Answered step by step

Verified Expert Solution

Question

1 Approved Answer

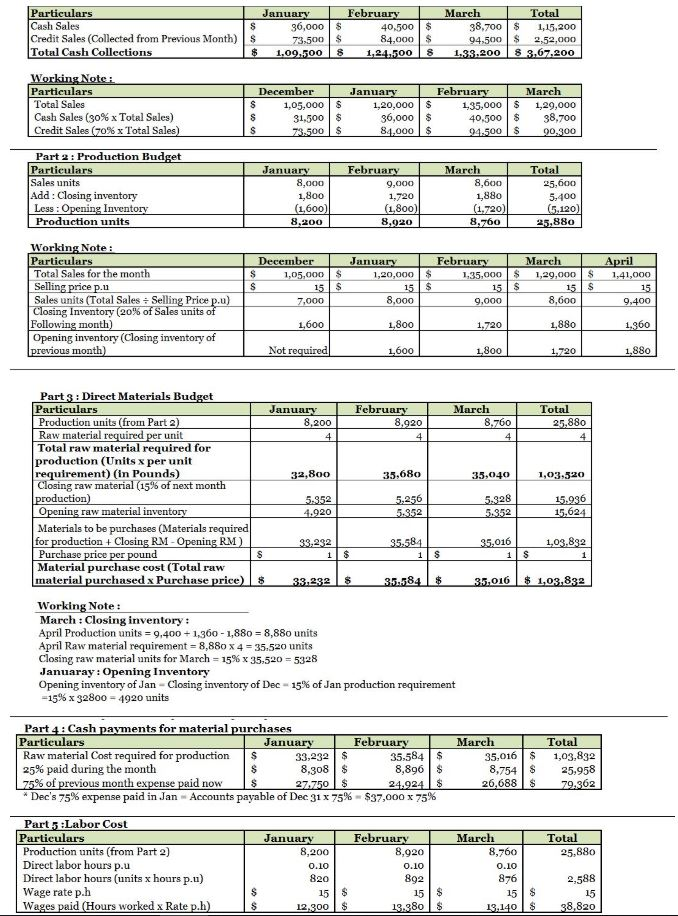

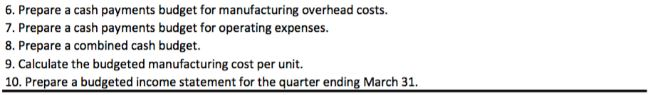

Parts 1-5 have all ready been done. Need help solving the remaing 6,7,8,9,10 Wasatch Manufacturing is preparing its master budget for the first quarter of

Parts 1-5 have all ready been done. Need help solving the remaing 6,7,8,9,10

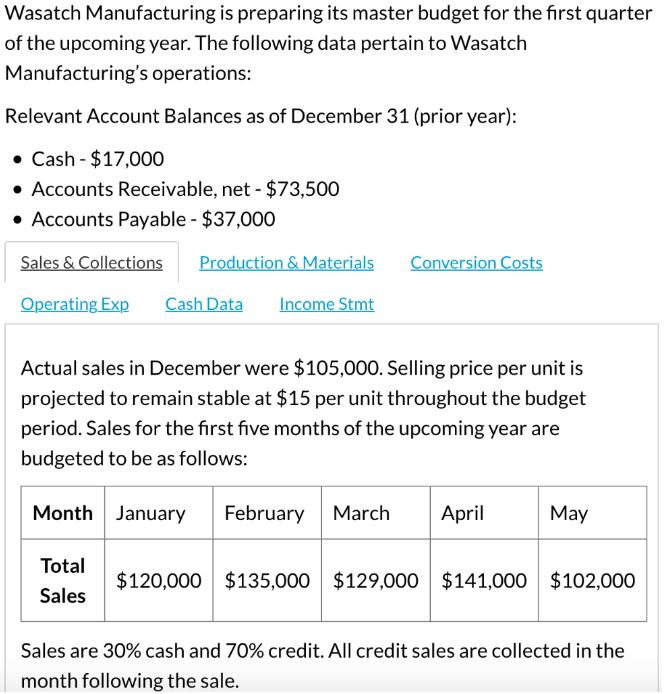

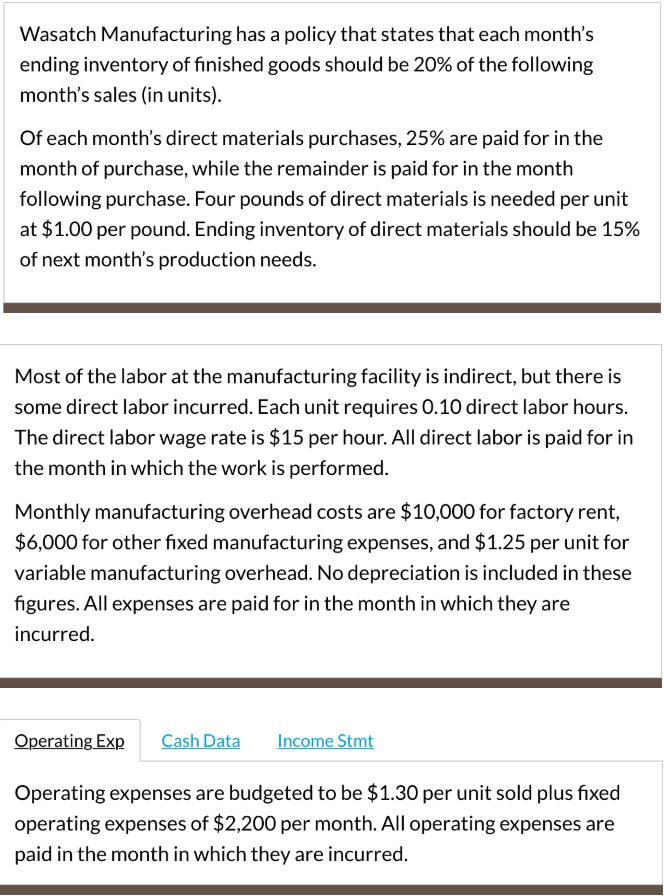

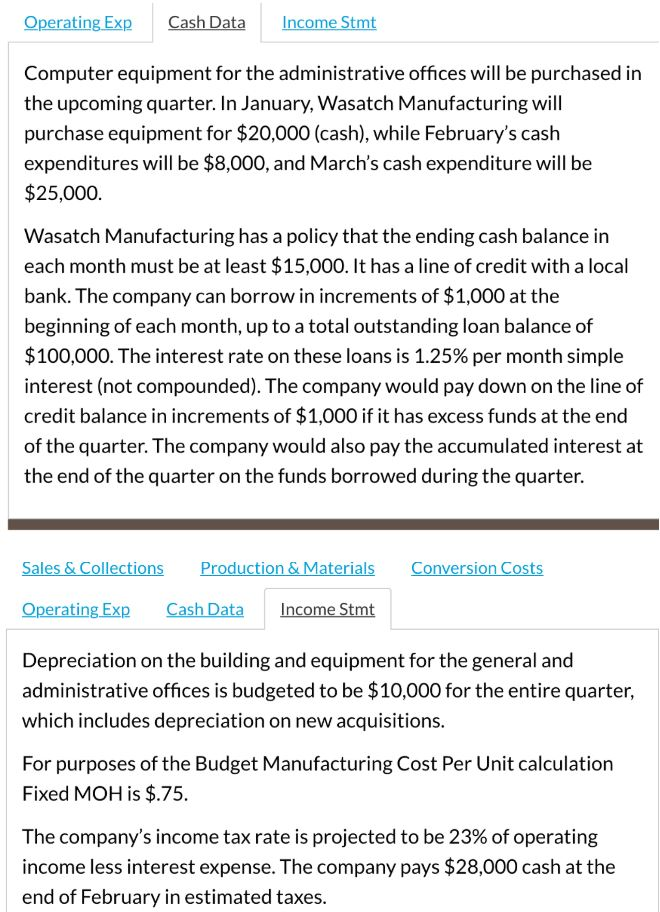

Wasatch Manufacturing is preparing its master budget for the first quarter of the upcoming year. The following data pertain to Wasatch Manufacturing's operations: Relevant Account Balances as of December 31 (prior year): Cash - $17,000 Accounts Receivable, net - $73,500 Accounts Payable - $37,000 Sales & Collections Production & Materials Conversion Costs Operating Exp Cash Data Income Stmt Actual sales in December were $105,000. Selling price per unit is projected to remain stable at $15 per unit throughout the budget period. Sales for the first five months of the upcoming year are budgeted to be as follows: Month January February March April May Total Sales $120,000 $135,000 $129,000 $141,000 $102,000 Sales are 30% cash and 70% credit. All credit sales are collected in the month following the sale. Wasatch Manufacturing has a policy that states that each month's ending inventory of finished goods should be 20% of the following month's sales (in units). Of each month's direct materials purchases, 25% are paid for in the month of purchase, while the remainder is paid for in the month following purchase. Four pounds of direct materials is needed per unit at $1.00 per pound. Ending inventory of direct materials should be 15% of next month's production needs. Most of the labor at the manufacturing facility is indirect, but there is some direct labor incurred. Each unit requires 0.10 direct labor hours. The direct labor wage rate is $15 per hour. All direct labor is paid for in the month in which the work is performed. Monthly manufacturing overhead costs are $10,000 for factory rent, $6,000 for other fixed manufacturing expenses, and $1.25 per unit for variable manufacturing overhead. No depreciation is included in these figures. All expenses are paid for in the month in which they are incurred. Operating Exp Cash Data Income Stmt Operating expenses are budgeted to be $1.30 per unit sold plus fixed operating expenses of $2,200 per month. All operating expenses are paid in the month in which they are incurred. Operating Exp Cash Data Income Stmt Computer equipment for the administrative offices will be purchased in the upcoming quarter. In January, Wasatch Manufacturing will purchase equipment for $20,000 (cash), while February's cash expenditures will be $8,000, and March's cash expenditure will be $25,000. Wasatch Manufacturing has a policy that the ending cash balance in each month must be at least $15,000. It has a line of credit with a local bank. The company can borrow in increments of $1,000 at the beginning of each month, up to a total outstanding loan balance of $100,000. The interest rate on these loans is 1.25% per month simple interest (not compounded). The company would pay down on the line of credit balance in increments of $1,000 if it has excess funds at the end of the quarter. The company would also pay the accumulated interest at the end of the quarter on the funds borrowed during the quarter. Sales & Collections Production & Materials Conversion Costs Operating Exp Cash Data Income Stmt Depreciation on the building and equipment for the general and administrative offices is budgeted to be $10,000 for the entire quarter, which includes depreciation on new acquisitions. For purposes of the Budget Manufacturing Cost Per Unit calculation Fixed MOH is $.75. The company's income tax rate is projected to be 23% of operating income less interest expense. The company pays $28,000 cash at the end of February in estimated taxes. Particulars Cash Sales Credit Sales (Collected from Previous Month) Total Cash Collections $ S January 36,000 $ 73.500$ 1.09.500 8 February 40,500 $ 84,000 $ 1.24.500 8 March Total 38,700 $ 1,15,200 94,500 $ 2,52,000 1.33.200 8 3.67.200 S $ December 1,05,000 $ 31.500 $ 73.500 $ January 1,20,000 $ 36,000 $ 84,000 $ February March 1,35,000 $ 1,29,000 40,500 $ 38,700 94.500 $ 90,300 S Working Note: Particulars Total Sales Cash Sales (30% x Total Sales) Credit Sales (70% x Total Sales) Part 2 : Production Budget Particulars Sales units Add: Closing inventory Less: Opening Inventory Production units January 8,000 1,800 (1,600) 8,200 February 9,000 1,720 (1,800) 8.920 March 8,600 1,880 (1.720) 8,760 Total 25,600 5.400 (5,120) 25,880 Working Note: Particulars Total Sales for the month Selling price p. Sales units (Total Sales - Selling Price p.) Closing Inventory (20% of Sales units of Following month) Opening inventory (Closing inventory of previous month) December S 1,05,000 $ $ 15$ 7,000 January 1,20,000 $ 15$ 8,000 February 1.35.000 $ 15$ 9,000 March 1,29,000 $ 15$ 8,600 April 1,41,000 15 9,400 1,600 1,800 1,720 1,880 1,360 Not required 1,600 1.800 1,720 1,880 4 4 4 4 Part 3 : Direct Materials Budget Particulars January February March Total Production units (from Part 2) 8,200 8.920 8.760 25.880 Raw material required per unit Total raw material required for production (Units x per unit requirement) (In Pounds) 32,800 35.680 35,040 1,03,320 Closing raw material (15% of next month production) 5.352 5.356 5.328 15.996 Opening raw material inventory 4.920 5.352 5.352 15.624 Materials to be purchases (Materials required for production + Closing RM - Opening RM ) 38,232 35.584 95.016 1,03.832 Purchase price per pound Material purchase cost (Total raw material purchased x Purchase price) 33.292 $ 350784 35.016 $ 1,03.832 Working Note: March : Closing inventory: April Production units = 9.400 +1,360 - 1,880 = 8,880 units April Raw material requirement = 8,880 x 4 = 35.520 units Closing raw material units for March = 15%* 35,520 = 5328 Januaray: Opening Inventory Opening inventory of Jan - Closing inventory of Dec - 15% of Jan production requirement =15% x 32800 = 4920 units $ 1 $ 1 1 $ 1 8 March 35,016 S 8,754 $ 26,688$ Total 1,03,832 25,958 79.362 Part 4 : Cash payments for material purchases Particulars January February Raw material Cost required for production $ 33,232 $ 35,584 | $ 25% paid during the month $ 8,308$ 8,896 $ 75% of previous month expense paid now $ 27.750 $ 24.924 $ * Dec's 75% expense paid in Jan Accounts payable of Dec 31 x 75%-$37,000 x 75% Part 5:Labor Cost Particulars January February Production units (from Part 2) 8,200 8,920 Direct labor hours pou 0.10 Direct labor hours (units x hours p.) 820 892 Wage rate p.h 15$ 15$ Wages paid (Hours worked x Ratep.h) 12.300 $ 13.980 $ Total 25,880 0.10 March 8,760 0.10 876 15$ 13.140 $ 2,588 15 38,820 6. Prepare a cash payments budget for manufacturing overhead costs. 7. Prepare a cash payments budget for operating expenses. 8. Prepare a combined cash budget. 9. Calculate the budgeted manufacturing cost per unit. 10. Prepare a budgeted income statement for the quarter ending March 31Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started