Question

In December 2019, Jeff Small, President, and Carol Money, Controller, of Example Manufacturing (EM) were checking the budgeted figures for EMs 2020 operations. EMs parent

In December 2019, Jeff Small, President, and Carol Money, Controller, of Example Manufacturing (EM) were checking the budgeted figures for EMs 2020 operations. EMs parent company Extremist Manufacturing has established a target profit for EM of $540,000 for the coming year. Jeff and Carol wanted to make sure they could meet the target.

In early 2019, EM a large manufacturer of equipment had set up operations in Denver to manufacture two products. One was a miniature signaling device used primarily for remote operation of garage doors. These AB1 units consisted of a signal sender, about half the size of a pack of cards, and a receiver, which was a bit larger. A large manufacturer of motorized garage doors had agreed to take a minimum of 156,000 AB1 control units a year. Jeff and Carol thought a budget of 216,000 units was a reasonable manufacturing target for 2020.

EM also had designed a similar device which could be used by a household to turn on lights when arriving after dark. This unit, called CD2 was slightly more expensive to make since the receiving part was a complete plug-in device, while the AB1 receiver was a component of the garage door unit. Initially, EM expected to sell the CD2 unit primarily through mail order catalogues. Jeff and Carol projected sales of 312,000 units for 2020.

Looking at the budget, Carol indicated, Im relieved to see our projections result in a budgeted profit exceeding the target of $540,000 profit for next year expected by the parent company.

Me too, replied Jeff. But we dont have a large margin for error. Lets see what level of sales would be required to provide the parent company with its targeted profit of $540,000 for the year.

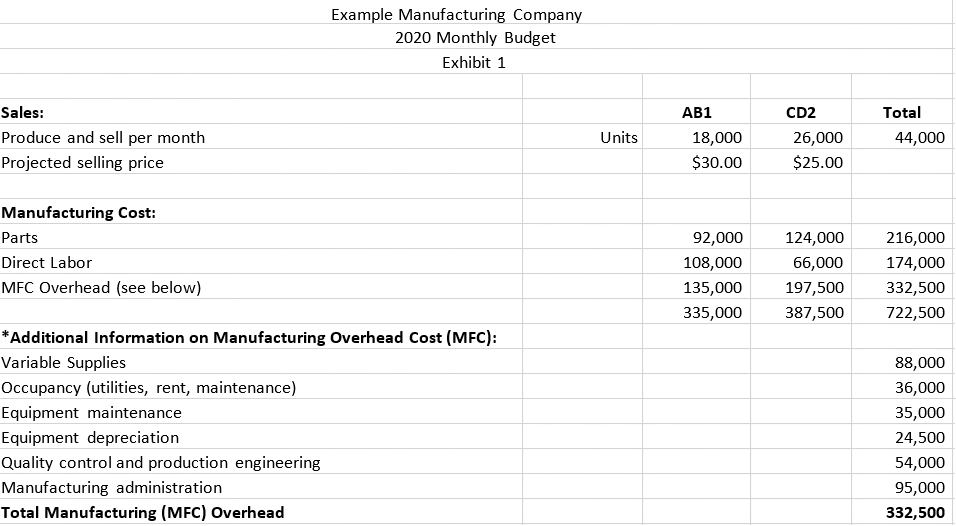

To start, Carol pulled out the monthly budgeted figures shown in Exhibit 1. In addition to these figures, selling and administrative expenses are expected to be $210,000 a month while variable manufacturing overhead supplies cost is expected to be $88,000 for the 44,000 units. She recognized the budget was only approximate since she expected changes would be made to improve efficiency and perhaps the product design. But she thought the numbers were solid enough for her to use in her analysis of what was necessary to reach the parent companys target profit. In preparing her analysis, she decided to assume parts, direct labor, and overhead supplies could be considered as variable cost since they would vary with units produced, and all the rest would be fixed within the time frame and volume range being considered.

Question:

1. What is the projected monthly net operating income (NOI) for EM for 2020 based on the budgeted figures? Create a simple traditional GAAP income statement (S COGS = GP SGA = NOI) to show your profit. (Note: profit means NOI)

2. Reorganize your budgeted monthly income statement from question 1 into a simple contribution income statement (S VC = CM FC = NOI).

3. Compute the total manufacturing cost per unit of AB1 and CD2 based on the monthly budgeted figures?

4. Compute the degree of operating leverage using your budgeted contribution margin income statement in question 2. Explain how operating leverage affects the NOI of EM.

5. If total monthly budgeted units increase by 10,500 units (4,200 units of AB1 and 6,300 units of CD2), compute the new NOI using the contribution income statement. By what percent did NOI increase or decrease from the budget? Why?

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started