Answered step by step

Verified Expert Solution

Question

1 Approved Answer

Lawn King produces a couple models of push lawn mowers. A total of 6 0 workers are currently employed to work on the assembly line.

Lawn King produces a couple models of push lawn mowers. A total of workers are currently employed to work on the assembly line. Hiring cost is $ for each new employee, while the cost of laying off an employee is $ The production strategy in current use is a oneshiftperday level strategy at average demand. Differences between demand and production are balanced by inventory

and backorders. If a backorder occurs, the order is filled from the next available production run and safety stock is consumed if needed and replenished later. Lawn King utilizes a $unit carrying cost per month for inventory, and backorders have a cost of $unit per month. Production is estimated at mowers per worker per shift, and the assembly line operates working days shifts per month. Lawn

King keeps mowers as safety stock, which will be the beginning inventory for September. The regular time cost of production is $ per lawn mower.

Hint: production # of workers# of mowers each worker produces per shift# of shifts per month

Each May an aggregate production plan is prepared for the upcoming fiscal year that starts in September. The aggregate plan is used for personnel planning, inventory planning, and budget preparation.

Develop an aggregate plan for fiscal using the forecasts below

a using their level strategy

b using a chase strategy by varying the number of workers

Sept

Oct

Nov

Dec

Jan

Feb

March

Apr

May

Jun

Jul

Aug

Calculate the economic order quantitiy. Because of the high setup cost of $order for producing push lawnmowers, production is ordered in specified quantities instead of lotforlot. Calculate the economic order quantity for push mowers assume independent of model; holding cost are given above This quantity will be used as the lot size for the MRPHint convert holding cost given above to annual in this calculation.

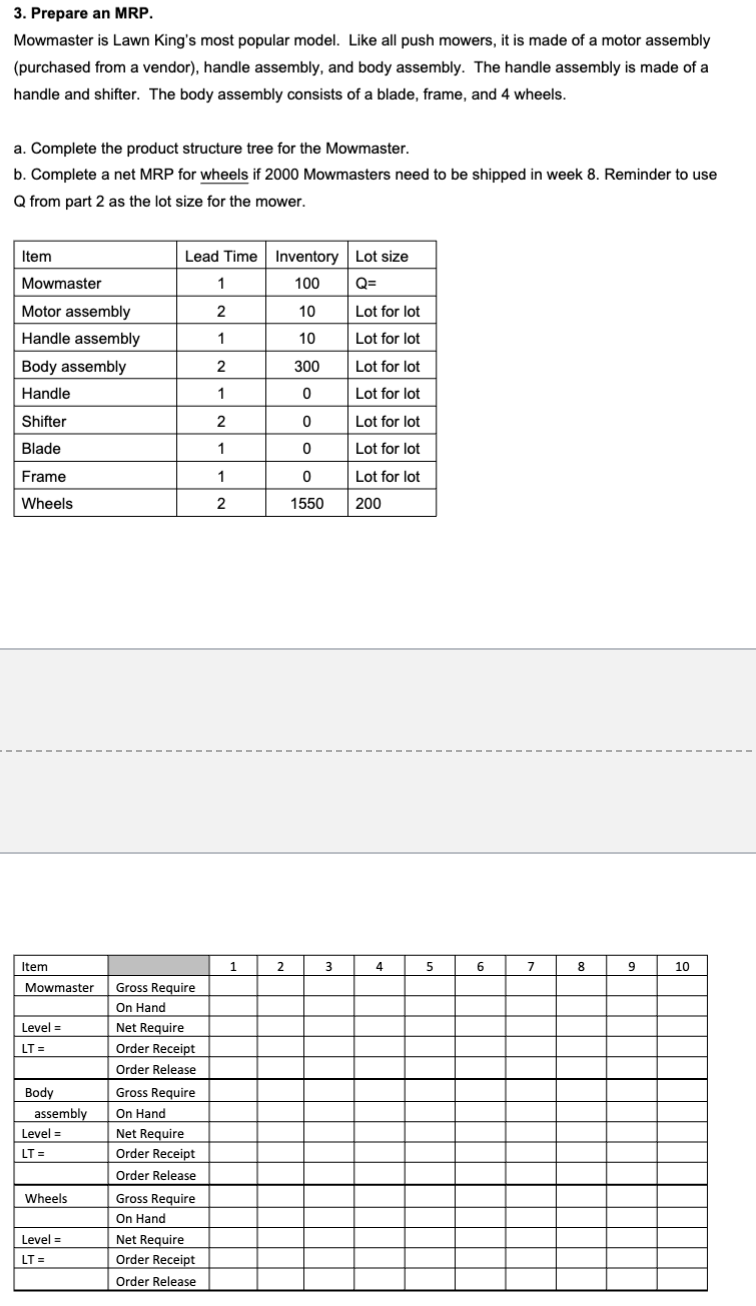

Prepare an MRP

Mowmaster is Lawn King's most popular model. Like all push mowers, it is made of a motor assembly purchased from a vendor handle assembly, and body assembly. The handle assembly is made of a handle and shifter. The body assembly consists of a blade, frame, and wheels.

a Complete the product structure tree for the Mowmaster.

b Complete a net MRP for wheels if Mowmasters need to be shipped in week Reminder to use from part as the lot size for the mower.

tableItemLead Time,Inventory,Lot sizeMowmasterQMotor assembly,Lot for lotHandle assembly,Lot for lotBody assembly,Lot for lotHandleLot for lotShifterLot for lotBladeLot for lotFrameLot for lotWheels

tableItemMowmasterGross Require,,,,,,,,,,On Hand,,,,,,,,,,Level Net Require,,,,,,,,,,LT Order Receipt,,,,,,,,,,Order Release,,,,,,,,,,BodyGross Require,,,,,,,,,,assemblyOn Hand,,,,,,,,,,Level Net Require,,,,,,,,,,LT Order Receipt,,,,,,,,,,Order Release,,,,,,,,,,WheelsGross Require,,,,,,,,,,On Hand,,,,,,,,,,Level Net Require,,,,,,,,,,LT Order Receipt,,,,,,,,,,Order Release,,,,,,,,,,

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started