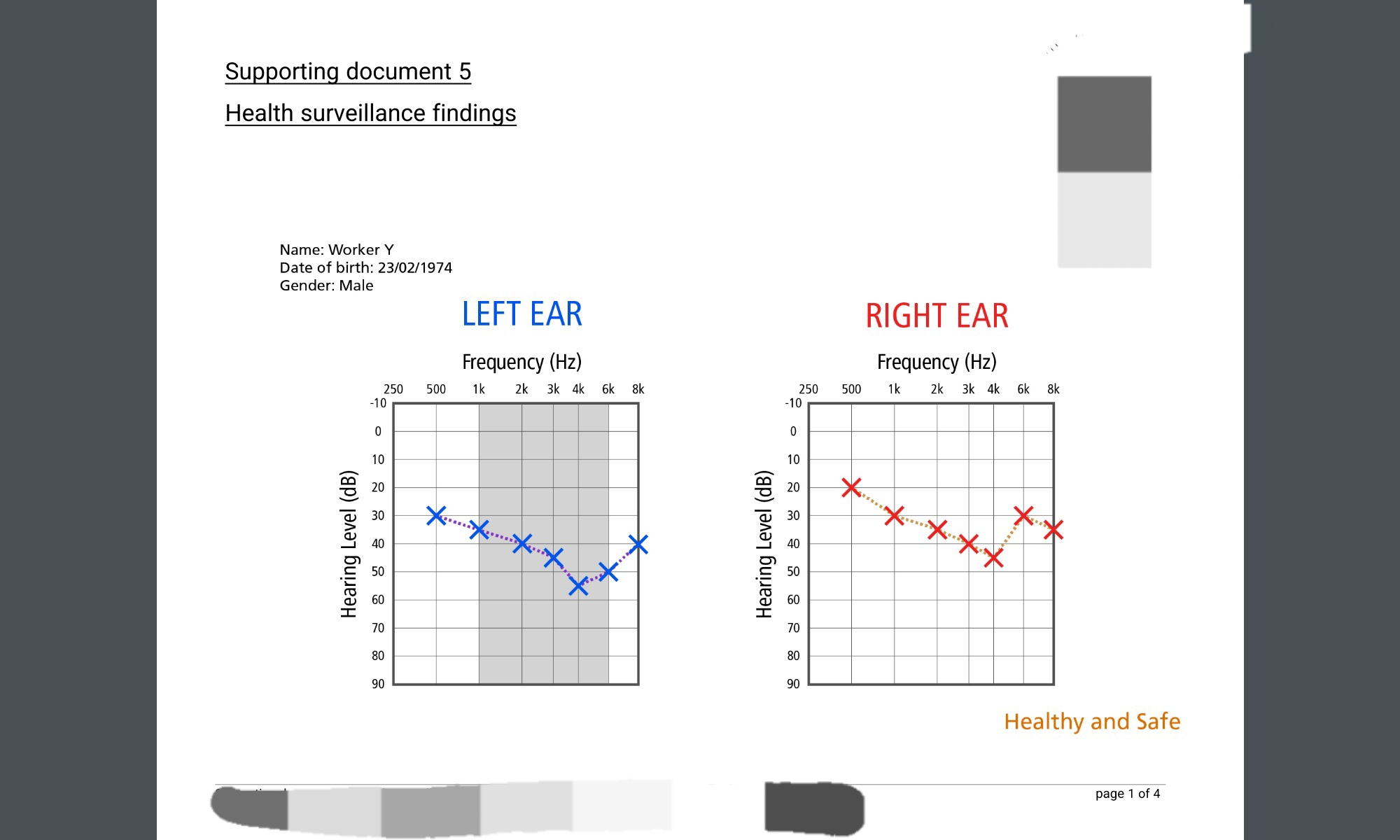

Established in 1998, Nutripex is a manufacturer of a wide range of vitamins and food supplements for supply to supermarkets. Most of the products, such as Vitamin C, are solid tablets; some products, such as Vito-iron, are in liquid form. Nutripex operates in a modern industrial unit, consisting of a large production department, some office space, and a warehouse. There are 150 workers at the site, and the majority of these work in the production department. There is a break room and changing area with lockers that workers can use. The workers are allowed two 15-minute breaks and a 30 minute break for lunch during a normal 8-hour shift. There is an early and late shift operating five days a week. Personal protective equipment (PPE) is provided to all workers in the form of earplugs, safety glasses, disposable dust masks and overalls. All workers wear the overalls provided, to protect their own clothes. The use of the rest of the PPE provided is sporadic. The dust masks are particularly unpopular with workers who have beards. Vitamin and food-supplement production Mixing The vitamins and supplements are made within the production department, which consists of three main areas: mixing, tableting and packaging. The production manager (PM) is responsible for all the workers in these areas. The mixing area is particularly busy and noisy, as it has five mixing machines (designated by the letters A to E ) often operating simultaneously. At the start of the production of a batch of product, raw materials are emptied into the mixing vessels at the charging point above the mixer. Most of the raw materials are usually in the form of powders, in 25kg sacks. There are typically 30 sacks of raw materials added to each batch. To empty the contents of one of these sacks into the mixing vessel the 'rip and tip' method is used. This involves the worker standing on a platform that provides access to the charging point, holding the sack, while cutting the end open with a knife. The sack contents are then poured into the mixing vessel. The empty sacks are then flattened and stacked nearby. It takes around an hour to add all the raw materials to the mixing vessel at the start of each batch. Workers often complain about getting too hot while carrying out this work. During the production, dust can be seen in the air, even though there is local exhaust ventilation (LEV) at the charging point. There have been complaints from some of the workers about the dust, especially when handling vitamin C (ascorbic acid) powder. Workers also point out that there is a thin layer of dust on most surfaces, not just at the charging point, but throughout the production department. As a result of this, the PM has reviewed the raw material safety data sheet (SDS) for vitamin C powder. The vitamin C powder is described as non-hazardous and there is no occupational exposure limit assigned. Therefore, the PM has concluded that a hazardous substance risk assessment for the handling of this raw material is not required. On any given day, any one of the mixing machines may be mixing a different product from any of the other machines. However, the weekly production schedule for a specific mixing vessel is often the same, with certain days allocated to the production of a particular product. For example, if one product is being manufactured all day in one mixing vessel, it is likely that up to three batches of that product will be made in one day. Usually, two batches in the morning (starting at 09.00 and 11.00) and one batch in the afternoon (starting at 14.00). When all of the raw materials are sufficiently blended in the mixing machine, the product is moved to the tableting machine. When manufacturing vitamin tablets, the particle size is extremely important in determining how well the product will run through the tableting machine. When the raw materials such as vitamin C powder are delivered, information about the particle size distribution is provided by the supplier. LEV ducting runs throughout the whole production department. This ducting is often fixed high above the machines, with branch ducts to the charging points for each of the five mixing machines A to E, and tableting machines 1 and 2. There are a number of joints in the ducting; not all of them are sealed well and dust can be seen escaping in some places. The mixing machines and surfaces that workers can reach are cleaned down regularly as part of the weekly production schedule. Tableting In the tableting area the product makes its way through several processes, including a punch press; here, pressure is applied to the product by dies to form the completed tablet. The tablets are ejected onto a vibrating belt to shake off any loose dust. The two tableting machines are particularly noisy. In this area, there is a long run of LEV ducting that branches to two hoods, one for each tableting machine. Some of this ducting is sagging in places and has adhesive tape wrapped around the joints. In most cases this has made the sagging worse. Nearby is the LEV dust-collector and air-cleaner unit. Workers in this area are responsible for changing the collection bags and have commented on how, recently, the bags are taking much longer to fill up. Also located here is the fan for the LEV system. When the fan is running it is very difficult to have a conversation in this area. Workers are supplied with earplugs, that are not used regularly. When questioned, workers frequently say that they have lost one or both of their earplugs. Several workers, including Worker Y, have been working in the tableting area since they joined Nutripex, 18 months ago. They had all previously worked in a nearby drinks-bottling plant, that was making people redundant just as Nutripex was recruiting for more production workers. Packaging The final stage in the process of producing vitamins and supplements is packaging. Once the tablets are packaged, they are labelled, boxed, and placed on pallets. The pallets of finished product are shrink-wrapped and stored in the warehouse before despatch to customers. The warehouse is used for the storage of raw materials and finished products. The warehouse manager (WM) has a team of forklift truck (FLT) drivers and warehouse workers. This is also where the maintenance team are located. All of these workers have a good working relationship, and this extends to frequent social events outside of work. Worker X Recently, several of the workers in the warehouse have been concerned about Worker X, one of the FLT drivers. There have been several occasions when Worker X has been reported to the WM for driving erratically. The WM has suggested to Worker X that they attend an FLT driver refresher training course, but so far Worker X has been reluctant to do this. It is 26 April, and in the warehouse the early shift is about to start. Worker W (one of the other FLT drivers) is awaiting the arrival of their colleague, Worker X. They have worked together for a long time and have formed a strong bond over the years. Recently, Worker W has expressed concern, because Worker X hardly spends any time talking to them and does not laugh and joke or socialise, as they used to. The two workers used to spend breaks and lunch together in the break room, but this has recently stopped. The early shift has started, and Worker W goes to get on with their job. An hour into the shift, Worker X arrives for work and goes into the changing area. Worker W follows them and asks if they are feeling alright, showing typical concern for their colleague's wellbeing. Worker X mutters that they are 'fine' and that they wish everyone would leave them alone. Worker W is concerned about their friend, but decides not to question them any further. The WM is going through the job sheets with Workers X and W, indicating there are five urgent despatch jobs that must be finished today. The WM jokes with Worker X about them being late for the second time that week, and Worker X makes the same excuse as a previous time. page 3 of 9 During the morning it has again been reported to the WM that Worker X has been driving the FLT erratically. The WM makes a mental note to speak to Worker X later, when the shift is coming to an end. In the meantime, the WM decides to have a quiet word with Worker W. During the morning it has again been reported to the WM that Worker X has been driving the FLT erratically. The WM makes a mental note to speak to Worker X later, when the shift is coming to an end. In the meantime, the WM decides to have a quiet word with Worker W. Worker W feels awkward and does not want to make things worse for Worker X, but does mention to the WM that the team are concerned about Worker X. Worker W also has suspicions that Worker X may have problems at home, as they are drinking a lot of alcohol and seem to be taking longer breaks. Half an hour after lunch, the WM is in their office preparing for an off-site meeting with an important customer, when they see Worker X reverse into a pallet of finished product that was on the urgent despatch list. The WM is angered by this, especially because they are in a rush to get to their meeting. They phone the CEO and ask them to speak to Worker X. The WM quickly explains to the CEO what has been happening recently, the suspicions raised by other workers, and about the incident that has just occurred. The CEO does not want to hear excuses when they speak to Worker X. The CEO immediately accuses Worker X of being drunk at work and says that this will not be tolerated. They issue a warning to Worker X and state that if anything like this happens again, they will be immediately dismissed from their job. Before Worker X can say anything, the CEO tells them to go home and sober up! Involvement of specialists The PM has taken some noise readings at various points within the tableting area, as part of a risk assessment. This has never been done before. Noise levels have been found to be between 84 dB(A) and 86dB(A). Because of these findings the human resources (HR) manager engaged a consultant from Healthy and Safe (HaS) to carry out more detailed noise measurements and advise on noise reduction methods and a health surveillance programme. Based on HaS's recommendations, the HR manager is introducing audiometry testing for all existing workers in the tableting department and any new workers going forward. Workers remain concerned about the levels of dust, so Nutripex have decided to engage an Occupational Hygienist (OH) to help review exposure of workers to vitamin C powder and other raw materials. Some initial results of the OH's work are given in supporting document 1. In the last couple of weeks there have been frequent alarms on the LEV control panel. As a result of this, the PM arranged for a thorough inspection and test (TExT) of the LEV, which has just been completed by a competent external contractor, AirTest. The PM is looking through the results and recommendations in AirTest's report. One of the recommendations is to change the current design of the LEV at the charging point where raw materials are added to the mixing machines. The PM and HR manager have now met with the OH to go through the dust exposure measurements and decide what to do next. The OH agrees that the LEV design change recommended by AirTest would be helpful, but understands that this will take some time. In the meantime, the OH is concerned about the levels of dust exposure and recommends that workers handling vitamin C powder should wear tight-fitting respiratory protective equipment (RPE). The OH has made recommendations about the specific type of RPE and the PM says that they will help ensure that it is used, just as soon as it arrives from the supplier. page 4 of 9 Supporting Documents 1. Information about workers' exposure to vitamin C 2. Email about Worker X 3. Section of LEV system in tableting department 4. Current and recommended LEV designs at mixing vessel charging point 5. Health surveillance findings sk 3: LEV effectiveness According to HSG 258 (A guide to local exhaust ventilation) a local exhaust ventilation (LEV) thorough examination and test (TEXT) involves three stages. The first of these three stages is a 'visual and structural examination' of the LEV. (a) (i) Based on the scenario only, what indicators suggest that there may be a problem with the LEV system? (8) (ii) What else should those carrying out the TEXT do during this first stage? (12) The second stage of the LEV TExT is a review of the technical performance; this includes measuring. In the diagram in supporting document 3 , three possible locations (marked X,Y and Z ) for measuring duct velocity are shown. (b) (i) What features make a suitable location for measuring duct velocity? (4) (ii) Discuss the suitability of EACH of these test locations when measuring duct velocity. Note: You must discuss locations X,Y and Z in your answer. (c) Identify FOUR measurements, other than duct velocity, that could be made during the second stage of the LEV TEXT. (4) One of the recommendations made in the recent LEV TEXT report is to change the current design of the LEV at the mixing vessel charging points. The current and recommended designs are shown in supporting document 4. (d) Explain how the recommended new LEV design, shown in figure 2 of supporting document 4 , will help to reduce the exposure of workers when working at the mixing vessel charging point. (18) Note: You should support your answer, where applicable, using relevant information from the scenario and the relevant supporting document. Supporting document 1 Information relevant to workers' exposure to vitamin C powder SECTION 1 Fixed place (static) measurements next to charging point of Mixing Vessel E All measurements taken over a 3-hour period from 09:00 - 12:00 on each day Weekly Production Schedule for Mixing Vessel E SECTION 2 Personal exposure dust measurements for workers at Mixing Vessel E charging point Supnnrtina document 1: Information relevant to workers' exposure to vitamin C powder Particle Size Distrihution Data for vitamin C nowder Supporting document 2 E-mail exchange in relation to Worker X From: CEO Sent: 26 April 2023 13:10 To: HR Manager Subject: Worker X and alcohol problem Good afternoon, Just had to deal with an incident involving Worker X. It seemed they were drunk while driving the FLT and reversed it into a pallet of product, which is now all damaged. I have sent them home and told them if it happens again, it would be straight to dismissal. The Warehouse Manager tells me some of the team have had suspicions about their behaviour for a while. Need to sort this before it happens again. Please can you get a policy issued and just set up arrangements for alcohol testing for Worker X and the rest of the Warehouse team. Regards CEO From: HR Manager Sent: 26 April 2023 14:00 To: CEO Subject: Private and Confidential Good afternoon. Thank you for your e-mail outlining this serious incident and the actions you have taken to date. I request we meet urgently to discuss the handling of this particular matter concerning Worker x. In relation to your request regarding an alcohol policy, this is not just something that can be issued. However, I will give this some thought and come back to you tomorrow with a proposal on how such a policy could be developed. Introducing alcohol testing is a complex matter with a range of contractual, practical and legal considerations, which means I cannot just set this up. I can outline these considerations to you when we meet. Regards HR Manager Snporting document 2]: E-mail exchange in relation to Worker A Supporting document 3 Section of LEV system in tableting department Duct diameters: at X30cm at Y50cm at Z50cm Supporting document 3: Section of LEV System - 1 page 1 of 4 Supporting document 4 Current and recommended LEV designs at mixing vessel charging point Figure 1 - current design Figure 2 - recommended design Source: Controlling airborne contaminants at work: a guide to local exhaust ventilation (LEV), HSG258, HSE Books Controlling airborne contaminants at work: A guide to local exhaust ventilation (LEV) HSG258 (hse.gov.uk) Supporting document 5 Health surveillance findings Name: Worker Y Date of birth: 23/02/1974 Gendar. M Malo Healthy and Safe

Established in 1998, Nutripex is a manufacturer of a wide range of vitamins and food supplements for supply to supermarkets. Most of the products, such as Vitamin C, are solid tablets; some products, such as Vito-iron, are in liquid form. Nutripex operates in a modern industrial unit, consisting of a large production department, some office space, and a warehouse. There are 150 workers at the site, and the majority of these work in the production department. There is a break room and changing area with lockers that workers can use. The workers are allowed two 15-minute breaks and a 30 minute break for lunch during a normal 8-hour shift. There is an early and late shift operating five days a week. Personal protective equipment (PPE) is provided to all workers in the form of earplugs, safety glasses, disposable dust masks and overalls. All workers wear the overalls provided, to protect their own clothes. The use of the rest of the PPE provided is sporadic. The dust masks are particularly unpopular with workers who have beards. Vitamin and food-supplement production Mixing The vitamins and supplements are made within the production department, which consists of three main areas: mixing, tableting and packaging. The production manager (PM) is responsible for all the workers in these areas. The mixing area is particularly busy and noisy, as it has five mixing machines (designated by the letters A to E ) often operating simultaneously. At the start of the production of a batch of product, raw materials are emptied into the mixing vessels at the charging point above the mixer. Most of the raw materials are usually in the form of powders, in 25kg sacks. There are typically 30 sacks of raw materials added to each batch. To empty the contents of one of these sacks into the mixing vessel the 'rip and tip' method is used. This involves the worker standing on a platform that provides access to the charging point, holding the sack, while cutting the end open with a knife. The sack contents are then poured into the mixing vessel. The empty sacks are then flattened and stacked nearby. It takes around an hour to add all the raw materials to the mixing vessel at the start of each batch. Workers often complain about getting too hot while carrying out this work. During the production, dust can be seen in the air, even though there is local exhaust ventilation (LEV) at the charging point. There have been complaints from some of the workers about the dust, especially when handling vitamin C (ascorbic acid) powder. Workers also point out that there is a thin layer of dust on most surfaces, not just at the charging point, but throughout the production department. As a result of this, the PM has reviewed the raw material safety data sheet (SDS) for vitamin C powder. The vitamin C powder is described as non-hazardous and there is no occupational exposure limit assigned. Therefore, the PM has concluded that a hazardous substance risk assessment for the handling of this raw material is not required. On any given day, any one of the mixing machines may be mixing a different product from any of the other machines. However, the weekly production schedule for a specific mixing vessel is often the same, with certain days allocated to the production of a particular product. For example, if one product is being manufactured all day in one mixing vessel, it is likely that up to three batches of that product will be made in one day. Usually, two batches in the morning (starting at 09.00 and 11.00) and one batch in the afternoon (starting at 14.00). When all of the raw materials are sufficiently blended in the mixing machine, the product is moved to the tableting machine. When manufacturing vitamin tablets, the particle size is extremely important in determining how well the product will run through the tableting machine. When the raw materials such as vitamin C powder are delivered, information about the particle size distribution is provided by the supplier. LEV ducting runs throughout the whole production department. This ducting is often fixed high above the machines, with branch ducts to the charging points for each of the five mixing machines A to E, and tableting machines 1 and 2. There are a number of joints in the ducting; not all of them are sealed well and dust can be seen escaping in some places. The mixing machines and surfaces that workers can reach are cleaned down regularly as part of the weekly production schedule. Tableting In the tableting area the product makes its way through several processes, including a punch press; here, pressure is applied to the product by dies to form the completed tablet. The tablets are ejected onto a vibrating belt to shake off any loose dust. The two tableting machines are particularly noisy. In this area, there is a long run of LEV ducting that branches to two hoods, one for each tableting machine. Some of this ducting is sagging in places and has adhesive tape wrapped around the joints. In most cases this has made the sagging worse. Nearby is the LEV dust-collector and air-cleaner unit. Workers in this area are responsible for changing the collection bags and have commented on how, recently, the bags are taking much longer to fill up. Also located here is the fan for the LEV system. When the fan is running it is very difficult to have a conversation in this area. Workers are supplied with earplugs, that are not used regularly. When questioned, workers frequently say that they have lost one or both of their earplugs. Several workers, including Worker Y, have been working in the tableting area since they joined Nutripex, 18 months ago. They had all previously worked in a nearby drinks-bottling plant, that was making people redundant just as Nutripex was recruiting for more production workers. Packaging The final stage in the process of producing vitamins and supplements is packaging. Once the tablets are packaged, they are labelled, boxed, and placed on pallets. The pallets of finished product are shrink-wrapped and stored in the warehouse before despatch to customers. The warehouse is used for the storage of raw materials and finished products. The warehouse manager (WM) has a team of forklift truck (FLT) drivers and warehouse workers. This is also where the maintenance team are located. All of these workers have a good working relationship, and this extends to frequent social events outside of work. Worker X Recently, several of the workers in the warehouse have been concerned about Worker X, one of the FLT drivers. There have been several occasions when Worker X has been reported to the WM for driving erratically. The WM has suggested to Worker X that they attend an FLT driver refresher training course, but so far Worker X has been reluctant to do this. It is 26 April, and in the warehouse the early shift is about to start. Worker W (one of the other FLT drivers) is awaiting the arrival of their colleague, Worker X. They have worked together for a long time and have formed a strong bond over the years. Recently, Worker W has expressed concern, because Worker X hardly spends any time talking to them and does not laugh and joke or socialise, as they used to. The two workers used to spend breaks and lunch together in the break room, but this has recently stopped. The early shift has started, and Worker W goes to get on with their job. An hour into the shift, Worker X arrives for work and goes into the changing area. Worker W follows them and asks if they are feeling alright, showing typical concern for their colleague's wellbeing. Worker X mutters that they are 'fine' and that they wish everyone would leave them alone. Worker W is concerned about their friend, but decides not to question them any further. The WM is going through the job sheets with Workers X and W, indicating there are five urgent despatch jobs that must be finished today. The WM jokes with Worker X about them being late for the second time that week, and Worker X makes the same excuse as a previous time. page 3 of 9 During the morning it has again been reported to the WM that Worker X has been driving the FLT erratically. The WM makes a mental note to speak to Worker X later, when the shift is coming to an end. In the meantime, the WM decides to have a quiet word with Worker W. During the morning it has again been reported to the WM that Worker X has been driving the FLT erratically. The WM makes a mental note to speak to Worker X later, when the shift is coming to an end. In the meantime, the WM decides to have a quiet word with Worker W. Worker W feels awkward and does not want to make things worse for Worker X, but does mention to the WM that the team are concerned about Worker X. Worker W also has suspicions that Worker X may have problems at home, as they are drinking a lot of alcohol and seem to be taking longer breaks. Half an hour after lunch, the WM is in their office preparing for an off-site meeting with an important customer, when they see Worker X reverse into a pallet of finished product that was on the urgent despatch list. The WM is angered by this, especially because they are in a rush to get to their meeting. They phone the CEO and ask them to speak to Worker X. The WM quickly explains to the CEO what has been happening recently, the suspicions raised by other workers, and about the incident that has just occurred. The CEO does not want to hear excuses when they speak to Worker X. The CEO immediately accuses Worker X of being drunk at work and says that this will not be tolerated. They issue a warning to Worker X and state that if anything like this happens again, they will be immediately dismissed from their job. Before Worker X can say anything, the CEO tells them to go home and sober up! Involvement of specialists The PM has taken some noise readings at various points within the tableting area, as part of a risk assessment. This has never been done before. Noise levels have been found to be between 84 dB(A) and 86dB(A). Because of these findings the human resources (HR) manager engaged a consultant from Healthy and Safe (HaS) to carry out more detailed noise measurements and advise on noise reduction methods and a health surveillance programme. Based on HaS's recommendations, the HR manager is introducing audiometry testing for all existing workers in the tableting department and any new workers going forward. Workers remain concerned about the levels of dust, so Nutripex have decided to engage an Occupational Hygienist (OH) to help review exposure of workers to vitamin C powder and other raw materials. Some initial results of the OH's work are given in supporting document 1. In the last couple of weeks there have been frequent alarms on the LEV control panel. As a result of this, the PM arranged for a thorough inspection and test (TExT) of the LEV, which has just been completed by a competent external contractor, AirTest. The PM is looking through the results and recommendations in AirTest's report. One of the recommendations is to change the current design of the LEV at the charging point where raw materials are added to the mixing machines. The PM and HR manager have now met with the OH to go through the dust exposure measurements and decide what to do next. The OH agrees that the LEV design change recommended by AirTest would be helpful, but understands that this will take some time. In the meantime, the OH is concerned about the levels of dust exposure and recommends that workers handling vitamin C powder should wear tight-fitting respiratory protective equipment (RPE). The OH has made recommendations about the specific type of RPE and the PM says that they will help ensure that it is used, just as soon as it arrives from the supplier. page 4 of 9 Supporting Documents 1. Information about workers' exposure to vitamin C 2. Email about Worker X 3. Section of LEV system in tableting department 4. Current and recommended LEV designs at mixing vessel charging point 5. Health surveillance findings sk 3: LEV effectiveness According to HSG 258 (A guide to local exhaust ventilation) a local exhaust ventilation (LEV) thorough examination and test (TEXT) involves three stages. The first of these three stages is a 'visual and structural examination' of the LEV. (a) (i) Based on the scenario only, what indicators suggest that there may be a problem with the LEV system? (8) (ii) What else should those carrying out the TEXT do during this first stage? (12) The second stage of the LEV TExT is a review of the technical performance; this includes measuring. In the diagram in supporting document 3 , three possible locations (marked X,Y and Z ) for measuring duct velocity are shown. (b) (i) What features make a suitable location for measuring duct velocity? (4) (ii) Discuss the suitability of EACH of these test locations when measuring duct velocity. Note: You must discuss locations X,Y and Z in your answer. (c) Identify FOUR measurements, other than duct velocity, that could be made during the second stage of the LEV TEXT. (4) One of the recommendations made in the recent LEV TEXT report is to change the current design of the LEV at the mixing vessel charging points. The current and recommended designs are shown in supporting document 4. (d) Explain how the recommended new LEV design, shown in figure 2 of supporting document 4 , will help to reduce the exposure of workers when working at the mixing vessel charging point. (18) Note: You should support your answer, where applicable, using relevant information from the scenario and the relevant supporting document. Supporting document 1 Information relevant to workers' exposure to vitamin C powder SECTION 1 Fixed place (static) measurements next to charging point of Mixing Vessel E All measurements taken over a 3-hour period from 09:00 - 12:00 on each day Weekly Production Schedule for Mixing Vessel E SECTION 2 Personal exposure dust measurements for workers at Mixing Vessel E charging point Supnnrtina document 1: Information relevant to workers' exposure to vitamin C powder Particle Size Distrihution Data for vitamin C nowder Supporting document 2 E-mail exchange in relation to Worker X From: CEO Sent: 26 April 2023 13:10 To: HR Manager Subject: Worker X and alcohol problem Good afternoon, Just had to deal with an incident involving Worker X. It seemed they were drunk while driving the FLT and reversed it into a pallet of product, which is now all damaged. I have sent them home and told them if it happens again, it would be straight to dismissal. The Warehouse Manager tells me some of the team have had suspicions about their behaviour for a while. Need to sort this before it happens again. Please can you get a policy issued and just set up arrangements for alcohol testing for Worker X and the rest of the Warehouse team. Regards CEO From: HR Manager Sent: 26 April 2023 14:00 To: CEO Subject: Private and Confidential Good afternoon. Thank you for your e-mail outlining this serious incident and the actions you have taken to date. I request we meet urgently to discuss the handling of this particular matter concerning Worker x. In relation to your request regarding an alcohol policy, this is not just something that can be issued. However, I will give this some thought and come back to you tomorrow with a proposal on how such a policy could be developed. Introducing alcohol testing is a complex matter with a range of contractual, practical and legal considerations, which means I cannot just set this up. I can outline these considerations to you when we meet. Regards HR Manager Snporting document 2]: E-mail exchange in relation to Worker A Supporting document 3 Section of LEV system in tableting department Duct diameters: at X30cm at Y50cm at Z50cm Supporting document 3: Section of LEV System - 1 page 1 of 4 Supporting document 4 Current and recommended LEV designs at mixing vessel charging point Figure 1 - current design Figure 2 - recommended design Source: Controlling airborne contaminants at work: a guide to local exhaust ventilation (LEV), HSG258, HSE Books Controlling airborne contaminants at work: A guide to local exhaust ventilation (LEV) HSG258 (hse.gov.uk) Supporting document 5 Health surveillance findings Name: Worker Y Date of birth: 23/02/1974 Gendar. M Malo Healthy and Safe Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started