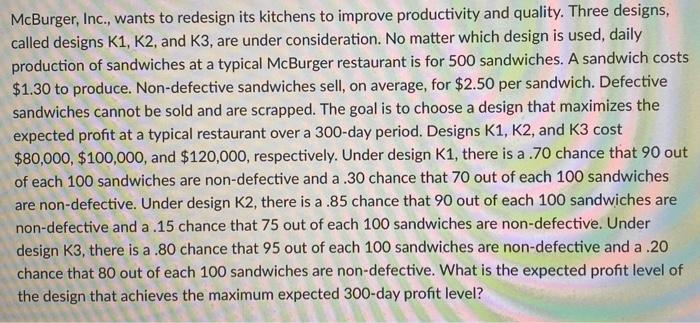

McBurger, Inc., wants to redesign its kitchens to improve productivity and quality. Three designs, called designs K1,K2, and K3, are under consideration. No matter which design is used, daily production of sandwiches at a typical McBurger restaurant is for 500 sandwiches. A sandwich costs $1.30 to produce. Non-defective sandwiches sell, on average, for $2.50 per sandwich. Defective sandwiches cannot be sold and are scrapped. The goal is to choose a design that maximizes the expected profit at a typical restaurant over a 300 -day period. Designs K1,K2, and K3 cost $80,000,$100,000, and $120,000, respectively. Under design K1, there is a .70 chance that 90 out of each 100 sandwiches are non-defective and a .30 chance that 70 out of each 100 sandwiches are non-defective. Under design K2, there is a .85 chance that 90 out of each 100 sandwiches are non-defective and a .15 chance that 75 out of each 100 sandwiches are non-defective. Under design K3, there is a .80 chance that 95 out of each 100 sandwiches are non-defective and a .20 chance that 80 out of each 100 sandwiches are non-defective. What is the expected profit level of the design that achieves the maximum expected 300 -day profit level? McBurger, Inc., wants to redesign its kitchens to improve productivity and quality. Three designs, called designs K1,K2, and K3, are under consideration. No matter which design is used, daily production of sandwiches at a typical McBurger restaurant is for 500 sandwiches. A sandwich costs $1.30 to produce. Non-defective sandwiches sell, on average, for $2.50 per sandwich. Defective sandwiches cannot be sold and are scrapped. The goal is to choose a design that maximizes the expected profit at a typical restaurant over a 300 -day period. Designs K1,K2, and K3 cost $80,000,$100,000, and $120,000, respectively. Under design K1, there is a .70 chance that 90 out of each 100 sandwiches are non-defective and a .30 chance that 70 out of each 100 sandwiches are non-defective. Under design K2, there is a .85 chance that 90 out of each 100 sandwiches are non-defective and a .15 chance that 75 out of each 100 sandwiches are non-defective. Under design K3, there is a .80 chance that 95 out of each 100 sandwiches are non-defective and a .20 chance that 80 out of each 100 sandwiches are non-defective. What is the expected profit level of the design that achieves the maximum expected 300 -day profit level