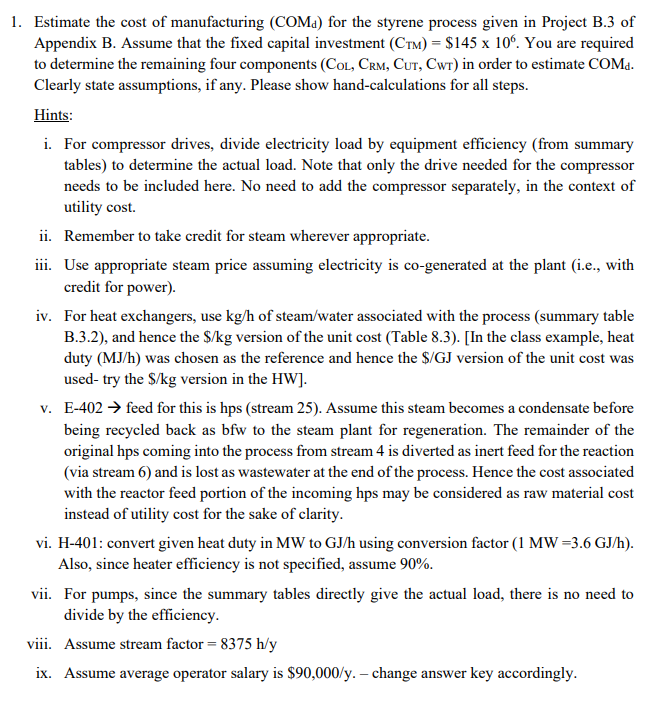

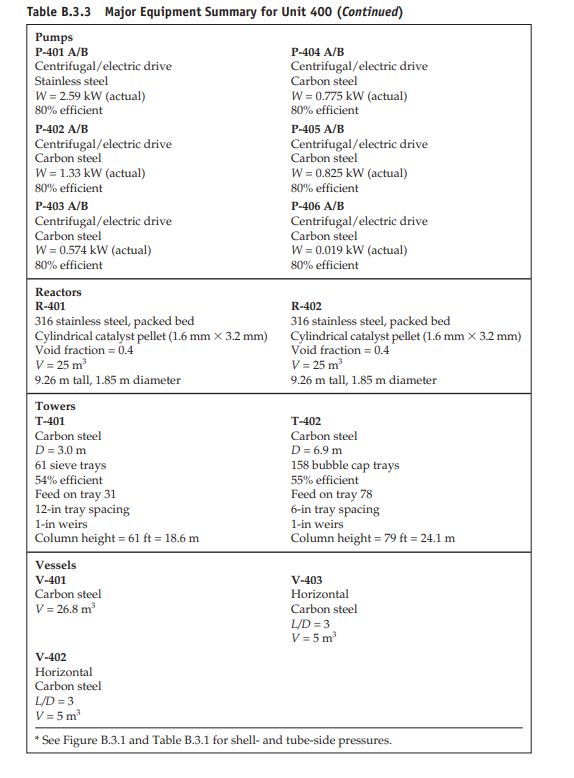

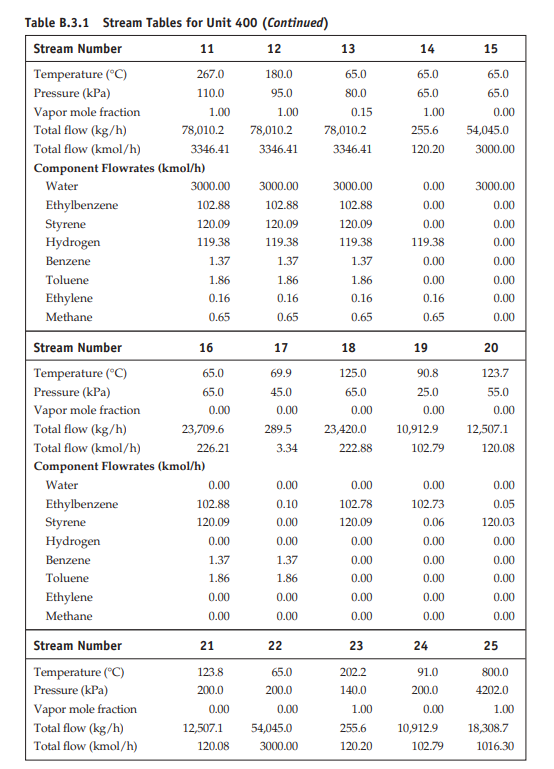

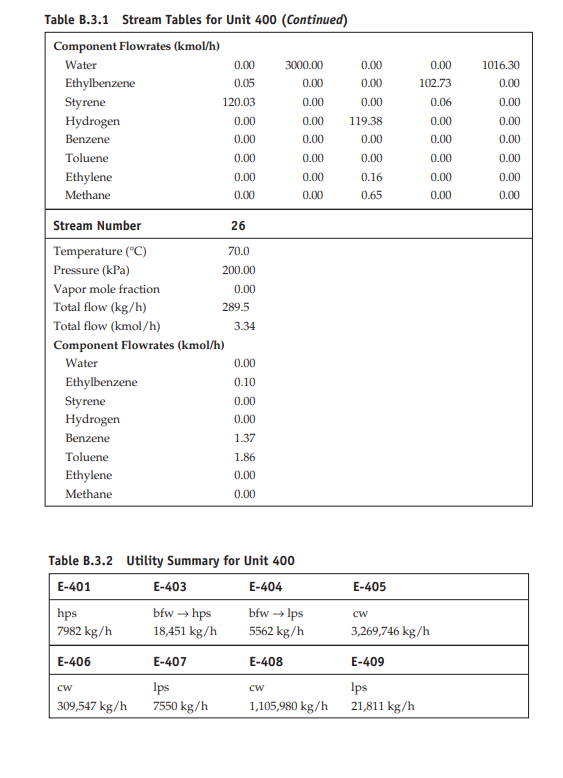

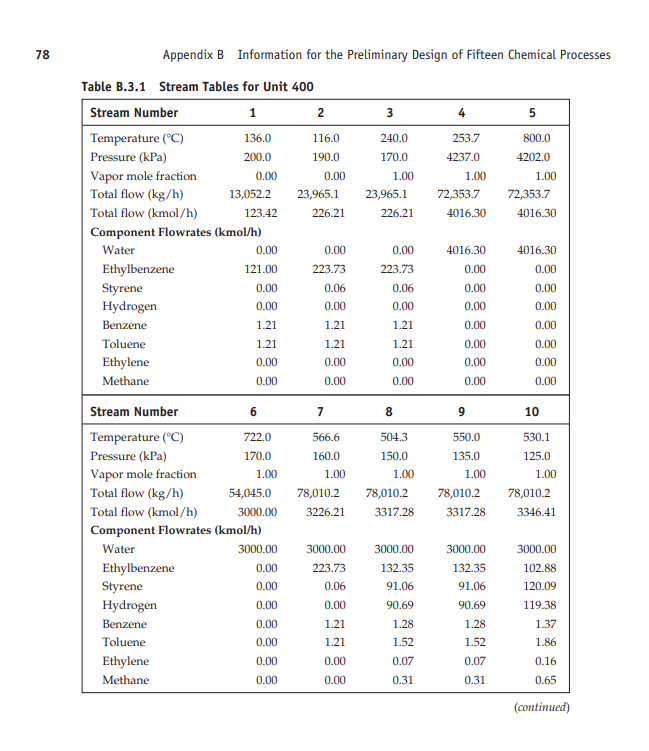

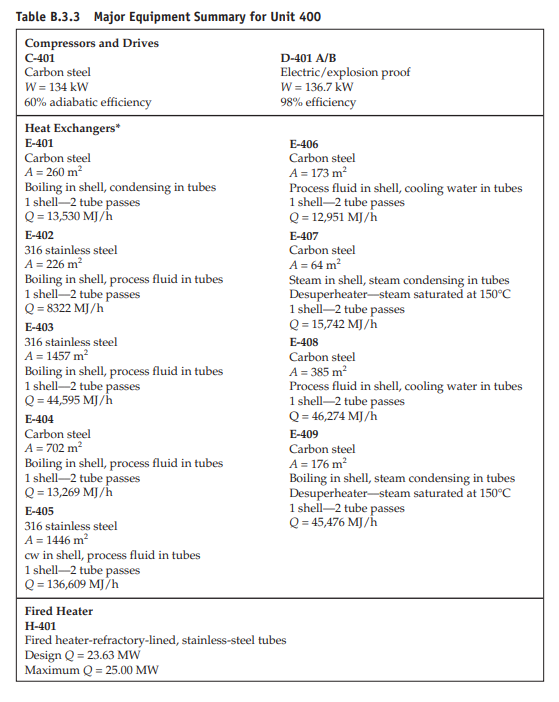

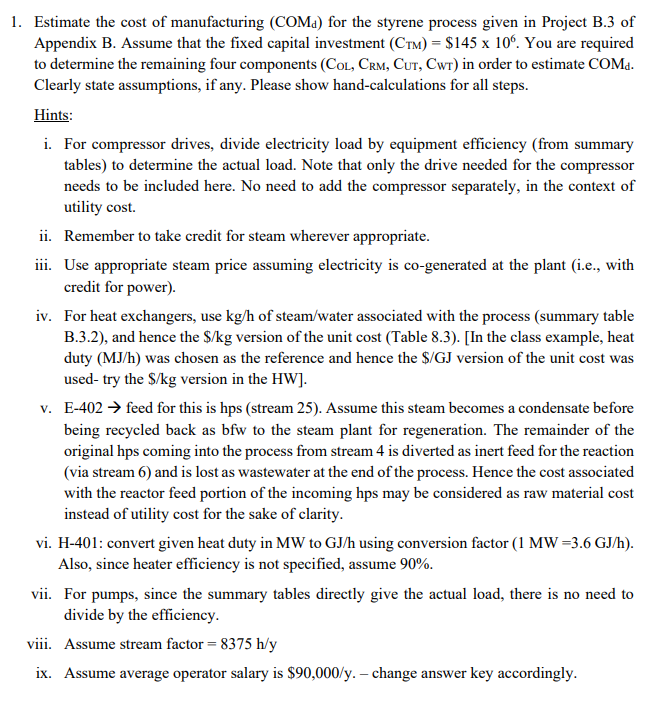

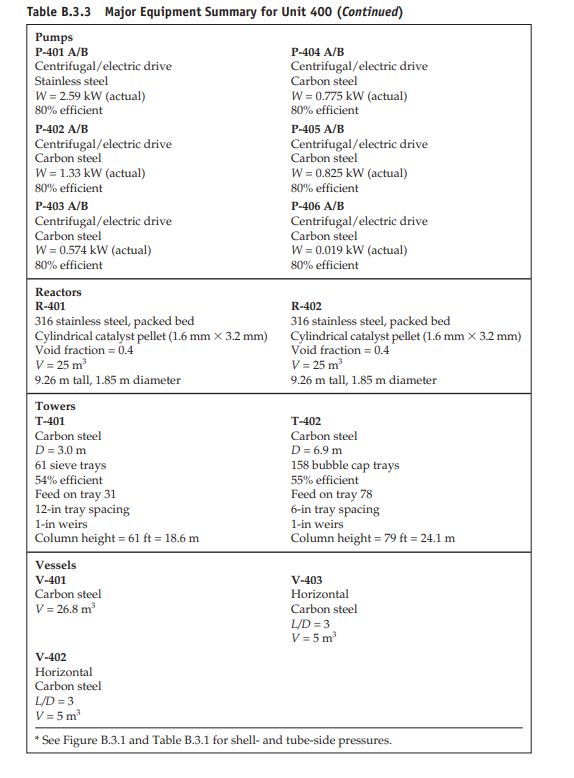

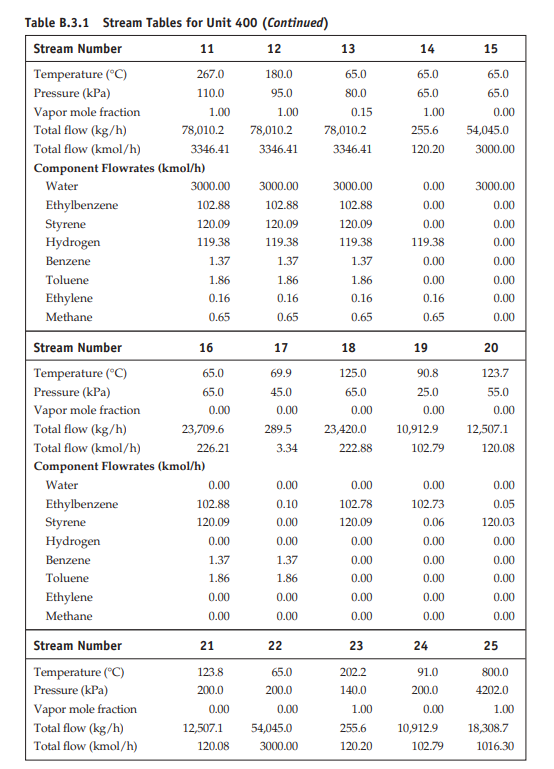

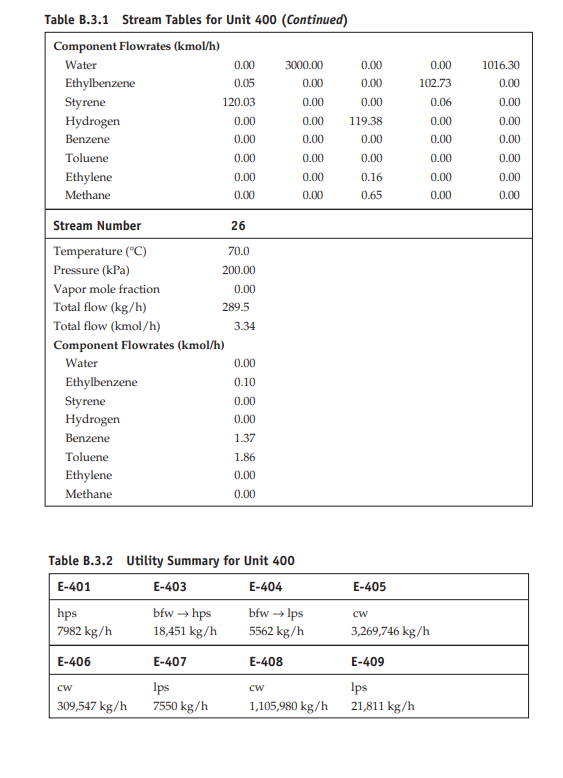

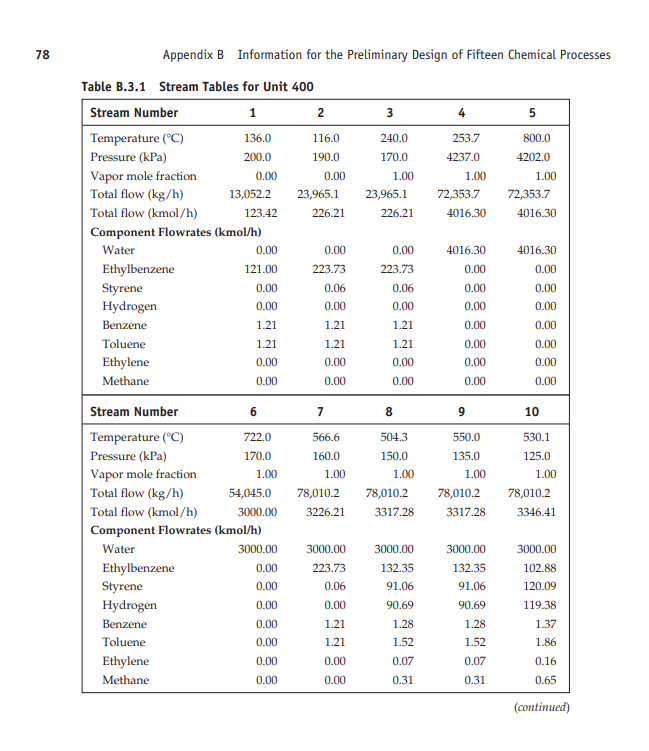

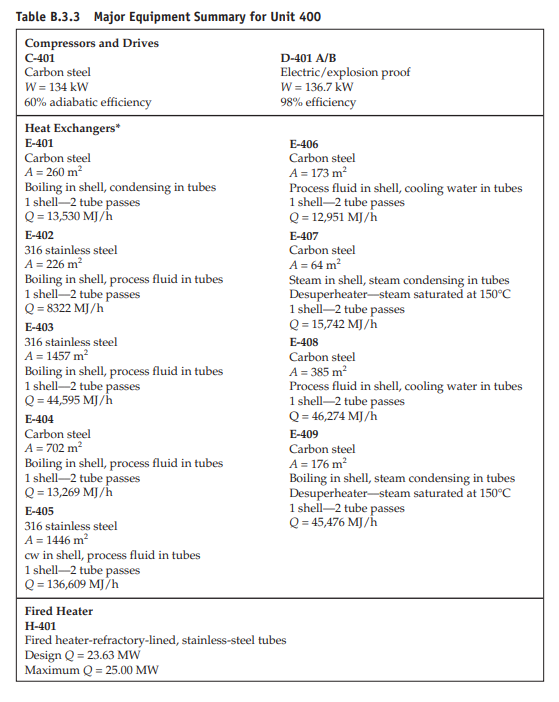

Estimate the cost of manufacturing (COMd) for the styrene process given in Project B.3 of Appendix B. Assume that the fixed capital investment (CTM)=$145106. You are required to determine the remaining four components ( COL,CRM,CUTU,CWTWT) in order to estimate COMd. Clearly state assumptions, if any. Please show hand-calculations for all steps. Hints: i. For compressor drives, divide electricity load by equipment efficiency (from summary tables) to determine the actual load. Note that only the drive needed for the compressor needs to be included here. No need to add the compressor separately, in the context of utility cost. ii. Remember to take credit for steam wherever appropriate. iii. Use appropriate steam price assuming electricity is co-generated at the plant (i.e., with credit for power). iv. For heat exchangers, use kg/h of steam/water associated with the process (summary table B.3.2), and hence the $/kg version of the unit cost (Table 8.3). [In the class example, heat duty (MJ/h) was chosen as the reference and hence the $/GJ version of the unit cost was used- try the $/kg version in the HW. v. E-402 feed for this is hps (stream 25). Assume this steam becomes a condensate before being recycled back as bfw to the steam plant for regeneration. The remainder of the original hps coming into the process from stream 4 is diverted as inert feed for the reaction (via stream 6) and is lost as wastewater at the end of the process. Hence the cost associated with the reactor feed portion of the incoming hps may be considered as raw material cost instead of utility cost for the sake of clarity. vi. H-401: convert given heat duty in MW to GJ/h using conversion factor (1 MW=3.6GJ/h). Also, since heater efficiency is not specified, assume 90%. vii. For pumps, since the summary tables directly give the actual load, there is no need to divide by the efficiency. viii. Assume stream factor =8375h/y ix. Assume average operator salary is $90,000/y. - change answer key accordingly. Table B.3.3 Major Equipment Summary for Unit 400 (Continued) * See Figure B.3.1 and Table B.3.1 for shell- and tube-side pressures. Table B.3.1 Stream Tables for Unit 400 (Continued) Tahle R. 2.1 Stream Tahles for llnit 4 (Continued) Table B.3.2 Utility Summary for Unit 400 Appendix B Information for the Preliminary Design of Fifteen Chemical Processes Table B.3.3 Maior Eauioment Summarv for Unit 400 1 shell -2 tube passes Q=136,609MJ/h Estimate the cost of manufacturing (COMd) for the styrene process given in Project B.3 of Appendix B. Assume that the fixed capital investment (CTM)=$145106. You are required to determine the remaining four components ( COL,CRM,CUTU,CWTWT) in order to estimate COMd. Clearly state assumptions, if any. Please show hand-calculations for all steps. Hints: i. For compressor drives, divide electricity load by equipment efficiency (from summary tables) to determine the actual load. Note that only the drive needed for the compressor needs to be included here. No need to add the compressor separately, in the context of utility cost. ii. Remember to take credit for steam wherever appropriate. iii. Use appropriate steam price assuming electricity is co-generated at the plant (i.e., with credit for power). iv. For heat exchangers, use kg/h of steam/water associated with the process (summary table B.3.2), and hence the $/kg version of the unit cost (Table 8.3). [In the class example, heat duty (MJ/h) was chosen as the reference and hence the $/GJ version of the unit cost was used- try the $/kg version in the HW. v. E-402 feed for this is hps (stream 25). Assume this steam becomes a condensate before being recycled back as bfw to the steam plant for regeneration. The remainder of the original hps coming into the process from stream 4 is diverted as inert feed for the reaction (via stream 6) and is lost as wastewater at the end of the process. Hence the cost associated with the reactor feed portion of the incoming hps may be considered as raw material cost instead of utility cost for the sake of clarity. vi. H-401: convert given heat duty in MW to GJ/h using conversion factor (1 MW=3.6GJ/h). Also, since heater efficiency is not specified, assume 90%. vii. For pumps, since the summary tables directly give the actual load, there is no need to divide by the efficiency. viii. Assume stream factor =8375h/y ix. Assume average operator salary is $90,000/y. - change answer key accordingly. Table B.3.3 Major Equipment Summary for Unit 400 (Continued) * See Figure B.3.1 and Table B.3.1 for shell- and tube-side pressures. Table B.3.1 Stream Tables for Unit 400 (Continued) Tahle R. 2.1 Stream Tahles for llnit 4 (Continued) Table B.3.2 Utility Summary for Unit 400 Appendix B Information for the Preliminary Design of Fifteen Chemical Processes Table B.3.3 Maior Eauioment Summarv for Unit 400 1 shell -2 tube passes Q=136,609MJ/h