Answered step by step

Verified Expert Solution

Question

1 Approved Answer

MakeUp Homework Part 1: Diameter measurements of a part produced in a factory with standard production parameter settings is listed in the excel file under

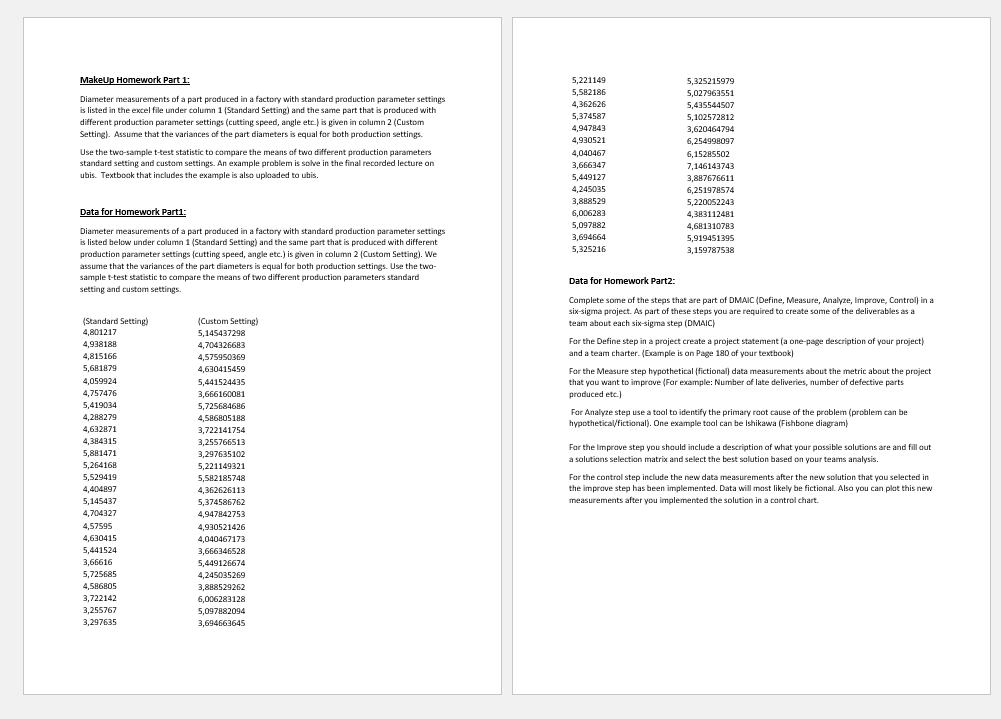

MakeUp Homework Part 1: Diameter measurements of a part produced in a factory with standard production parameter settings is listed in the excel file under column 1 (Standard Setting) and the same part that is produced with different production parameter settings (cutting speed, angle etc.) is given in column 2 (Custom Setting). Assume that the variances of the part diameters is equal for both production settings. Use the two-sample t-test statistic to compare the means of two different production parameters standard setting and custom settings. An example problem is solve in the final recorded lecture on ubis. Textboak that includes the example is also uplasded to ubis. Data for Homework Part1: Diameter measurements of a part produced in a factory with standard production parameter settings is listed below under column 1 (Standard Setting) and the same part that is produced with different production parameter settings (cutting speed, angle etc.) is given in column 2 (Custom Setting). We assume that the variances of the part diameters is equal for both production settings. Use the twosample t-test statistic to compare the means of two different production parameters standard setting and custam settings. Data for Homework Part2: Complete some of the steps that are part of DMAIC (Define, Measure, Analyze, Improve, Control) in a six-sigma project. As part of these steps you are required to create some of the beliverables as a team about each six-sigma step (DMAIC) For the Define step in a project create a project statement (a one-page description of your project) and a team charter. (Example is an Page 180 of your textbook) For the Measure step hypothetical (fictional) data measurements about the metric about the project that you want to imprave /For example: Number of late deliveries, number of defective parts produced etc.) For Analyze step use a tool to identify the primary root cause of the problem (problem can be hypothetical/fictional). One example tool can be Ishikawa (Fishbone diagram) For the Improve step you should include a bescription of what your possible solutions are and fill out a solutions selection matrix and select the best solution based on your teams analysis. For the contral step include the new data measurements after the new solution that you selected in the imprave step has been implemented. Data will most likely be fictional. Alsa you can plat this new measurements after you implemented the solution in a control chart

MakeUp Homework Part 1: Diameter measurements of a part produced in a factory with standard production parameter settings is listed in the excel file under column 1 (Standard Setting) and the same part that is produced with different production parameter settings (cutting speed, angle etc.) is given in column 2 (Custom Setting). Assume that the variances of the part diameters is equal for both production settings. Use the two-sample t-test statistic to compare the means of two different production parameters standard setting and custom settings. An example problem is solve in the final recorded lecture on ubis. Textboak that includes the example is also uplasded to ubis. Data for Homework Part1: Diameter measurements of a part produced in a factory with standard production parameter settings is listed below under column 1 (Standard Setting) and the same part that is produced with different production parameter settings (cutting speed, angle etc.) is given in column 2 (Custom Setting). We assume that the variances of the part diameters is equal for both production settings. Use the twosample t-test statistic to compare the means of two different production parameters standard setting and custam settings. Data for Homework Part2: Complete some of the steps that are part of DMAIC (Define, Measure, Analyze, Improve, Control) in a six-sigma project. As part of these steps you are required to create some of the beliverables as a team about each six-sigma step (DMAIC) For the Define step in a project create a project statement (a one-page description of your project) and a team charter. (Example is an Page 180 of your textbook) For the Measure step hypothetical (fictional) data measurements about the metric about the project that you want to imprave /For example: Number of late deliveries, number of defective parts produced etc.) For Analyze step use a tool to identify the primary root cause of the problem (problem can be hypothetical/fictional). One example tool can be Ishikawa (Fishbone diagram) For the Improve step you should include a bescription of what your possible solutions are and fill out a solutions selection matrix and select the best solution based on your teams analysis. For the contral step include the new data measurements after the new solution that you selected in the imprave step has been implemented. Data will most likely be fictional. Alsa you can plat this new measurements after you implemented the solution in a control chart Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started