please complete energy and mass balance completely ASAP for a 100% like

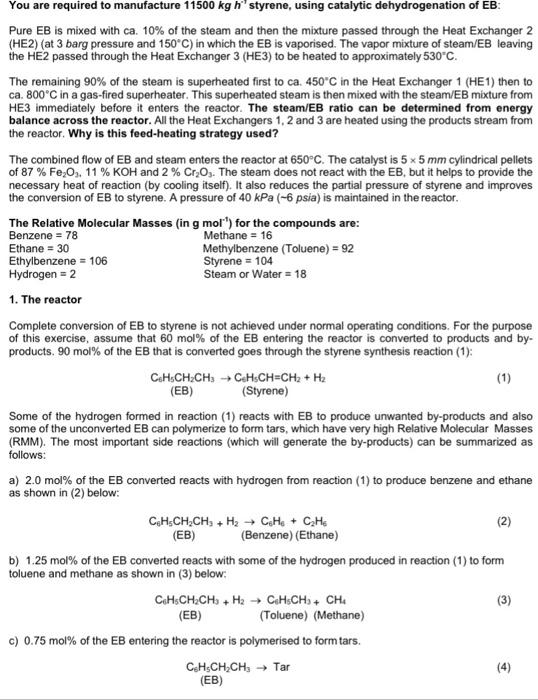

You are required to manufacture 11500 kg h' styrene, using catalytic dehydrogenation of EB: Pure EB is mixed with ca. 10% of the steam and then the mixture passed through the Heat Exchanger 2 (HE2) (at 3 barg pressure and 150C) in which the EB is vaporised. The vapor mixture of steam/EB leaving the HE2 passed through the Heat Exchanger 3 (HE3) to be heated to approximately 530C. The remaining 90% of the steam is superheated first to ca. 450C in the Heat Exchanger 1 (HE1) then to ca. 800C in a gas-fired superheater. This superheated steam is then mixed with the steam/EB mixture from HE3 immediately before it enters the reactor. The steam/EB ratio can be determined from energy balance across the reactor. All the Heat Exchangers 1, 2 and 3 are heated using the products stream from the reactor. Why is this feed-heating strategy used? The combined flow of EB and steam enters the reactor at 650C. The catalyst is 5x5 mm cylindrical pellets of 87 % Fe 03. 11 % KOH and 2 % Cr2Os. The steam does not react with the EB, but it helps to provide the necessary heat of reaction (by cooling itself). It also reduces the partial pressure of styrene and improves the conversion of EB to styrene. A pressure of 40 kPa (-6 psia) is maintained in the reactor. The Relative Molecular Masses (in g mol') for the compounds are: Benzene = 78 Methane = 16 Ethane = 30 Methylbenzene (Toluene) = 92 Ethylbenzene = 106 Styrene = 104 Hydrogen = 2 Steam or Water = 18 1. The reactor Complete conversion of EB to styrene is not achieved under normal operating conditions. For the purpose of this exercise, assume that 60 mol% of the EB entering the reactor is converted to products and by- products. 90 mol% of the EB that is converted goes through the styrene synthesis reaction (1): CeHCH2CH3 CH-CH=CH2 + H2 (1) (EB) (Styrene) Some of the hydrogen formed in reaction (1) reacts with EB to produce unwanted by-products and also some of the unconverted EB can polymerize to form tars, which have very high Relative Molecular Masses (RMM). The most important side reactions (which will generate the by-products) can be summarized as follows: a) 2.0 mol% of the EB converted reacts with hydrogen from reaction (1) to produce benzene and ethane as shown in (2) below: CH,CH,CH, + H2 + C H + CHE (2) (EB) (Benzene) (Ethane) b) 1.25 mol% of the EB converted reacts with some of the hydrogen produced in reaction (1) to form toluene and methane as shown in (3) below: CH:CH-CH3 + H2 C.H.CH) + CHE (3) (Toluene) (Methane) C) 0.75 mol% of the EB entering the reactor is polymerised to form tars. C.HCH.CH, Tar (EB) (EB) 4) You are required to manufacture 11500 kg h' styrene, using catalytic dehydrogenation of EB: Pure EB is mixed with ca. 10% of the steam and then the mixture passed through the Heat Exchanger 2 (HE2) (at 3 barg pressure and 150C) in which the EB is vaporised. The vapor mixture of steam/EB leaving the HE2 passed through the Heat Exchanger 3 (HE3) to be heated to approximately 530C. The remaining 90% of the steam is superheated first to ca. 450C in the Heat Exchanger 1 (HE1) then to ca. 800C in a gas-fired superheater. This superheated steam is then mixed with the steam/EB mixture from HE3 immediately before it enters the reactor. The steam/EB ratio can be determined from energy balance across the reactor. All the Heat Exchangers 1, 2 and 3 are heated using the products stream from the reactor. Why is this feed-heating strategy used? The combined flow of EB and steam enters the reactor at 650C. The catalyst is 5x5 mm cylindrical pellets of 87 % Fe 03. 11 % KOH and 2 % Cr2Os. The steam does not react with the EB, but it helps to provide the necessary heat of reaction (by cooling itself). It also reduces the partial pressure of styrene and improves the conversion of EB to styrene. A pressure of 40 kPa (-6 psia) is maintained in the reactor. The Relative Molecular Masses (in g mol') for the compounds are: Benzene = 78 Methane = 16 Ethane = 30 Methylbenzene (Toluene) = 92 Ethylbenzene = 106 Styrene = 104 Hydrogen = 2 Steam or Water = 18 1. The reactor Complete conversion of EB to styrene is not achieved under normal operating conditions. For the purpose of this exercise, assume that 60 mol% of the EB entering the reactor is converted to products and by- products. 90 mol% of the EB that is converted goes through the styrene synthesis reaction (1): CeHCH2CH3 CH-CH=CH2 + H2 (1) (EB) (Styrene) Some of the hydrogen formed in reaction (1) reacts with EB to produce unwanted by-products and also some of the unconverted EB can polymerize to form tars, which have very high Relative Molecular Masses (RMM). The most important side reactions (which will generate the by-products) can be summarized as follows: a) 2.0 mol% of the EB converted reacts with hydrogen from reaction (1) to produce benzene and ethane as shown in (2) below: CH,CH,CH, + H2 + C H + CHE (2) (EB) (Benzene) (Ethane) b) 1.25 mol% of the EB converted reacts with some of the hydrogen produced in reaction (1) to form toluene and methane as shown in (3) below: CH:CH-CH3 + H2 C.H.CH) + CHE (3) (Toluene) (Methane) C) 0.75 mol% of the EB entering the reactor is polymerised to form tars. C.HCH.CH, Tar (EB) (EB) 4)