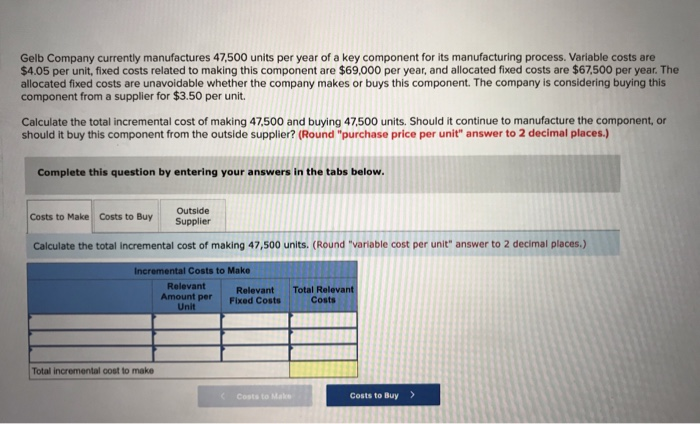

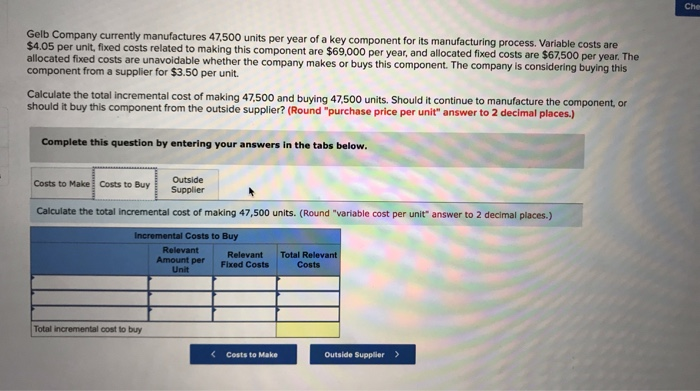

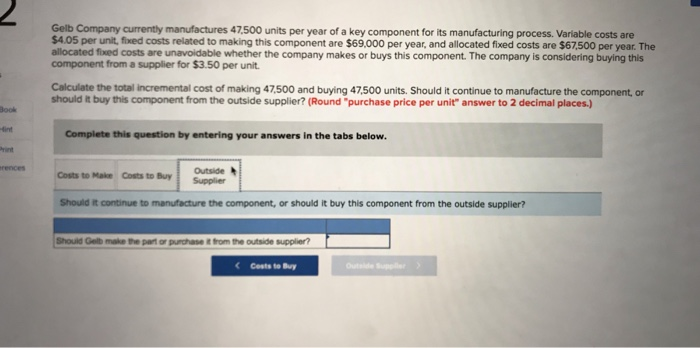

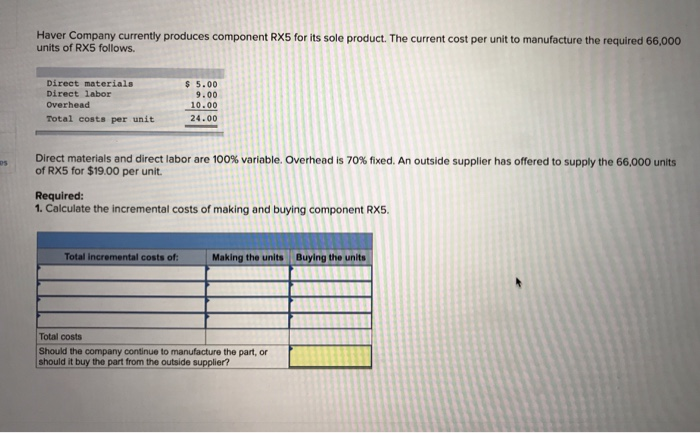

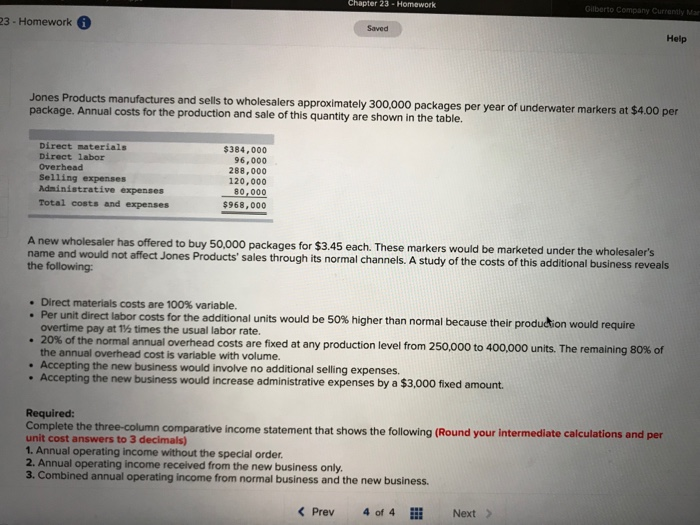

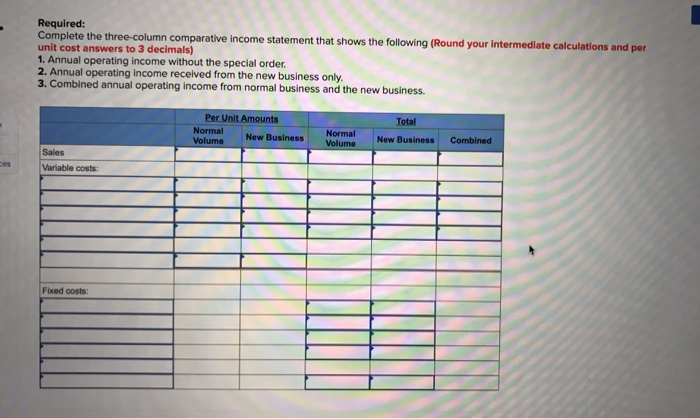

Gelb Company currently manufactures 47,500 units per year of a key component for its manufacturing process. Variable costs are $4.05 per unit, fixed costs related to making this component are $69,000 per year, and allocated fixed costs are $67,500 per year. The allocated fixed costs are unavoidable whether the company makes or buys this component. The company is considering buying this component from a supplier for $3.50 per unit. Calculate the total incremental cost of making 47,500 and buying 47,500 units. Should it continue to manufacture the component, or should it buy this component from the outside supplier? (Round "purchase price per unit" answer to 2 decimal places.) Complete this question by entering your answers in the tabs below Costs to Buy Costs to Make Supplier Calculate the total incremental cost of making 47,500 units. (Round "variable cost per unit" answer to 2 decimal places.) l Costs to Make Relevant Relevant Amount per Fixed Costs Total Relevant Costs Total incremental cost to make Costs to Buy> Costs to Make Che Company currently manufactures 47500 units per year of a key component for its manufacturing process. Variable costs are 05 per unit, fixed costs related to making this component are $69,000 per year, and allocated fixed costs are $67,500 per year. The allocated fixed costs are un avoidable whether the company makes or buys this component. The company is considering buying this component from a supplier for $3.50 per unit. Calculate the total incremental cost of making 47.500 and buying 47,500 units. Should it continue to manufacture the component, or should it buy this component from the outside supplier? (Round "purchase price per unit" answer to 2 decimal places.) Complete this question by entering your answers in the tabs below Outside Supplier Costs to Make Costs to Buy Calculate the total incremental cost of making 47,500 units. (Round "variable cost per unit" answer to 2 decimal places.) al Costs to Buy Amount per Relevant Total Relevant Costs Total incremental cost to buy Outside Supplier > Costs to Make Gelb Company currently manufactures 47,500 units per year of a key component for its manufacturing process. Variable costs are $4.05 per unit, fixed costs related to making this component are $69,000 per year, and allocated fixed costs are $67,500 per year. The allocated fixed costs are unavoidable whether the company makes or buys this component. The company is considering buying this component from a supplier for $3.50 per unit. Calculate the total incremental cost of making 47,500 and buying 47500 units. Should it continue to manufacture the component, or should should it buy this component from the outside supplier? (Round "purchase price per unit" answer to 2 decimal places.) Book tint Complete this question by entering your answers in the tabs below. rint Costs to Make Costs to BuyOutside Supplier Should it continue to manufacture the component, or should it buy this component from the outside supplier Shouid Gelb make the part or purchase it from the outside supplier? C Costs to Buy Haver Company currently produces component RX5 for its sole product. The current cost per unit to manufacture the required 66,000 units of RX5 follows Direct materials Direct labor Overhead $ 5.00 9.00 10.00 24.00 Total costs per unit Direct materials and direct labor are 100% variable. Overhead is 70% fixed. An outside supplier has offered to supply the 66,000 units of RX5 for $19.00 per unit Required 1. Calculate the incremental costs of making and buying component RX5 Total incremental costs of: Making the units Buying the units Total costs Should the company continue to manufacture the part, or should it buy the part from the outside supplier? chapter 23 Homework urrenily 23- Homework 6 Saved Help manufactures and sells to wholesalers approximately 300.000 packages per year of underwater package. Annual costs for the production and sale of this quantity are shown in the table Direct materials Direct labor Overhead Selling expenses Administrative expenses Total costs and expenses $384,000 96,000 288,000 120,000 80,000 $968,000 offered to buy 50,000 packages for $3.45 each. These markers would be marketed under the wholesaler's name and would not affect Jones Products' sales through its normal channels. A study of the costs of this additional business reveals the following: Direct materials costs are 100% variable. Per unit direct labor costs for the additional units would be 50% higher than normal because their produ on would require overtime pay at 1/2 times the usual labor rate. 20% of the normal annual overhead costs are fixed at any production level from 250,000 to 400,000 units. The remaining 80% of the annual overhead cost is variable with volume. Accepting the new business would involve no additional selling expenses. Accepting the new business would increase administrative expenses by a $3,000 fixed amount. Required Complete the three-column comparative income statement that shows the following (Round your intermediate calculations and per unit cost answers to 3 decimals) 1. Annual operating income without the special order 2. Annual operating income received from the new business only 3. Combined annual operating income from normal business and the new business Next >