Question

Feedback 1. What is the potential total contribution margin? How much time will it take to make all of the products that can be sold?

Feedback

1. What is the potential total contribution margin?

How much time will it take to make all of the products that can be sold?

Does the time needed in any department exceed the time available in that department?

Review what you have learned in the chapter.

What is the contribution per unit of scarce resource?

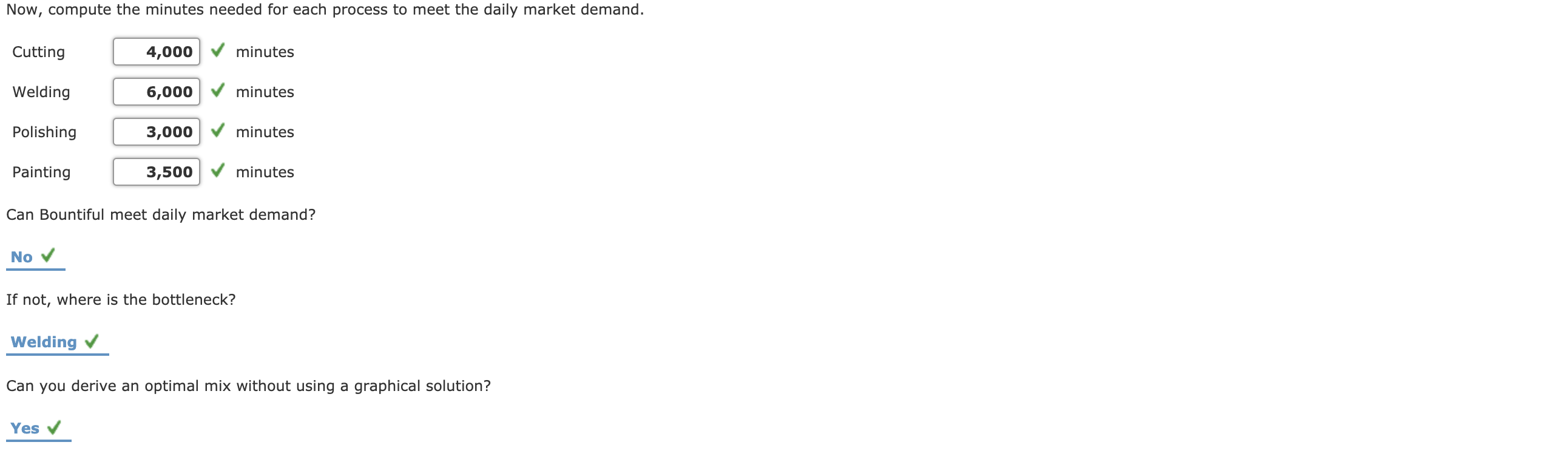

2. The objective function can be expressed mathematically by multiplying the unit contribution margin by the units to be produced for each product and then summing over all products. An internal constraint is a limiting factor found within the firm. External constraints are limiting factors imposed on the firm from external sources. Nonnegativity constraints simply reflect the reality that negative quantities cannot be produced and are usually included in the constraint set. Constraints are expressed as inequalities, where the amount of scarce resource used per unit of product is multiplied by the units to be produced for each product and summed. This is compared to the amount of the resource available.

Four steps are followed in solving the problem graphically:

- Graph each constraint.

- Identify the feasible set of solutions. A feasible solution is one that satisfies the constraints in the linear programming model. In this case, look for the inmost shape on the graph.

- Identify all corner-point values in the feasible set. Corner points are the corners of the area on the graph that satisfies the constraints. You may have to use algebra to solve simultaneous equations to pinpoint where two of the constraint lines meet.

- Select the corner point that yields the largest value for the objective function. Plug the x and y values for each corner point into the objective equation. Which one results in the highest value?

3. The major binding constraint is the drummer. The time buffer is the inventory needed to keep the constrained resource busy for a specified time interval. Ropes are actions taken to tie the rate at which material is released into the plant (at the first operation) to the production rate of the constrained resource.

4. If welding time is reduced, how many more units can be produced? Would this have an impact on profitability?

Review what you have learned about the five-step method for improving performance in the chapter.

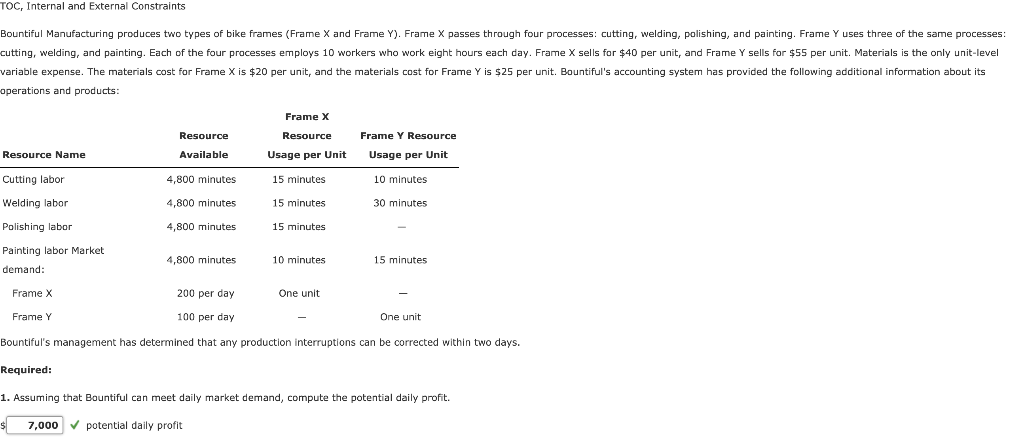

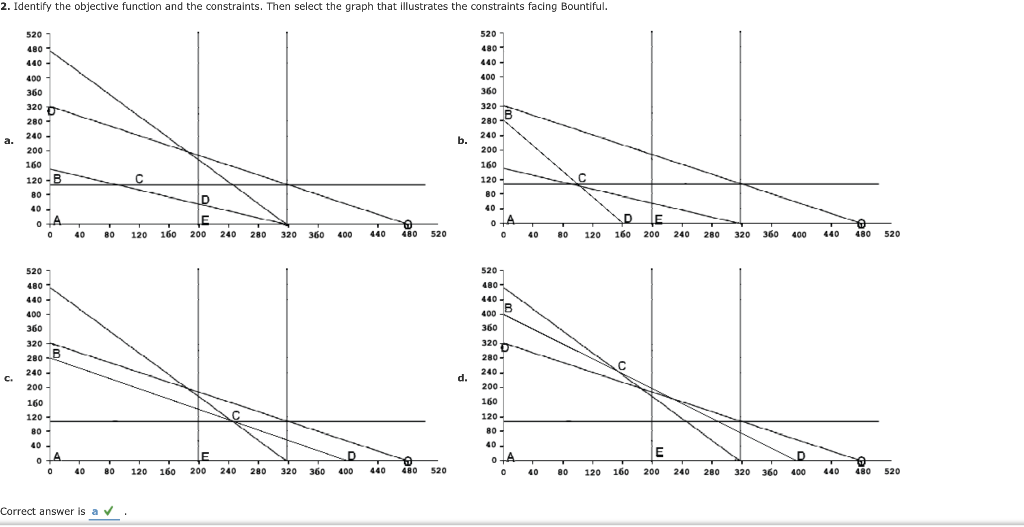

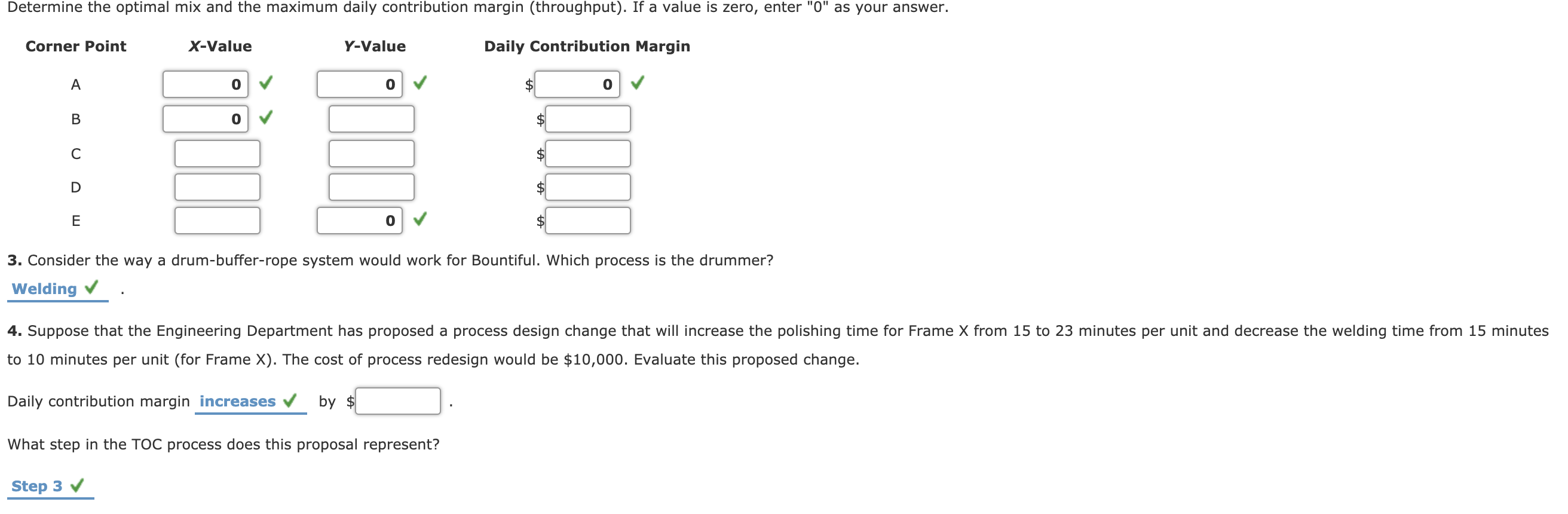

TOC, Internal and External Constraints Bountiful Manufacturing produces two types of bike frames (Frame X and Frame Y). Frame X passes through four processes: cutting, welding, polishing, and painting. Frame Y uses three of the same processes: cutting, welding, and painting. Each of the four processes employs 10 workers who work eight hours each day. Frame X sells for $40 per unit, and Frame Y sells for $55 per unit. Materials is the only unit-level variable expense. The materials cost for Frame X is $20 per unit, and the materials cost for Frame Y is $25 per unit. Bountiful's accounting system has provided the following additional information about its operations and products: Frame X Resource Frame Y Resource Resource Available Resource Name Usage per Unit Usage per Unit Cutting labor 4,800 minutes 15 minutes 10 minutes 4,800 minutes 15 minutes 30 minutes Welding labor Polishing labor 4,800 minutes 15 minutes Painting labor Market demand: 4,800 minutes 10 minutes 15 minutes Framex 200 per day One unit Frame Y 100 per day One unit Bountiful's management has determined that any production interruptions can be corrected within two days. Required: 1. Assuming that Bountiful can meet daily market demand, compute the potential daily profit. $ 7,000 potential daily profit Now, compute the minutes needed for each process to meet the daily market demand. Cutting 4,000 minutes Welding 6,000 minutes Polishing 3,000 minutes Painting 3,500 minutes Can Bountiful meet daily market demand? No If not, where is the bottleneck? Welding Can you derive an optimal mix without using a graphical solution? Yes e objective function and the constraints Then select the graph at illustrates the constraints facing Bountiful. 520 b at 40 120 & 10 80 120 60 240 280 320 1 I d. 10 80 120 200 240 280 320 360 400 440 4080 120 160 200 240 280 320 31 80520 Correct answer is a Determine the optimal mix and the maximum daily contribution margin (throughput). If a value is zero, enter "0" as your answer. Corner Point X-Value Y-Value Daily Contribution Margin A 0 0 $ 0 B 0 C D E 0 3. Consider the way a drum-buffer-rope system would work for Bountiful. Which process is the drummer? Welding 4. Suppose that the Engineering Department has proposed a process design change that will increase the polishing time for Frame X from 15 to 23 minutes per unit and decrease the welding time from 15 minutes to 10 minutes per unit (for Frame X). The cost of process redesign would be $10,000. Evaluate this proposed change. Daily contribution margin increases by $ What step in the TOC process does this proposal represent? Step 3Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started