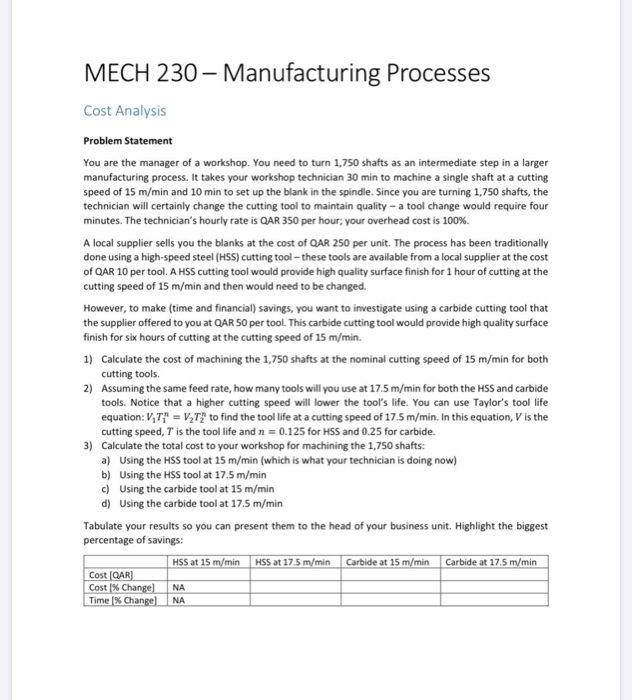

MECH 230 - Manufacturing Processes Cost Analysis Problem Statement You are the manager of a workshop. You need to turn 1,750 shafts as an intermediate step in a larger manufacturing process. It takes your workshop technician 30 min to machine a single shaft at a cutting speed of 15 m/min and 10 min to set up the blank in the spindle. Since you are turning 1,750 shafts, the technician will certainly change the cutting tool to maintain quality - a tool change would require four minutes. The technician's hourly rate is QAR 350 per hour; your overhead cost is 100% A local supplier sells you the blanks at the cost of QAR 250 per unit. The process has been traditionally done using a high-speed steel (HSS) cutting tool-these tools are available from a local supplier at the cost of QAR 10 per tool. A HSS cutting tool would provide high quality surface finish for 1 hour of cutting at the cutting speed of 15 m/min and then would need to be changed. However, to make (time and financial) savings, you want to investigate using a carbide cutting tool that the supplier offered to you at QAR 50 per tool. This carbide cutting tool would provide high quality surface finish for six hours of cutting at the cutting speed of 15 m/min. 1) Calculate the cost of machining the 1,750 shafts at the nominal cutting speed of 15 m/min for both cutting tools. 2) Assuming the same feed rate, how many tools will you use at 17.5 m/min for both the HSS and carbide tools. Notice that a higher cutting speed will lower the tool's life. You can use Taylor's tool life equation: V T = V27" to find the tool life at a cutting speed of 17.5 m/min. In this equation, V is the cutting speed, T is the tool life and n = 0.125 for HSS and 0.25 for carbide. 3) Calculate the total cost to your workshop for machining the 1,750 shafts: a) Using the HSS tool at 15 m/min (which is what your technician is doing now) b) Using the HSS tool at 17.5 m/min c) Using the carbide tool at 15 m/min d) Using the carbide tool at 17.5 m/min Tabulate your results so you can present them to the head of your business unit. Highlight the biggest percentage of savings: HSS at 15 m/min HSS at 17.5 m/min Carbide at 15 m/min Carbide at 17.5 m/min Cost (QAR) Cost (% Change) Time [% Change) NA NA