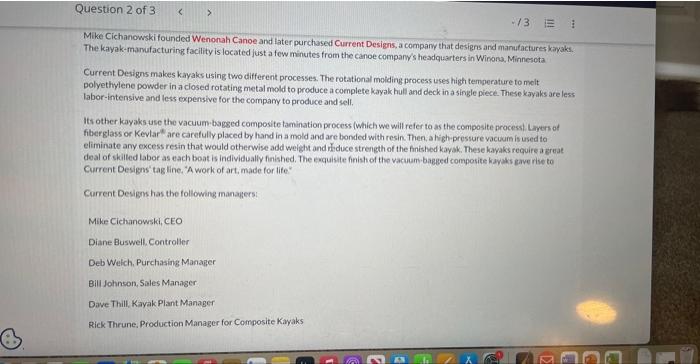

Mike Cichanowski founded Wenonah Canoe and later purchasedi Current Designs, a company that designs and manufactures kayaks. The kayak-manufacturing facility is located just a few minutes from the canoe companys headquarters in Winona, Minnesota Current Designs makes kayaks using two different processes. The rotational moiding process uses high temperature to melt polyethylene powder in a closed rotating metal mold to produce a complete kayak hull and deck in asingle piece. These kayaks are less labor-intensive and less copensive for the compary to produce and sell. Its other kayaks use the vacuum bagged composite tamination process (which we will refer to as the composite processi). Liyern of fiberglass or Kevlar: are carefully placed by hand in a mold and are bonded with resin. Then, a high-pressure vacuum is used to eliminate any excess resin that would otherwise add weight and hiduce strength of the finished kayak. These kayaks require a great deal of skilled labor as each boat is individually finished. The exquisite finish of the vacuumbagged composite kayaks gave rise to Current Designs' tag line, "A work of art, made for life" Current Designs has the following manayers: Mike Cichanowsici, CEO Diane Buswell. Controlier Deb Welch, Purchasing Manager Bill Johnson, Sales Manager Dave Thill, Kayak Plant Manager Rick Thrune, Production Manager for Composite Kayaks Mike Cichanowski founded Wenonah Canoe and later purchasedi Current Designs, a company that designs and manufactures kayaks. The kayak-manufacturing facility is located just a few minutes from the canoe companys headquarters in Winona, Minnesota Current Designs makes kayaks using two different processes. The rotational moiding process uses high temperature to melt polyethylene powder in a closed rotating metal mold to produce a complete kayak hull and deck in asingle piece. These kayaks are less labor-intensive and less copensive for the compary to produce and sell. Its other kayaks use the vacuum bagged composite tamination process (which we will refer to as the composite processi). Liyern of fiberglass or Kevlar: are carefully placed by hand in a mold and are bonded with resin. Then, a high-pressure vacuum is used to eliminate any excess resin that would otherwise add weight and hiduce strength of the finished kayak. These kayaks require a great deal of skilled labor as each boat is individually finished. The exquisite finish of the vacuumbagged composite kayaks gave rise to Current Designs' tag line, "A work of art, made for life" Current Designs has the following manayers: Mike Cichanowsici, CEO Diane Buswell. Controlier Deb Welch, Purchasing Manager Bill Johnson, Sales Manager Dave Thill, Kayak Plant Manager Rick Thrune, Production Manager for Composite Kayaks