Answered step by step

Verified Expert Solution

Question

1 Approved Answer

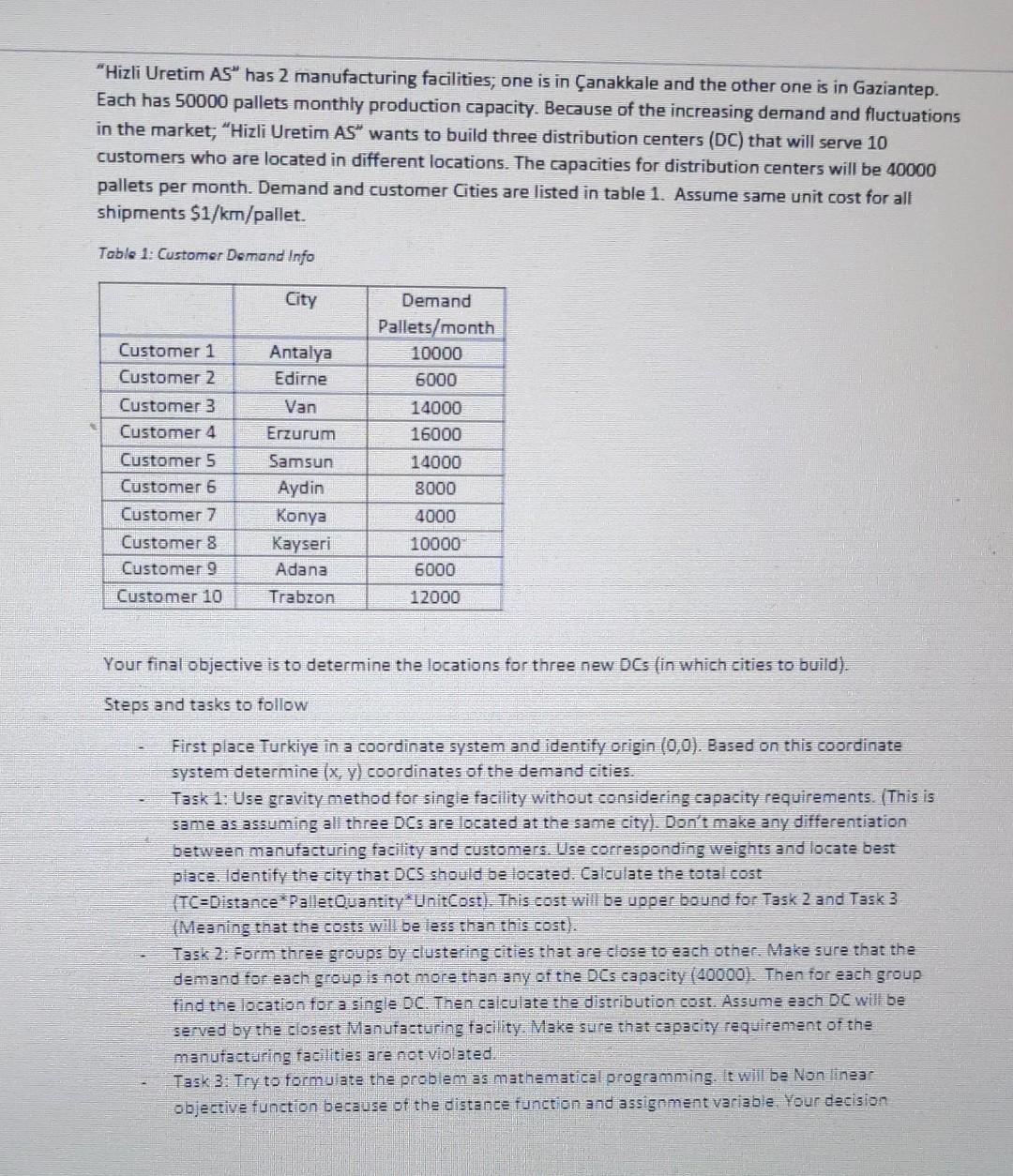

Hizli Uretim AS has 2 manufacturing facilities, one is in anakkale and the other one is in Gaziantep Each has 50000 pallets monthly production capacity.

"Hizli Uretim AS" has 2 manufacturing facilities, one is in anakkale and the other one is in Gaziantep Each has 50000 pallets monthly production capacity. Because of the increasing demand and fluctuations in the market; "Hizli Uretim AS" wants to build three distribution centers (DC) that will serve 10 customers who are located in different locations. The capacities for distribution centers will be 40000 pallets per month. Demand and customer Cities are listed in table 1. Assume same unit cost for all shipments $1/km/pallet. Table 1: Customer Demand Info City Customer 1 Customer 2 Customer 3 Customer 4 Customer 5 Customer 6 Customer 7 Customer 8 Customer 9 Customer 10 Antalya Edirne Van Erzurum Samsun Aydin Konya Kayseri Adana Trabzon Demand Pallets/month 10000 6000 14000 16000 14000 8000 4000 10000 6000 12000 Your final objective is to determine the locations for three new DCs (in which cities to build). Steps and tasks to follow First place Turkiye in a coordinate system and identify origin (0,0). Based on this coordinate system determine ix, y) coordinates of the demand cities. Task 1: Use gravity method for single facility without considering capacity requirements. (This is same as assuming all three DCs are located at the same city). Don't make any differentiation between manufacturing facility and customers. Use corresponding weights and locate best place. Identify the city that DCS should be located. Calculate the total cost TC=Distance *Pallet Quantity*UnitCost). This cost will be upper bound for Task 2 and Task 3 (Meaning that the costs will be less than this cost). Task 2: Form three groups by clustering cities that are close to each other. Make sure that the demand for each group is not more than any of the DCs capacity (40000). Then for each group find the location for a single DC. Then calculate the distribution cost. Assume esch DC will be served by the closest Manufacturing facility. Make sure that capacity requirement of the manufacturing facilities are not violated. Task 3: Try to formulate the problem as mathematical programming. It will be Non linear objective function because of the distance function and assignment variable. Your decision "Hizli Uretim AS" has 2 manufacturing facilities, one is in anakkale and the other one is in Gaziantep Each has 50000 pallets monthly production capacity. Because of the increasing demand and fluctuations in the market; "Hizli Uretim AS" wants to build three distribution centers (DC) that will serve 10 customers who are located in different locations. The capacities for distribution centers will be 40000 pallets per month. Demand and customer Cities are listed in table 1. Assume same unit cost for all shipments $1/km/pallet. Table 1: Customer Demand Info City Customer 1 Customer 2 Customer 3 Customer 4 Customer 5 Customer 6 Customer 7 Customer 8 Customer 9 Customer 10 Antalya Edirne Van Erzurum Samsun Aydin Konya Kayseri Adana Trabzon Demand Pallets/month 10000 6000 14000 16000 14000 8000 4000 10000 6000 12000 Your final objective is to determine the locations for three new DCs (in which cities to build). Steps and tasks to follow First place Turkiye in a coordinate system and identify origin (0,0). Based on this coordinate system determine ix, y) coordinates of the demand cities. Task 1: Use gravity method for single facility without considering capacity requirements. (This is same as assuming all three DCs are located at the same city). Don't make any differentiation between manufacturing facility and customers. Use corresponding weights and locate best place. Identify the city that DCS should be located. Calculate the total cost TC=Distance *Pallet Quantity*UnitCost). This cost will be upper bound for Task 2 and Task 3 (Meaning that the costs will be less than this cost). Task 2: Form three groups by clustering cities that are close to each other. Make sure that the demand for each group is not more than any of the DCs capacity (40000). Then for each group find the location for a single DC. Then calculate the distribution cost. Assume esch DC will be served by the closest Manufacturing facility. Make sure that capacity requirement of the manufacturing facilities are not violated. Task 3: Try to formulate the problem as mathematical programming. It will be Non linear objective function because of the distance function and assignment variable. Your decision

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started