need help with 1-4 please

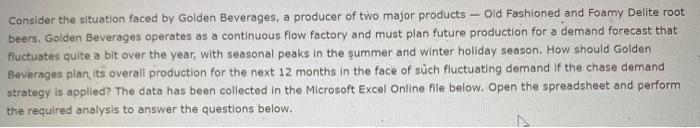

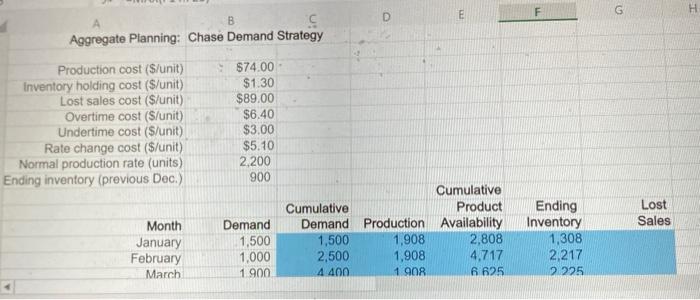

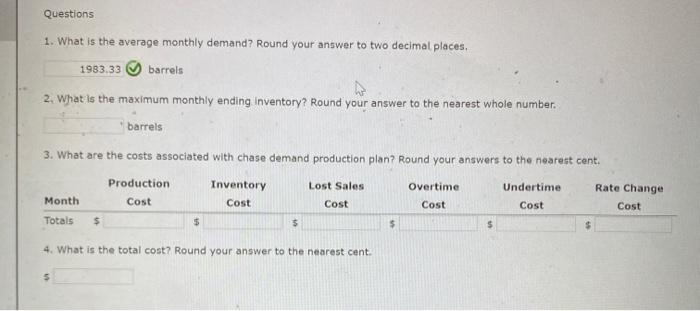

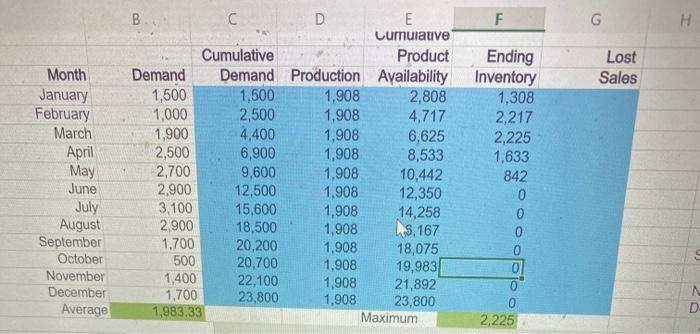

Consider the situation faced by Golden Beverages, a producer of two major products - Old Fashioned and Foamy Delite root beers. Golden Beverages operates as a continuous flow factory and must plan future production for a demand forecast that fluctuates quite a bit over the year, with seasonal peaks in the summer and winter holiday season. How should Golden Beverages plan its overall production for the next 12 months in the face of such fluctuating demand if the chase demand strategy is applied? The data has been collected in the Microsoft Excel Online file below. Open the spreadsheet and perform the required analysis to answer the questions below. D E F G Aggregate Planning: Chase Demand Strategy Production cost ($/unit) Inventory holding cost ($/unit) Lost sales cost ($/unit) Overtime cost (S/unit) Undertime cost (S/unit) Rate change cost ($/unit) Normal production rate (units) Ending inventory (previous Dec.) $74.00 $1.30 $89.00 $6.40 $3.00 $5.10 2,200 900 Lost Sales Month January February March Demand 1,500 1,000 1900 Cumulative Cumulative Product Demand Production Availability 1,500 1,908 2,808 2,500 1,908 4,717 4.400 1.908 625 Ending Inventory 1,308 2,217 2.225 Questions 1. What is the average monthly demand? Round your answer to two decimal places. 1983.33 barrels 2. What is the maximum monthly ending Inventory? Round your answer to the nearest whole number. barrels 3. What are the costs associated with chase demand production plan? Round your answers to the nearest cent. Production Inventory Lost Sales Overtime Undertime Rate Change Month Cost Cost Cost Cost Cost Cost Totals $ 5 5 $ 4. What is the total cost? Round your answer to the nearest cent. B F G H Lost Sales Month January February March April May June July August September October November December Average B C D E Cumuiauve Cumulative Product Demand Demand Production Availability 1,500 1,500 1,908 2,808 1,000 2,500 1,908 4,717 1,900 4,400 1,908 6,625 2,500 6,900 1,908 8,533 2,700 9,600 1,908 10,442 2,900 12,500 1,908 12,350 3,100 15,600 1,908 14,258 2,900 18,500 1,908 1S. 167 1,700 20,200 1,908 18,075 500 20,700 1,908 19,983 1,400 22,100 1,908 21,892 1,700 23,800 1,908 23,800 1,983.33 Maximum Ending Inventory 1,308 2,217 2,225 1,633 842 0 0 0 0 0 0 2,225 Consider the situation faced by Golden Beverages, a producer of two major products - Old Fashioned and Foamy Delite root beers. Golden Beverages operates as a continuous flow factory and must plan future production for a demand forecast that fluctuates quite a bit over the year, with seasonal peaks in the summer and winter holiday season. How should Golden Beverages plan its overall production for the next 12 months in the face of such fluctuating demand if the chase demand strategy is applied? The data has been collected in the Microsoft Excel Online file below. Open the spreadsheet and perform the required analysis to answer the questions below. D E F G Aggregate Planning: Chase Demand Strategy Production cost ($/unit) Inventory holding cost ($/unit) Lost sales cost ($/unit) Overtime cost (S/unit) Undertime cost (S/unit) Rate change cost ($/unit) Normal production rate (units) Ending inventory (previous Dec.) $74.00 $1.30 $89.00 $6.40 $3.00 $5.10 2,200 900 Lost Sales Month January February March Demand 1,500 1,000 1900 Cumulative Cumulative Product Demand Production Availability 1,500 1,908 2,808 2,500 1,908 4,717 4.400 1.908 625 Ending Inventory 1,308 2,217 2.225 Questions 1. What is the average monthly demand? Round your answer to two decimal places. 1983.33 barrels 2. What is the maximum monthly ending Inventory? Round your answer to the nearest whole number. barrels 3. What are the costs associated with chase demand production plan? Round your answers to the nearest cent. Production Inventory Lost Sales Overtime Undertime Rate Change Month Cost Cost Cost Cost Cost Cost Totals $ 5 5 $ 4. What is the total cost? Round your answer to the nearest cent. B F G H Lost Sales Month January February March April May June July August September October November December Average B C D E Cumuiauve Cumulative Product Demand Demand Production Availability 1,500 1,500 1,908 2,808 1,000 2,500 1,908 4,717 1,900 4,400 1,908 6,625 2,500 6,900 1,908 8,533 2,700 9,600 1,908 10,442 2,900 12,500 1,908 12,350 3,100 15,600 1,908 14,258 2,900 18,500 1,908 1S. 167 1,700 20,200 1,908 18,075 500 20,700 1,908 19,983 1,400 22,100 1,908 21,892 1,700 23,800 1,908 23,800 1,983.33 Maximum Ending Inventory 1,308 2,217 2,225 1,633 842 0 0 0 0 0 0 2,225