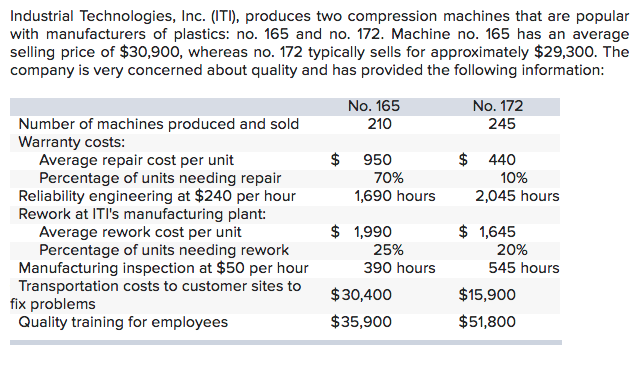

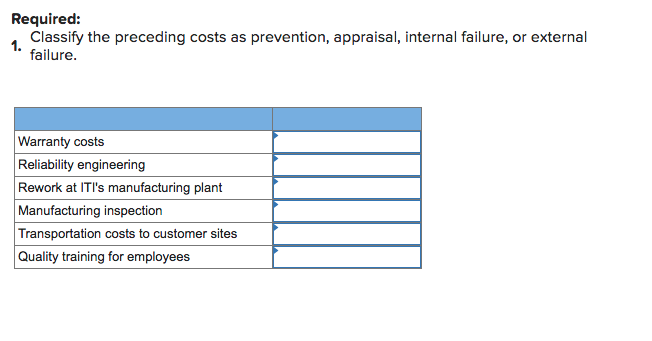

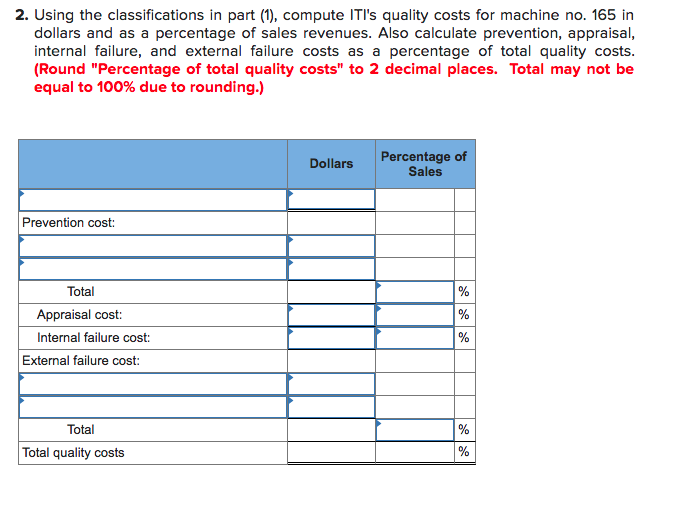

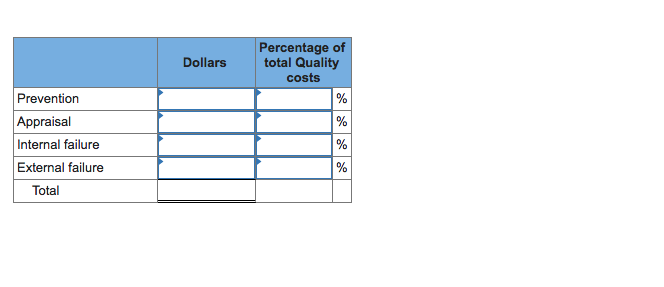

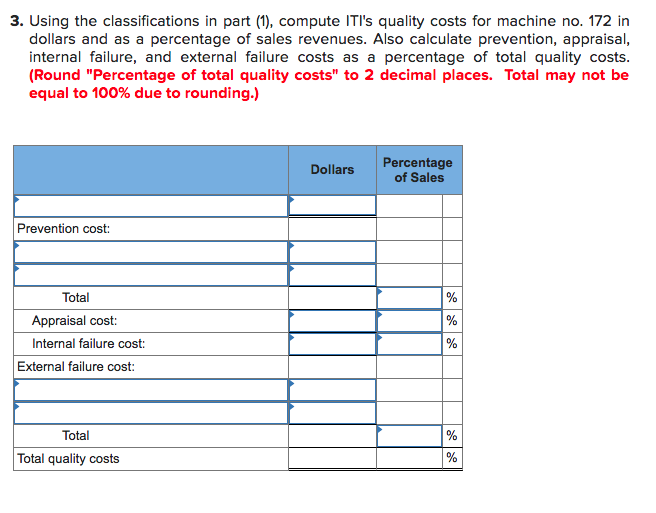

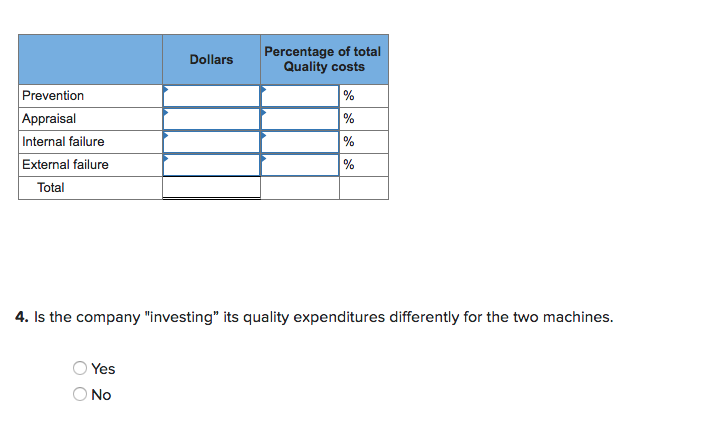

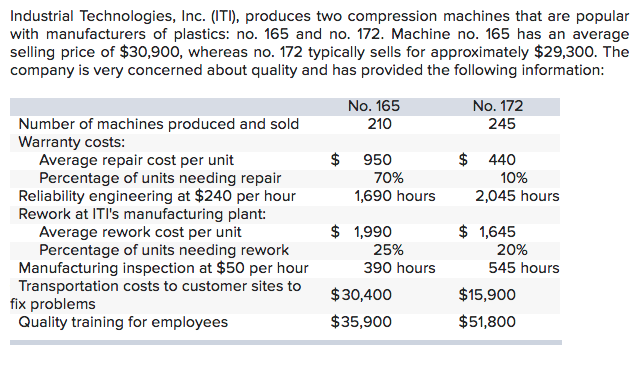

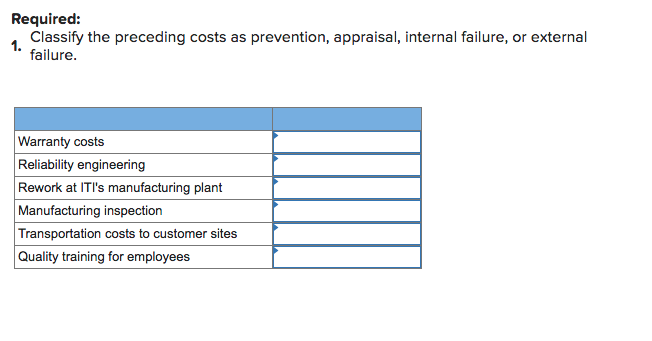

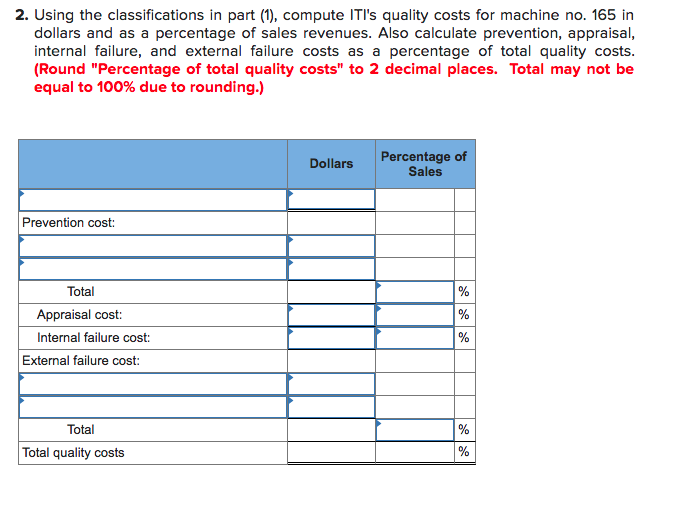

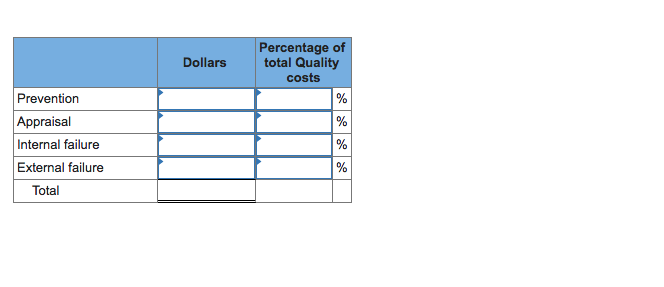

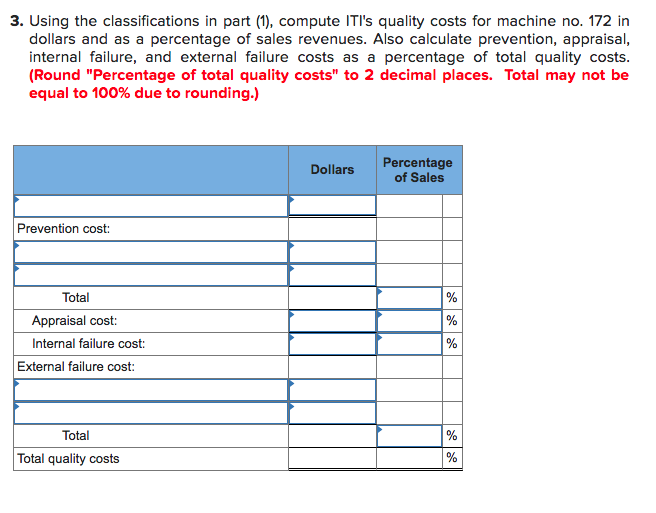

Industrial Technologies, Inc. (ITI), produces two compression machines that are popular with manufacturers of plastics: no. 165 and no. 172. Machine no. 165 has an average selling price of $30,900, whereas no. 172 typically sells for approximately $29,300. The company is very concerned about quality and has provided the following information No. 172 245 No. 165 Number of machines produced and sold Warranty costs Average repair cost per unit $ 950 $440 Percentage of units needing repair Reliability engineering at $240 per hour Rework at ITI's manufacturing plant: 70% 1,690 hours 10% 2,045 hours Average rework cost per unit $ 1,990 $1,645 Percentage of units needing rework Manufacturing inspection at $50 per hour Transportation costs to customer sites to 25% 390 hours 20% 545 hours $30,400 $35,900 $15,900 $51,800 fix problems Quality training for employees Required: 1. Classify the preceding costs as prevention, appraisal, internal failure, or external failure. Warranty costs Reliability engineering Rework at ITI's manufacturing plant Manufacturing inspection Transportation costs to customer sites Quality training for employees 2. Using the classifications in part (1), compute ITI's quality costs for machine no. 165 in dollars and as a percentage of sales revenues. Also calculate prevention, appraisal, internal failure, and external failure costs as a percentage of total quality costs. (Round "Percentage of total quality costs" to 2 decimal places. Total may not be equal to 100% due to rounding.) Percentage of Sales Dollars Prevention cost: Total Appraisal cost: Internal failure cost: External failure cost: Total Total quality costs Percentage of total Quality costs Dollars Prevention Appraisal Internal failure External failure Total 3. Using the classifications in part (1), compute ITI's quality costs for machine no. 172 in dollars and as a percentage of sales revenues. Also calculate prevention, appraisal, internal failure, and external failure costs as a percentage of total quality costs. (Round "Percentage of total quality costs" to 2 decimal places. Total may not be equal to 100% due to rounding.) Dollars Percentage of Sales Prevention cost: Total Appraisal cost: Internal failure cost: External failure cost: Total Total quality costs Percentage of total Quality costs Dollars Prevention Appraisal Internal failure External failure Total 4. Is the company "investing" its quality expenditures differently for the two machines. Yes O No