Answered step by step

Verified Expert Solution

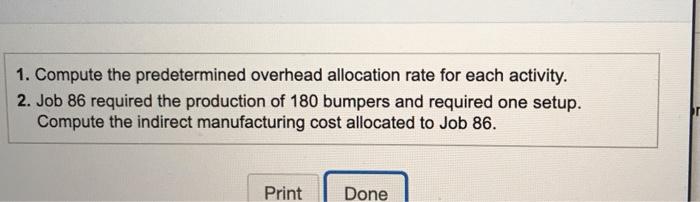

Question

1 Approved Answer

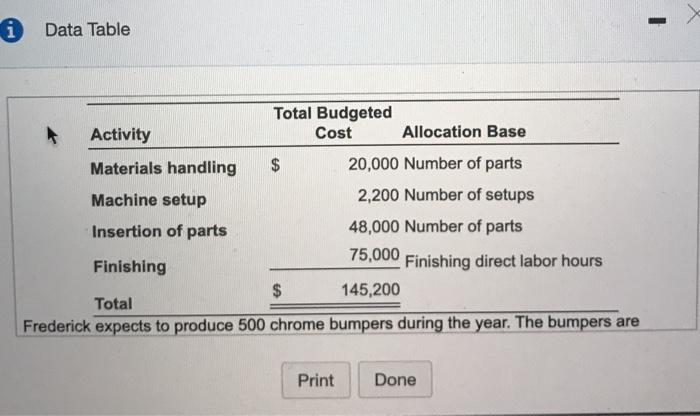

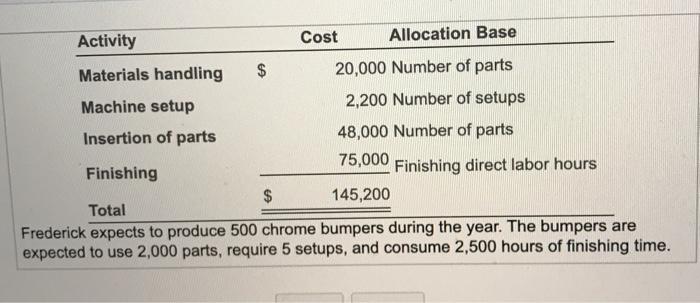

Frederick, Inc. uses activity based costing to account for its chrome bumper manufacturing process Company managers have densified four manufacturing activities manting machine setup, Insertion

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started