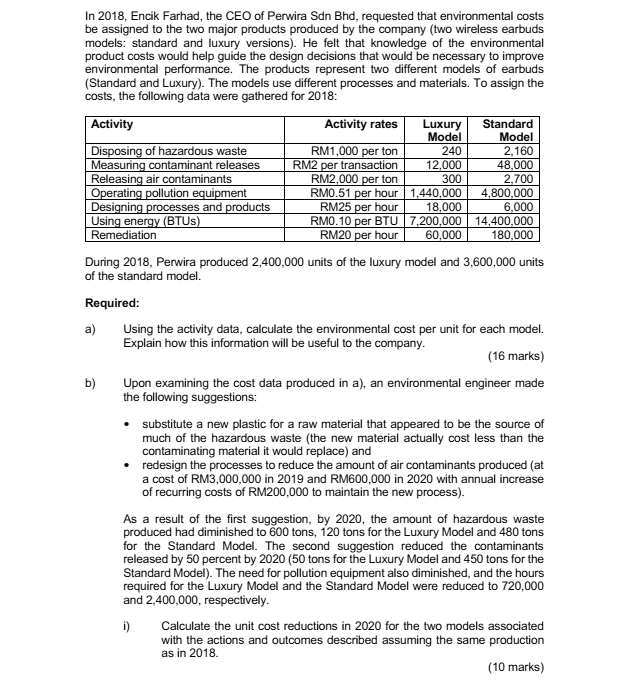

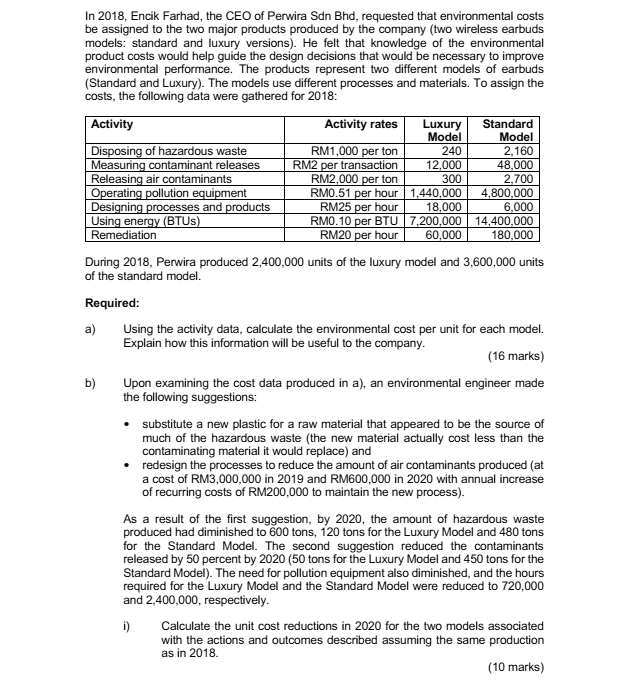

In 2018, Encik Farhad, the CEO of Perwira Sdn Bhd, requested that environmental costs be assigned to the two major products produced by the company (two wireless earbuds models: standard and luxury versions). He felt that knowledge of the environmental product costs would help guide the design decisions that would be necessary to improve environmental performance. The products represent two different models of earbuds (Standard and Luxury). The models use different processes and materials. To assign the costs, the following data were gathered for 2018: Activity Activity rates Luxury Standard Model Model Disposing of hazardous waste RM1,000 per ton 240 2,160 Measuring contaminant releases RM2 per transaction 12,000 48,000 Releasing air contaminants RM2,000 per ton 300 2,700 Operating pollution equipment RM0.51 per hour 1,440,000 4,800,000 Designing processes and products RM25 per hour 18,000 6,000 Using energy (BTU) RMO.10 per BTU 7,200,000 14,400,000 Remediation RM20 per hour 60,000 180,000 During 2018, Perwira produced 2,400,000 units of the luxury model and 3,600,000 units of the standard model. Required: a) Using the activity data, calculate the environmental cost per unit for each model. Explain how this information will be useful to the company. (16 marks) b) Upon examining the cost data produced in a), an environmental engineer made the following suggestions: substitute a new plastic for a raw material that appeared to be the source of much of the hazardous waste (the new material actually cost less than the contaminating material it would replace) and redesign the processes to reduce the amount of air contaminants produced (at a cost of RM3,000,000 in 2019 and RM600,000 in 2020 with annual increase of recurring costs of RM200,000 to maintain the new process). As a result of the first suggestion, by 2020, the amount of hazardous waste produced had diminished to 600 tons, 120 tons for the Luxury Model and 480 tons for the Standard Model. The second suggestion reduced the contaminants released by 50 percent by 2020 (50 tons for the Luxury Model and 450 tons for the Standard Model). The need for pollution equipment also diminished, and the hours required for the Luxury Model and the Standard Model were reduced to 720,000 and 2,400,000, respectively. i) Calculate the unit cost reductions in 2020 for the two models associated with the actions and outcomes described assuming the same production as in 2018 (10 marks) In 2018, Encik Farhad, the CEO of Perwira Sdn Bhd, requested that environmental costs be assigned to the two major products produced by the company (two wireless earbuds models: standard and luxury versions). He felt that knowledge of the environmental product costs would help guide the design decisions that would be necessary to improve environmental performance. The products represent two different models of earbuds (Standard and Luxury). The models use different processes and materials. To assign the costs, the following data were gathered for 2018: Activity Activity rates Luxury Standard Model Model Disposing of hazardous waste RM1,000 per ton 240 2,160 Measuring contaminant releases RM2 per transaction 12,000 48,000 Releasing air contaminants RM2,000 per ton 300 2,700 Operating pollution equipment RM0.51 per hour 1,440,000 4,800,000 Designing processes and products RM25 per hour 18,000 6,000 Using energy (BTU) RMO.10 per BTU 7,200,000 14,400,000 Remediation RM20 per hour 60,000 180,000 During 2018, Perwira produced 2,400,000 units of the luxury model and 3,600,000 units of the standard model. Required: a) Using the activity data, calculate the environmental cost per unit for each model. Explain how this information will be useful to the company. (16 marks) b) Upon examining the cost data produced in a), an environmental engineer made the following suggestions: substitute a new plastic for a raw material that appeared to be the source of much of the hazardous waste (the new material actually cost less than the contaminating material it would replace) and redesign the processes to reduce the amount of air contaminants produced (at a cost of RM3,000,000 in 2019 and RM600,000 in 2020 with annual increase of recurring costs of RM200,000 to maintain the new process). As a result of the first suggestion, by 2020, the amount of hazardous waste produced had diminished to 600 tons, 120 tons for the Luxury Model and 480 tons for the Standard Model. The second suggestion reduced the contaminants released by 50 percent by 2020 (50 tons for the Luxury Model and 450 tons for the Standard Model). The need for pollution equipment also diminished, and the hours required for the Luxury Model and the Standard Model were reduced to 720,000 and 2,400,000, respectively. i) Calculate the unit cost reductions in 2020 for the two models associated with the actions and outcomes described assuming the same production as in 2018 (10 marks)