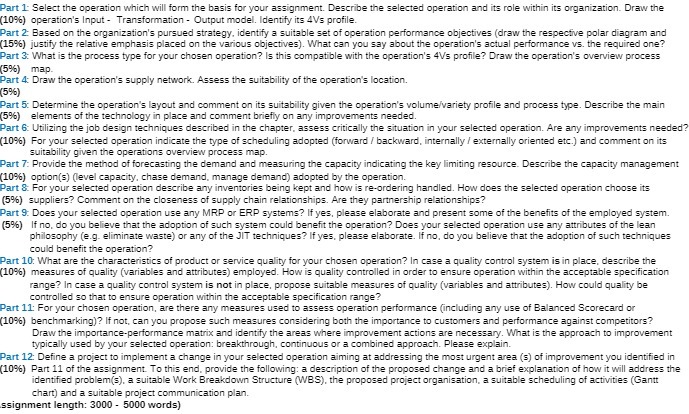

Part 1: Select the operation which will form the basis for your assignment. Describe the selected operation and its role within its organization. Draw the (10%) operation's Input - Transformation - Output model. Identify its 4V's profile. Part 2: Based on the organization's pursued strategy, identify a suitable set of operation performance objectives (draw the respective polar diagram and (15%) justify the relative emphasis placed on the various objectives). What can you say about the operation's actual performance vs. the required one? Part 3: What is the process type for your chosen operation? Is this compatible with the operation's 4Vs profile? Draw the operation's overview process 5%) map. Part 4: Draw the operation's supply network. Assess the suitability of the operation's location. (5%) Part 5: Determine the operation's layout and comment on its suitability given the operation's volume variety profile and process type. Describe the main (596) elements of the technology in place and comment briefly on any improvements needed. Part 6: Utilizing the job design techniques described in the chapter, assess critically the situation in your selected operation. Are any improvements needed? [109%) For your selected operation indicate the type of scheduling adopted (forward / backward, internally / externally oriented etc.) and comment on its suitability given the operations overview process map. Part 7: Provide the method of forecasting the demand and measuring the capacity indicating the key limiting resource. Describe the capacity management (10%) option(s) (level capacity, chase demand, manage demand) adopted by the operation. Part & For your selected operation describe any inventories being kept and how is re-ordering handled. How does the selected operation choose its (59%) suppliers? Comment on the closeness of supply chain relationships. Are they partnership relationships? Part 9: Does your selected operation use any MRP or ERP systems? If yes, please elaborate and present some of the benefits of the employed system. (5%) If no, do you believe that the adoption of such system could benefit the operation? Does your selected operation use any attributes of the lean philosophy (e.g- eliminate waste) or any of the JIT techniques? If yes, please elaborate. If no, do you believe that the adoption of such techniques could benefit the operation? Part 10: What are the characteristics of product or service quality for your chosen operation? In case a quality control system is in place, describe the (10%) measures of quality (variables and attributes) employed. How is quality controlled in order to ensure operation within the acceptable specification range? In case a quality control system is not in place, propose suitable measures of quality (variables and attributes). How could quality be controlled so that to ensure operation within the acceptable specification range? Part 11: For your chosen operation, are there any measures used to assess operation performance (including any use of Balanced Scorecard or (10%) benchmarking)? If not, can you propose such measures considering both the importance to customers and performance against competitors? Draw the importance-performance matrix and identify the areas where improvement actions are necessary. What is the approach to improvement typically used by your selected operation: breakthrough, continuous or a combined approach. Please explain. Part 12: Define a project to implement a change in your selected operation aiming at addressing the most urgent area (s) of improvement you identified in 109%) Part 11 of the assignment To this end, provide the following: a description of the proposed change and a brief explanation of how it will address the identified problem(s), a suitable Work Breakdown Structure (WBS), the proposed project organisation, a suitable scheduling of activities (Gantt chart) and a suitable project communication plan. ssignment length: 3000 - 5000 words)