Question

Instructions: You are currently working on an improvement project to address the problem that customer demand for widget output is not being met. Your company

Instructions: You are currently working on an improvement project to address the problem that customer demand for widget output is not being met. Your company is growing quickly, customers love your widgets, and you are having trouble keeping up with demand. You will measure the extent of the problem, make improvements, measure again, and repeat improvements and measurements until customer demand is met. Fill out the yellow areas to complete the assignment.

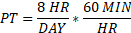

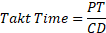

Your first task is to figure out Takt time. Takt time is expressed as production time divided by average

customer demand during that production time. You know that the customer wants 1600 widgets per day and the production facility has one 8-hour shift per day. You want to figure out the Takt time in minutes per unit so that you can more easily do other calculations to measure the extent of the problem and make improvements. I.e., how many minutes per unit would be allowed for the facility to be able to meet customer demand?

| TAKT TIME | |

| Customer demand in units per day CD (given): | CD = _____ UNITS/DAY |

| Production time in minutes per day:

| PT = _____ MIN/DAY |

| Takt time in minutes per unit:

| Takt Time = _____ MIN/UNIT |

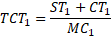

Next you will figure out the current widget output rate to see how it compares to Takt time. This rate is known as the throughput rate. You know that the production facility is currently putting out 300 acceptable units per day. You will use the Littles Law formula to figure out the throughput rate in units per minute. Then take the inverse of the throughput rate to get total cycle time per unit to compare to Takt time.

| ROUND 1 TOTAL CYCLE TIME PER UNIT | |

| Daily acceptable output in units per day DAO1 (given): | DAO1 = _____ UNITS/DAY |

| Throughput rate in units per minute (Littles Law):

| TR1 = _____ UNITS/MIN |

| Total cycle time in minutes per unit:

| TCT1 = _____MIN/UNIT |

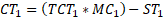

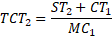

Your mission is to get the TCT to be lower than the Takt time. Right now it is higher. Your project team will make iterative improvements to reduce the TCT. The most obvious change that is feasible to make is to switch from online setup (ST) to offline setup as the first improvement to reduce the TCT. Offline setup is setting up Widget #2 for production without using up the production machine and while Widget #1 is still running on the machine. Switching to offline setup has reduced the online setup time (ST) by 89% from 0.9 minutes per unit (ST1) to 0.1 minutes per unit (ST2). One production machine (MC) is currently being used to make the widgets. Calculate the cycle time (CT1) per unit after setup, then calculate the new TCT2 based on offline setup.

| ROUND 2 TOTAL CYCLE TIME PER UNIT WITH OFFLINE SETUP | |

| Total cycle time in minutes per unit formula:

| ------- |

| Number of machines MC1 (given): | MC1 = _____ |

| Old setup time in minutes per unit ST1 (given): | ST1 = _____ MIN/UNIT |

| Cycle time in minutes per unit (rearrange TCT formula):

| CT1 = _____ MIN/UNIT |

| New setup time in minutes per unit ST2 (given): | ST2 = _____ MIN/UNIT |

| New total cycle time in minutes per unit:

| TCT2 = _____ MIN/UNIT |

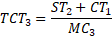

Your TCT2 is still higher than the Takt time. Your project team decides to invest in another production machine to further reduce the TCT. Calculate the new TCT3 based on 2 production machines and the recently improved setup time ST2.

| ROUND 3 TOTAL CYCLE TIME PER UNIT WITH 2 MACHINES | |

| New number of machines MC3 (given): | MC3 = _____ |

| New total cycle time in minutes per unit:

| TCT3 = _____ MIN/UNIT |

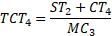

Your TCT3 is looking much better but could still use some improvement to meet customer demand. Your project team decides that better tooling will machine the widgets faster and reduce the cycle time (CT) per unit after setup. Switching to better tooling has reduced the CT to 0.53 minutes per unit (CT4). Calculate the new TCT4 based on the improved CT4, 2 production machines, and the recently improved setup time ST2.

| ROUND 4 TOTAL CYCLE TIME PER UNIT WITH BETTER TOOLING | |

| New cycle time per unit after setup CT4 (given): | CT4 = _____ MIN/UNIT |

| New total cycle time in minutes per unit:

| TCT4 = _____ MIN/UNIT |

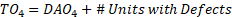

Your TCT4 is getting close to meeting customer demand. Your project team decides that defect reduction would be the best way to get the TCT under Takt time. You will do that by upgrading components on the production machines so there will be fewer machine failures that damage the widgets in process. Calculate the latest daily acceptable output DAO4 based on TCT4. Right now the facility is producing DAO4 acceptable units/day + 200 units with defects per day. Calculate the current total output (TO4) and current throughput yield (TY4) considering the defects.

| ROUND 4 THROUGHPUT YIELD | |

| Daily acceptable output in units per day:

| DAO4 = _____ UNITS/DAY |

| Total output:

| TO4 = _____ UNITS/DAY |

| Throughput yield without defect reduction:

| TY4 = _____% |

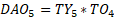

The defect reduction improvement results in a new throughput yield of 97% (TY5). Calculate the new daily acceptable output DAO5 based on TY5 and the existing total output TO4. Then calculate the TCT5 based on DAO5.

| ROUND 5 TOTAL CYCLE TIME PER UNIT WITH DEFECT REDUCTION | |

| New throughput yield TY5 (given): | TY5 = _____% |

| New daily acceptable output in units per day (rearrange TY formula):

| DAO5 = _____ UNITS/DAY |

| New total cycle time in minutes per unit:

| TCT5 = _____ MIN/UNIT |

Congratulations! Your TCT is less than your Takt time, which means that you can now meet the customer demand of 1600 units per day. Your initial calculations (Round 1) and four rounds of improvements (Rounds 2-5) including implementation of offline setup, adding another production machine, switching to better tooling, and reducing defects, have paid off.

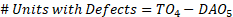

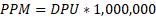

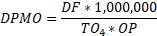

97% throughput yield is not bad, but how good is it in the grand scheme of things? Lets do some quality performance calculations to figure out where your organizations performance stands. Some of your units have more than one defect. As a result, there are 78 defects total in one day. There are 3 opportunities for a defect to occur in one unit, meaning the hole could be messed up, the length could be wrong, and/or the width could be wrong. Calculate the following quality metrics below.

| ROUND 5 QUALITY PERFORMANCE | |

| Number of defects DF (given): | DF = _____ |

| Number of opportunities per unit OP (given): | OP = _____ |

| Total output TO4: | TO4 = _____ |

| Number of units with defects:

| # Units with Defects = _____ |

| Average number of defects per unit (uses total output rather than # units with defects):

| DPU = _____ |

| Parts (defects) per million units PPM:

| PPM = _____ |

| Defects per million opportunities DPMO:

| DPMO = _____ |

| Sigma level (use the table below to find the right sigma level based on your calculated DPMO): | Sigma Level = _____ |

| DPMO | SIGMA LEVEL |

| 308,500 | 2.0 |

| 158,700 | 2.5 |

| 66,800 | 3.0 |

| 22,700 | 3.5 |

| 6,200 | 4.0 |

| 1,300 | 4.5 |

| 230 | 5.0 |

| 30 | 5.5 |

| 3.4 | 6.0 |

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started