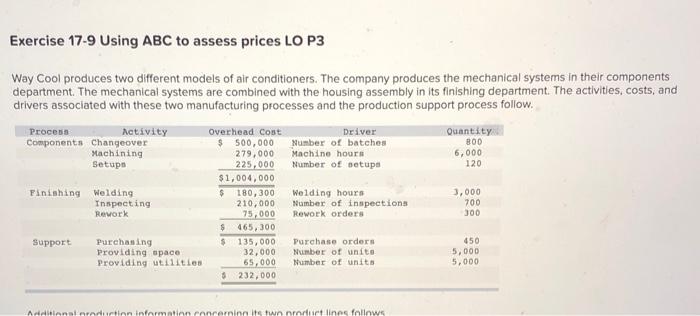

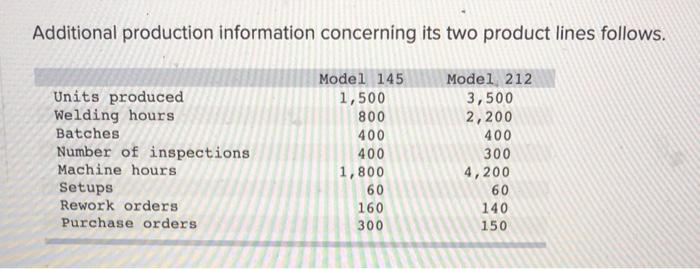

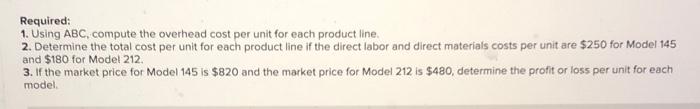

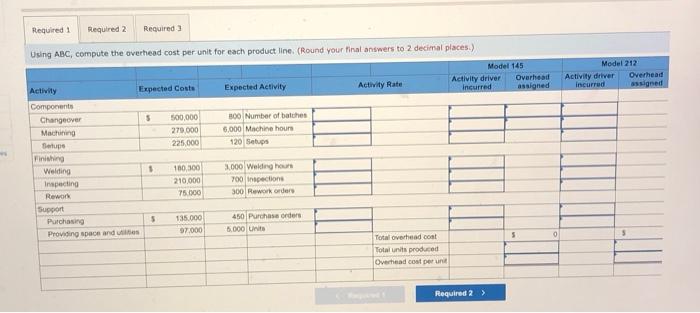

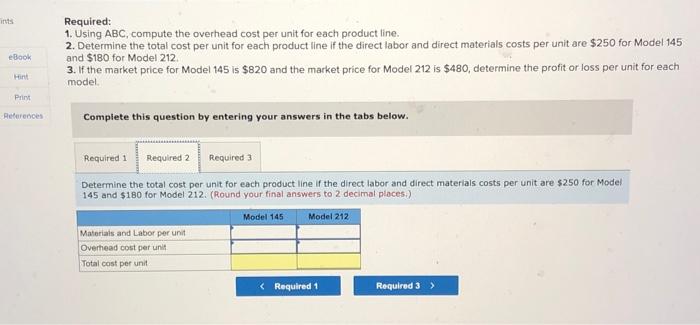

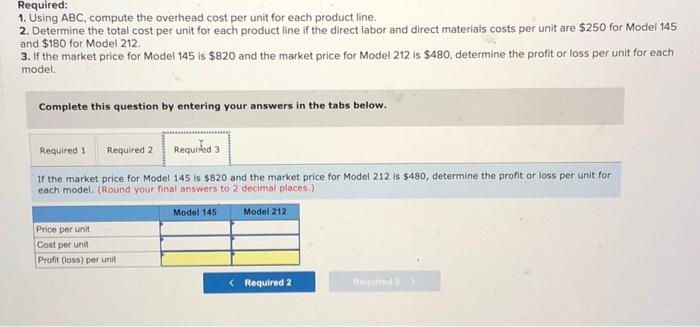

Exercise 17-9 Using ABC to assess prices LO P3 Way Cool produces two different models of air conditioners. The company produces the mechanical systems in their components department . The mechanical systems are combined with the housing assembly in its finishing department. The activities, costs, and drivers associated with these two manufacturing processes and the production support process follow. Process Activity Components Changeover Machining Setupa Driver Number of batches Machine hours Number of setupa Quantity 800 6,000 120 Finishing Welding Inspecting Rework Overhead Cost $ 500,000 279,000 225,000 $1,004,000 $ 180,300 210,000 75,000 $ 465,300 135,000 32,000 65,000 $ 232,000 Welding hours Number of inspections Rework orders 3,000 700 300 Support Purchasing Providing space Providing utilities Purchase orders Number of unite Number of units 450 5,000 5,000 Abanslardation information concerning its twortlines follow Additional production information concerning its two product lines follows. Units produced Welding hours Batches Number of inspections Machine hours Setups Rework orders Purchase orders Model 145 1,500 800 400 400 1,800 60 160 300 Model 212 3,500 2,200 400 300 4,200 60 140 150 Required: 1. Using ABC, compute the overhead cost per unit for each product line 2. Determine the total cost per unit for each product line if the direct labor and direct materials costs per unit are $250 for Model 145 and $180 for Model 212. 3. If the market price for Model 145 is $820 and the market price for Model 212 is $480, determine the profit or loss per unit for each model Required 1 Required 2 Required Using ABC, compute the overhead cost per unit for each product line. (Round your final answers to 2 decimal places) Model 145 Activity driver Overhead incurred assigned Model 212 Activity driver Overhead incurred Expected Costa Expected Activity Activity Rate 5 500,000 279.000 225.000 300 Number of batches 6,000 Machine hour 120 Setups Activity Components Changeover Machting Batups Finishing Welding Inspecting Rework Support Purchasing Providing space and 1 100,300 210 000 75.000 3.000 Welding hour 700 Inspections 300 Rekorder 5 135.000 97.000 450 Purchase orders 6,000 units 5 Total Overhead coat Total units produced Overhead cost per un Required 2 > int Required: 1. Using ABC, compute the overhead cost per unit for each product line. 2. Determine the total cost per unit for each product line if the direct labor and direct materials costs per unit are $250 for Model 145 and $180 for Model 212 3. If the market price for Model 145 is $820 and the market price for Model 212 is $480, determine the profit or loss per unit for each model eBook Hint Print References Complete this question by entering your answers in the tabs below. Required 1 Required 2 Required 3 Determine the total cost per unit for each product line if the direct labor and direct materials costs per unit are $250 for Model 145 and $180 for Model 212. (Round your final answers to 2 decimal places.) Model 145 Model 212 Materials and Labor per unit Overhead cost per unit Total cost per unit Required: 1. Using ABC, compute the overhead cost per unit for each product line. 2. Determine the total cost per unit for each product line if the direct labor and direct materials costs per unit are $250 for Model 145 and $180 for Model 212 3. If the market price for Model 145 is $820 and the market price for Model 212 is $480, determine the profit or loss per unit for each model. Complete this question by entering your answers in the tabs below. Required 1 Required 2 Requited 3 If the market price for Model 145 is $820 and the market price for Model 212 is $480, determine the profit or loss per unit for each model. (Round your final answers to 2 decimal places.) Model 145 Model 212 Price per unit Cost per unit Profit (loss) per unit