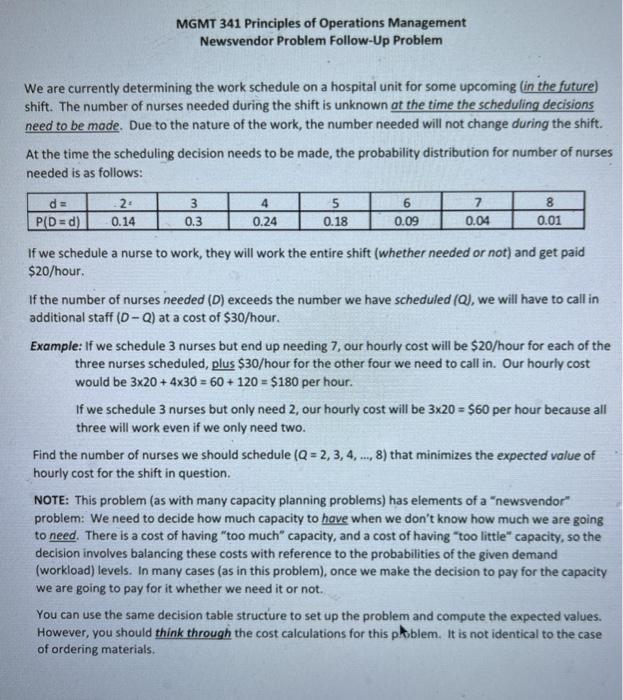

MGMT 341 Principles of Operations Management Newsvendor Problem Follow-Up Problem We are currently determining the work schedule on a hospital unit for some upcoming in the future) shift. The number of nurses needed during the shift is unknown at the time the scheduling decisions need to be made. Due to the nature of the work, the number needed will not change during the shift. At the time the scheduling decision needs to be made, the probability distribution for number of nurses needed is as follows: 4 5 2 0.14 3 0.3 6 0.09 7 0.04 8 0.01 PD = d) 0.24 0.18 If we schedule a nurse to work, they will work the entire shift (whether needed or not) and get paid $20/hour. If the number of nurses needed (D) exceeds the number we have scheduled (Q), we will have to call in additional staff (D-Q) at a cost of $30/hour. Example: If we schedule 3 nurses but end up needing 7, our hourly cost will be $20/hour for each of the three nurses scheduled, plus $30/hour for the other four we need to call in. Our hourly cost would be 3x20 + 4x30 = 60 + 120 = $180 per hour. If we schedule 3 nurses but only need 2, our hourly cost will be 3x20 = $60 per hour because all three will work even if we only need two. Find the number of nurses we should schedule (Q = 2, 3, 4, ..., 8) that minimizes the expected value of hourly cost for the shift in question. NOTE: This problem (as with many capacity planning problems) has elements of a "newsvendor" problem: We need to decide how much capacity to have when we don't know how much we are going to need. There is a cost of having "too much" capacity, and a cost of having too little" capacity, so the decision involves balancing these costs with reference to the probabilities of the given demand (workload) levels. In many cases (as in this problem), once we make the decision to pay for the capacity we are going to pay for it whether we need it or not. You can use the same decision table structure to set up the problem and compute the expected values. However, you should think through the cost calculations for this poblem. It is not identical to the case of ordering materials. MGMT 341 Principles of Operations Management Newsvendor Problem Follow-Up Problem We are currently determining the work schedule on a hospital unit for some upcoming in the future) shift. The number of nurses needed during the shift is unknown at the time the scheduling decisions need to be made. Due to the nature of the work, the number needed will not change during the shift. At the time the scheduling decision needs to be made, the probability distribution for number of nurses needed is as follows: 4 5 2 0.14 3 0.3 6 0.09 7 0.04 8 0.01 PD = d) 0.24 0.18 If we schedule a nurse to work, they will work the entire shift (whether needed or not) and get paid $20/hour. If the number of nurses needed (D) exceeds the number we have scheduled (Q), we will have to call in additional staff (D-Q) at a cost of $30/hour. Example: If we schedule 3 nurses but end up needing 7, our hourly cost will be $20/hour for each of the three nurses scheduled, plus $30/hour for the other four we need to call in. Our hourly cost would be 3x20 + 4x30 = 60 + 120 = $180 per hour. If we schedule 3 nurses but only need 2, our hourly cost will be 3x20 = $60 per hour because all three will work even if we only need two. Find the number of nurses we should schedule (Q = 2, 3, 4, ..., 8) that minimizes the expected value of hourly cost for the shift in question. NOTE: This problem (as with many capacity planning problems) has elements of a "newsvendor" problem: We need to decide how much capacity to have when we don't know how much we are going to need. There is a cost of having "too much" capacity, and a cost of having too little" capacity, so the decision involves balancing these costs with reference to the probabilities of the given demand (workload) levels. In many cases (as in this problem), once we make the decision to pay for the capacity we are going to pay for it whether we need it or not. You can use the same decision table structure to set up the problem and compute the expected values. However, you should think through the cost calculations for this poblem. It is not identical to the case of ordering materials