Answered step by step

Verified Expert Solution

Question

1 Approved Answer

please help it's agent there is an update Lactic Ltd. (Lactic) is a cream and butter manufacturer. The entity has a 30 November financial year-end

please help it's agent

there is an update

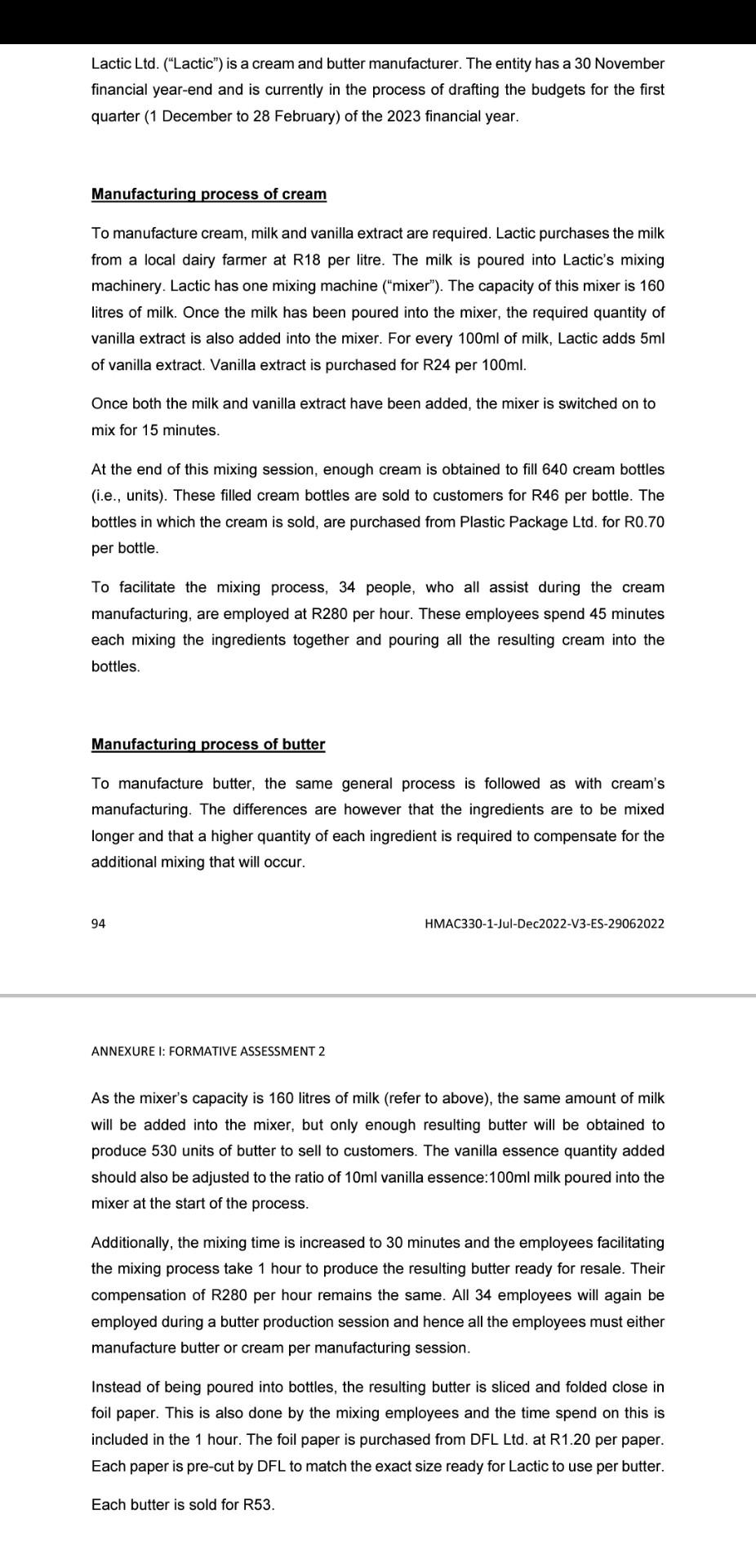

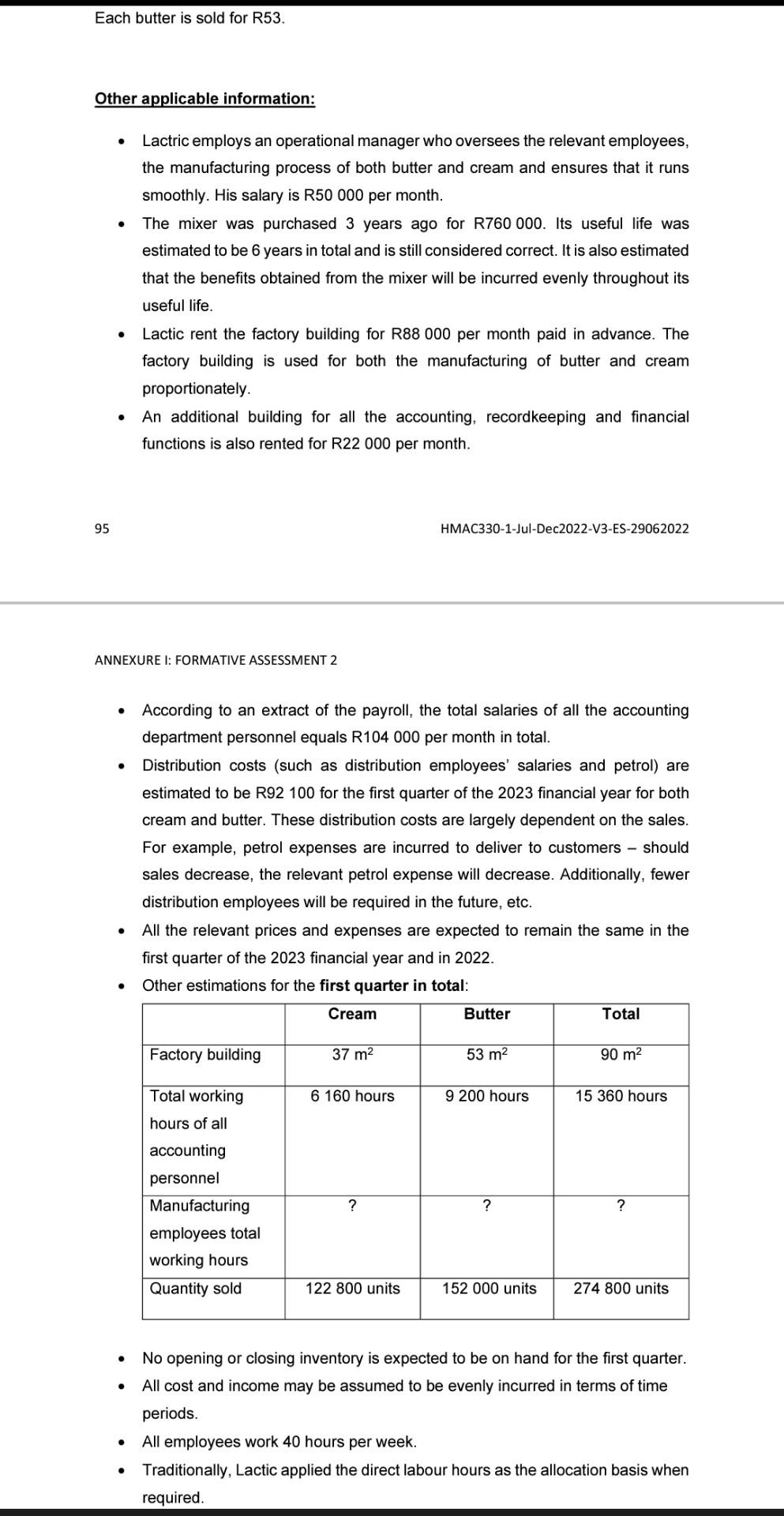

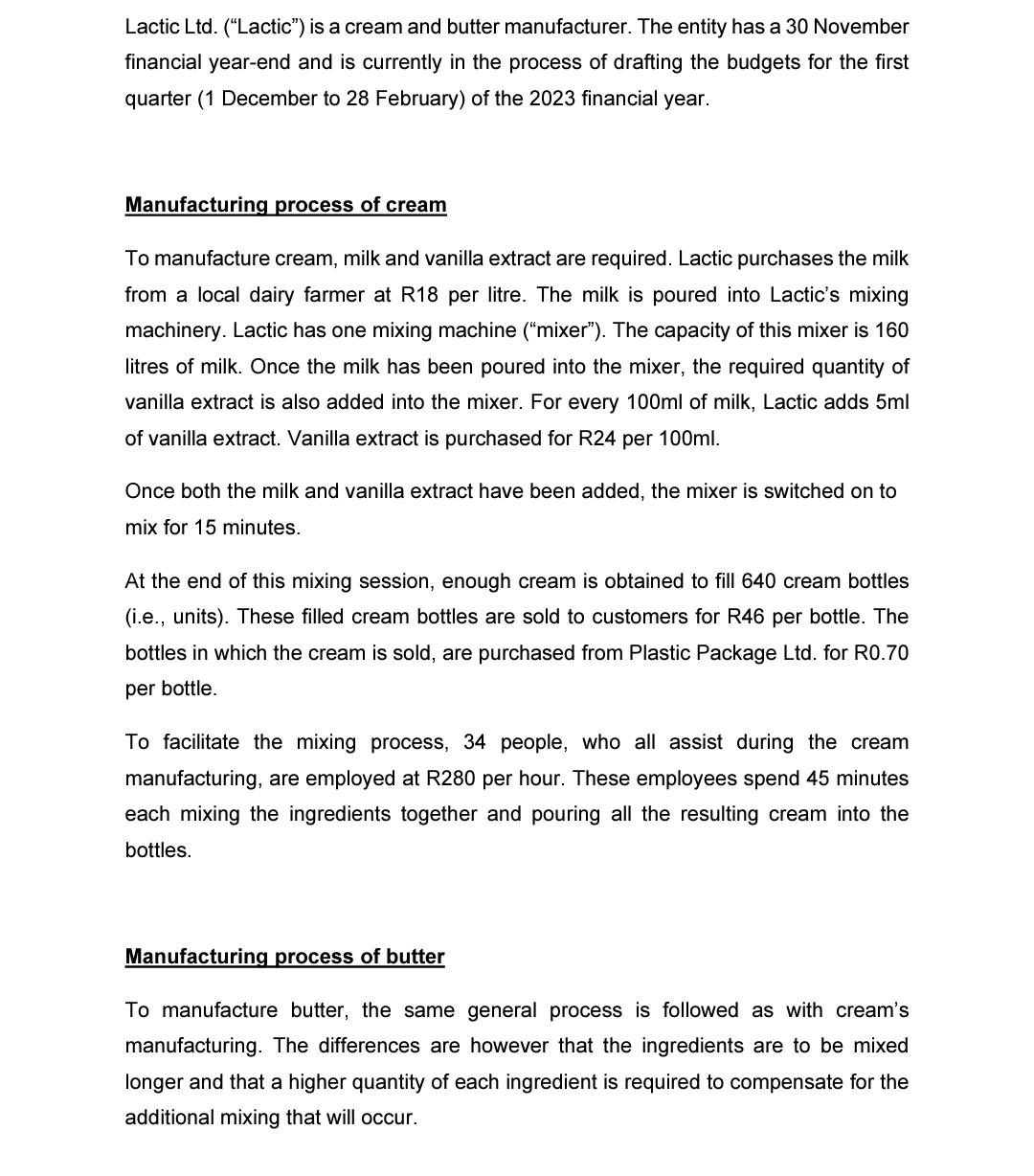

Lactic Ltd. ("Lactic") is a cream and butter manufacturer. The entity has a 30 November financial year-end and is currently in the process of drafting the budgets for the first quarter (1 December to 28 February) of the 2023 financial year. Manufacturing process of cream To manufacture cream, milk and vanilla extract are required. Lactic purchases the milk from a local dairy farmer at R18 per litre. The milk is poured into Lactic's mixing machinery. Lactic has one mixing machine ("mixer"). The capacity of this mixer is 160 litres of milk. Once the milk has been poured into the mixer, the required quantity of vanilla extract is also added into the mixer. For every 100ml of milk, Lactic adds 5ml of vanilla extract. Vanilla extract is purchased for R24 per 100ml. Once both the milk and vanilla extract have been added, the mixer is switched on to mix for 15 minutes. At the end of this mixing session, enough cream is obtained to fill 640 cream bottles (i.e., units). These filled cream bottles are sold to customers for R46 per bottle. The bottles in which the cream is sold, are purchased from Plastic Package Ltd. for R0.70 per bottle. To facilitate the mixing process, 34 people, who all assist during the cream manufacturing, are employed at R280 per hour. These employees spend 45 minutes each mixing the ingredients together and pouring all the resulting cream into the bottles. Manufacturing process of butter To manufacture butter, the same general process is followed as with cream's manufacturing. The differences are however that the ingredients are to be mixed Ionger and that a higher quantity of each ingredient is required to compensate for the additional mixing that will occur. 94 HMAC330-1-Jul-Dec2022-V3-ES-29062022 ANNEXURE I: FORMATIVE ASSESSMENT 2 As the mixer's capacity is 160 litres of milk (refer to above), the same amount of milk will be added into the mixer, but only enough resulting butter will be obtained to produce 530 units of butter to sell to customers. The vanilla essence quantity added should also be adjusted to the ratio of 10ml vanilla essence: 100ml milk poured into the mixer at the start of the process. Additionally, the mixing time is increased to 30 minutes and the employees facilitating the mixing process take 1 hour to produce the resulting butter ready for resale. Their compensation of R280 per hour remains the same. All 34 employees will again be employed during a butter production session and hence all the employees must either manufacture butter or cream per manufacturing session. Instead of being poured into bottles, the resulting butter is sliced and folded close in foil paper. This is also done by the mixing employees and the time spend on this is included in the 1 hour. The foil paper is purchased from DFL Ltd. at R1.20 per paper. Each paper is pre-cut by DFL to match the exact size ready for Lactic to use per butter. Each butter is sold for R53. Other applicable information: - Lactric employs an operational manager who oversees the relevant employees, the manufacturing process of both butter and cream and ensures that it runs smoothly. His salary is R50 000 per month. - The mixer was purchased 3 years ago for R760000. Its useful life was estimated to be 6 years in total and is still considered correct. It is also estimated that the benefits obtained from the mixer will be incurred evenly throughout its useful life. - Lactic rent the factory building for R88 000 per month paid in advance. The factory building is used for both the manufacturing of butter and cream proportionately. - An additional building for all the accounting, recordkeeping and financial functions is also rented for R22000 per month. 95 HMAC330-1-Jul-Dec2022-V3-ES-29062022 ANNEXURE I: FORMATIVE ASSESSMENT 2 - According to an extract of the payroll, the total salaries of all the accounting department personnel equals R104000 per month in total. - Distribution costs (such as distribution employees' salaries and petrol) are estimated to be R92 100 for the first quarter of the 2023 financial year for both cream and butter. These distribution costs are largely dependent on the sales. For example, petrol expenses are incurred to deliver to customers - should sales decrease, the relevant petrol expense will decrease. Additionally, fewer distribution employees will be required in the future, etc. - All the relevant prices and expenses are expected to remain the same in the first quarter of the 2023 financial year and in 2022. - Other estimations for the first quarter in total: - No opening or closing inventory is expected to be on hand for the first quarter. - All cost and income may be assumed to be evenly incurred in terms of time periods. - All employees work 40 hours per week. - Traditionally, Lactic applied the direct labour hours as the allocation basis when required. Required: 1.1) Draft the following budgets for the first quarter of Lactic Ltd.'s 2023 financial year: - Direct material usage budget per final product type (i.e. separately for cream and butter) (17 marks) - Direct labour budget (8 marks) - Factory manufacturing overhead budget (9 marks) Lactic Ltd. ("Lactic") is a cream and butter manufacturer. The entity has a 30 November financial year-end and is currently in the process of drafting the budgets for the first quarter (1 December to 28 February) of the 2023 financial year. Manufacturing process of cream To manufacture cream, milk and vanilla extract are required. Lactic purchases the milk from a local dairy farmer at R18 per litre. The milk is poured into Lactic's mixing machinery. Lactic has one mixing machine ("mixer"). The capacity of this mixer is 160 litres of milk. Once the milk has been poured into the mixer, the required quantity of vanilla extract is also added into the mixer. For every 100ml of milk, Lactic adds 5ml of vanilla extract. Vanilla extract is purchased for R24 per 100ml. Once both the milk and vanilla extract have been added, the mixer is switched on to mix for 15 minutes. At the end of this mixing session, enough cream is obtained to fill 640 cream bottles (i.e., units). These filled cream bottles are sold to customers for R46 per bottle. The bottles in which the cream is sold, are purchased from Plastic Package Ltd. for R0.70 per bottle. To facilitate the mixing process, 34 people, who all assist during the cream manufacturing, are employed at 280 per hour. These employees spend 45 minutes each mixing the ingredients together and pouring all the resulting cream into the bottles. Manufacturing process of butter To manufacture butter, the same general process is followed as with cream's manufacturing. The differences are however that the ingredients are to be mixed Ionger and that a higher quantity of each ingredient is required to compensate for the additional mixing that will occur. As the mixer's capacity is 160 litres of milk (refer to above), the same amount of milk will be added into the mixer, but only enough resulting butter will be obtained to produce 530 units of butter to sell to customers. The vanilla essence quantity added should also be adjusted to the ratio of 10ml vanilla essence: 100ml milk poured into the mixer at the start of the process. Additionally, the mixing time is increased to 30 minutes and the employees facilitating the mixing process take 1 hour to produce the resulting butter ready for resale. Their compensation of R280 per hour remains the same. All 34 employees will again be employed during a butter production session and hence all the employees must either manufacture butter or cream per manufacturing session. Instead of being poured into bottles, the resulting butter is sliced and folded close in foil paper. This is also done by the mixing employees and the time spend on this is included in the 1 hour. The foil paper is purchased from DFL Ltd. at R1.20 per paper. Each paper is pre-cut by DFL to match the exact size ready for Lactic to use per butter. Each butter is sold for R53. Other applicable information: - Lactric employs an operational manager who oversees the relevant employees, the manufacturing process of both butter and cream and ensures that it runs smoothly. His salary is R50 000 per month. - The mixer was purchased 3 years ago for R760000. Its useful life was estimated to be 6 years in total and is still considered correct. It is also estimated that the benefits obtained from the mixer will be incurred evenly throughout its useful life. - Lactic rent the factory building for R88 000 per month paid in advance. The factory building is used for both the manufacturing of butter and cream proportionately. - An additional building for all the accounting, recordkeeping and financial functions is also rented for R22 000 per month. - According to an extract of the payroll, the total salaries of all the accounting department personnel equals R104 000 per month in total. - Distribution costs (such as distribution employees' salaries and petrol) are estimated to be R92 100 for the first quarter of the 2023 financial year for both cream and butter. These distribution costs are largely dependent on the sales. For example, petrol expenses are incurred to deliver to customers - should sales decrease, the relevant petrol expense will decrease. Additionally, fewer distribution employees will be required in the future, etc. - All the relevant prices and expenses are expected to remain the same in the first quarter of the 2023 financial year and in 2022. - Other estimations for the first auarter in total: - No opening or closing inventory is expected to be on hand for the first quarter. - All cost and income may be assumed to be evenly incurred in terms of time periods. - All employees work 40 hours per week. - Traditionally, Lactic applied the direct labour hours as the allocation basis when required. 96 HMAC330-1-Jul-Dec2022-V3-ES-29062022 ANNEXURE I: FORMATIVE ASSESSMENT 2 Required: 1.1) Draft the following budgets for the first quarter of Lactic Ltd.'s 2023 financial year: - Direct material usage budget per final product type (i.e. separately for cream and butter) (17 marks) Lactic Ltd. ("Lactic") is a cream and butter manufacturer. The entity has a 30 November financial year-end and is currently in the process of drafting the budgets for the first quarter (1 December to 28 February) of the 2023 financial year. Manufacturing process of cream To manufacture cream, milk and vanilla extract are required. Lactic purchases the milk from a local dairy farmer at R18 per litre. The milk is poured into Lactic's mixing machinery. Lactic has one mixing machine ("mixer"). The capacity of this mixer is 160 litres of milk. Once the milk has been poured into the mixer, the required quantity of vanilla extract is also added into the mixer. For every 100ml of milk, Lactic adds 5ml of vanilla extract. Vanilla extract is purchased for R24 per 100ml. Once both the milk and vanilla extract have been added, the mixer is switched on to mix for 15 minutes. At the end of this mixing session, enough cream is obtained to fill 640 cream bottles (i.e., units). These filled cream bottles are sold to customers for R46 per bottle. The bottles in which the cream is sold, are purchased from Plastic Package Ltd. for R0.70 per bottle. To facilitate the mixing process, 34 people, who all assist during the cream manufacturing, are employed at R280 per hour. These employees spend 45 minutes each mixing the ingredients together and pouring all the resulting cream into the bottles. Manufacturing process of butter To manufacture butter, the same general process is followed as with cream's manufacturing. The differences are however that the ingredients are to be mixed Ionger and that a higher quantity of each ingredient is required to compensate for the additional mixing that will occur. 94 HMAC330-1-Jul-Dec2022-V3-ES-29062022 ANNEXURE I: FORMATIVE ASSESSMENT 2 As the mixer's capacity is 160 litres of milk (refer to above), the same amount of milk will be added into the mixer, but only enough resulting butter will be obtained to produce 530 units of butter to sell to customers. The vanilla essence quantity added should also be adjusted to the ratio of 10ml vanilla essence: 100ml milk poured into the mixer at the start of the process. Additionally, the mixing time is increased to 30 minutes and the employees facilitating the mixing process take 1 hour to produce the resulting butter ready for resale. Their compensation of R280 per hour remains the same. All 34 employees will again be employed during a butter production session and hence all the employees must either manufacture butter or cream per manufacturing session. Instead of being poured into bottles, the resulting butter is sliced and folded close in foil paper. This is also done by the mixing employees and the time spend on this is included in the 1 hour. The foil paper is purchased from DFL Ltd. at R1.20 per paper. Each paper is pre-cut by DFL to match the exact size ready for Lactic to use per butter. Each butter is sold for R53. Other applicable information: - Lactric employs an operational manager who oversees the relevant employees, the manufacturing process of both butter and cream and ensures that it runs smoothly. His salary is R50 000 per month. - The mixer was purchased 3 years ago for R760000. Its useful life was estimated to be 6 years in total and is still considered correct. It is also estimated that the benefits obtained from the mixer will be incurred evenly throughout its useful life. - Lactic rent the factory building for R88 000 per month paid in advance. The factory building is used for both the manufacturing of butter and cream proportionately. - An additional building for all the accounting, recordkeeping and financial functions is also rented for R22000 per month. 95 HMAC330-1-Jul-Dec2022-V3-ES-29062022 ANNEXURE I: FORMATIVE ASSESSMENT 2 - According to an extract of the payroll, the total salaries of all the accounting department personnel equals R104000 per month in total. - Distribution costs (such as distribution employees' salaries and petrol) are estimated to be R92 100 for the first quarter of the 2023 financial year for both cream and butter. These distribution costs are largely dependent on the sales. For example, petrol expenses are incurred to deliver to customers - should sales decrease, the relevant petrol expense will decrease. Additionally, fewer distribution employees will be required in the future, etc. - All the relevant prices and expenses are expected to remain the same in the first quarter of the 2023 financial year and in 2022. - Other estimations for the first quarter in total: - No opening or closing inventory is expected to be on hand for the first quarter. - All cost and income may be assumed to be evenly incurred in terms of time periods. - All employees work 40 hours per week. - Traditionally, Lactic applied the direct labour hours as the allocation basis when required. Required: 1.1) Draft the following budgets for the first quarter of Lactic Ltd.'s 2023 financial year: - Direct material usage budget per final product type (i.e. separately for cream and butter) (17 marks) - Direct labour budget (8 marks) - Factory manufacturing overhead budget (9 marks) Lactic Ltd. ("Lactic") is a cream and butter manufacturer. The entity has a 30 November financial year-end and is currently in the process of drafting the budgets for the first quarter (1 December to 28 February) of the 2023 financial year. Manufacturing process of cream To manufacture cream, milk and vanilla extract are required. Lactic purchases the milk from a local dairy farmer at R18 per litre. The milk is poured into Lactic's mixing machinery. Lactic has one mixing machine ("mixer"). The capacity of this mixer is 160 litres of milk. Once the milk has been poured into the mixer, the required quantity of vanilla extract is also added into the mixer. For every 100ml of milk, Lactic adds 5ml of vanilla extract. Vanilla extract is purchased for R24 per 100ml. Once both the milk and vanilla extract have been added, the mixer is switched on to mix for 15 minutes. At the end of this mixing session, enough cream is obtained to fill 640 cream bottles (i.e., units). These filled cream bottles are sold to customers for R46 per bottle. The bottles in which the cream is sold, are purchased from Plastic Package Ltd. for R0.70 per bottle. To facilitate the mixing process, 34 people, who all assist during the cream manufacturing, are employed at 280 per hour. These employees spend 45 minutes each mixing the ingredients together and pouring all the resulting cream into the bottles. Manufacturing process of butter To manufacture butter, the same general process is followed as with cream's manufacturing. The differences are however that the ingredients are to be mixed Ionger and that a higher quantity of each ingredient is required to compensate for the additional mixing that will occur. As the mixer's capacity is 160 litres of milk (refer to above), the same amount of milk will be added into the mixer, but only enough resulting butter will be obtained to produce 530 units of butter to sell to customers. The vanilla essence quantity added should also be adjusted to the ratio of 10ml vanilla essence: 100ml milk poured into the mixer at the start of the process. Additionally, the mixing time is increased to 30 minutes and the employees facilitating the mixing process take 1 hour to produce the resulting butter ready for resale. Their compensation of R280 per hour remains the same. All 34 employees will again be employed during a butter production session and hence all the employees must either manufacture butter or cream per manufacturing session. Instead of being poured into bottles, the resulting butter is sliced and folded close in foil paper. This is also done by the mixing employees and the time spend on this is included in the 1 hour. The foil paper is purchased from DFL Ltd. at R1.20 per paper. Each paper is pre-cut by DFL to match the exact size ready for Lactic to use per butter. Each butter is sold for R53. Other applicable information: - Lactric employs an operational manager who oversees the relevant employees, the manufacturing process of both butter and cream and ensures that it runs smoothly. His salary is R50 000 per month. - The mixer was purchased 3 years ago for R760000. Its useful life was estimated to be 6 years in total and is still considered correct. It is also estimated that the benefits obtained from the mixer will be incurred evenly throughout its useful life. - Lactic rent the factory building for R88 000 per month paid in advance. The factory building is used for both the manufacturing of butter and cream proportionately. - An additional building for all the accounting, recordkeeping and financial functions is also rented for R22 000 per month. - According to an extract of the payroll, the total salaries of all the accounting department personnel equals R104 000 per month in total. - Distribution costs (such as distribution employees' salaries and petrol) are estimated to be R92 100 for the first quarter of the 2023 financial year for both cream and butter. These distribution costs are largely dependent on the sales. For example, petrol expenses are incurred to deliver to customers - should sales decrease, the relevant petrol expense will decrease. Additionally, fewer distribution employees will be required in the future, etc. - All the relevant prices and expenses are expected to remain the same in the first quarter of the 2023 financial year and in 2022. - Other estimations for the first auarter in total: - No opening or closing inventory is expected to be on hand for the first quarter. - All cost and income may be assumed to be evenly incurred in terms of time periods. - All employees work 40 hours per week. - Traditionally, Lactic applied the direct labour hours as the allocation basis when required. 96 HMAC330-1-Jul-Dec2022-V3-ES-29062022 ANNEXURE I: FORMATIVE ASSESSMENT 2 Required: 1.1) Draft the following budgets for the first quarter of Lactic Ltd.'s 2023 financial year: - Direct material usage budget per final product type (i.e. separately for cream and butter) (17 marks)Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started