Answered step by step

Verified Expert Solution

Question

1 Approved Answer

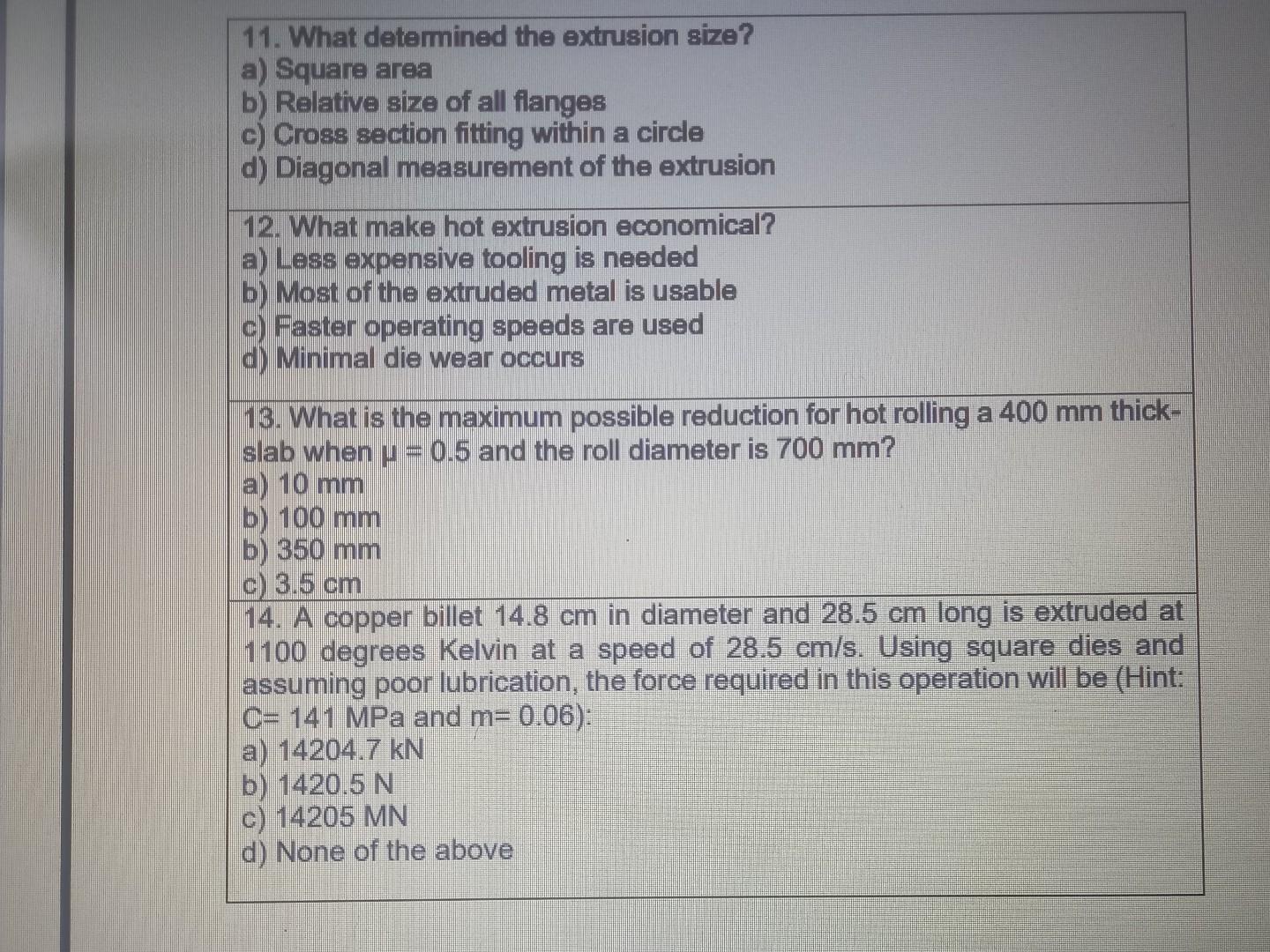

Manufacturing questions 11. What determined the extrusion size? a) Square area b) Relative size of all flanges c) Cross section fitting within a circle d)

Manufacturing questions

11. What determined the extrusion size? a) Square area b) Relative size of all flanges c) Cross section fitting within a circle d) Diagonal measurement of the extrusion 12. What make hot extrusion economical? a) Less expensive tooling is needed b) Most of the extruded metal is usable c) Faster operating speeds are used d) Minimal die wear occurs 13. What is the maximum possible reduction for hot rolling a 400mm thickslab when =0.5 and the roll diameter is 700mm ? a) 10mm b) 100mm b) 350mm c) 3.5cm 14. A copper billet 14.8cm in diameter and 28.5cm long is extruded at 1100 degrees Kelvin at a speed of 28.5cm/s. Using square dies and assuming poor lubrication, the force required in this operation will be (Hint: C=141MPa and m=0.06 ): a) 14204.7kN b) 1420.5N c) 14205MN d) None of the aboveStep by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started