Answered step by step

Verified Expert Solution

Question

1 Approved Answer

please reply asap Case Study: Will Win, Director, Quality Assurance Will Win was whistling as be walked toward his office, still feeling a bit hike

please reply asap

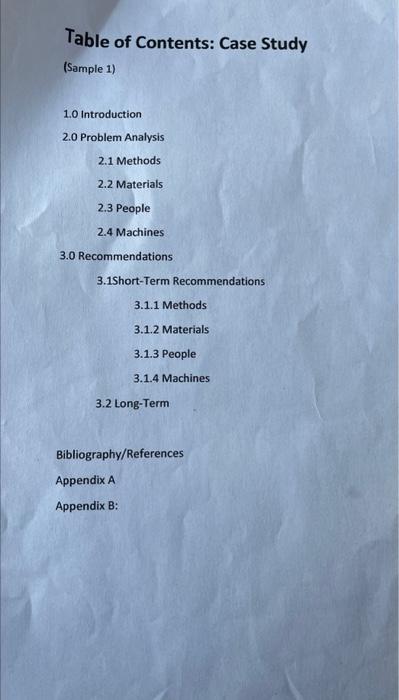

Case Study: Will Win, Director, Quality Assurance Will Win was whistling as be walked toward his office, still feeling a bit hike a stranger suince be had been hired four weeks ago as diroctor, quality assurance. All last week be had been awsy from the plant at an interesting seminar entitled "Quality in the 2020's" given for quality managers of masufacturing plants by the conporate training department. He was not looking forward to really digging into the quality problem at this industrial products plant employing? 1967 people. WiIl poked his bead into Rob Roben's office, his immediate subordinate, the quality control manager, and asked him how things had gone last woek. Rob's muted smile and an "Oh fine" stopped Will in his tracks. He did not know Rob very well and was unsure of how to start building his relationship with him sinee Rob had been passed over for the promotion of Will's job - Rob's evaluation form had stated "superb tochnical knowledges matagerial skilly lacking" Will decided to inquire a litile further into what had happened. Rob repliod. Oh, just another typical quality snafu. We had little problem on the Greasex line last Week (a specializod degreasing solvent packed in a spray can for the high-technology sector). A little high prescure was found on some of the cans on the second shift, but a supervisor vented them out to that we could ship them out. We met our delivery schedule! Since Will was still relatively unfamiliar with the plant and the prodacts, be anked Rob to claborate. Painfally, Rob continued: We've been having some trouble with the new filling equipenent, and some of the cans were pressurized beyond our acceptable standard on a psi (pounds per square inch) rating scale. The production rate is still 50 percent of standard, about 14 cases per shitt, and we caught it balfway into the shift. Cody Cook (the inspector for that line) picked it up. tagged the cases "Hold" and went on about his dutics. When be returned at the end of the shift to write up the rejects. Mat Mason, first-line supervisor, was by a pallet of finished goods finishing sealing up a carton of the rejected Greasex: the reject "Hold" tags had been removed. He told Cody Cook that be had heard about the high pressure from another inspector at the coffee break, had come back, taken off the tass, individually turned the cans upside down and vented every one of them in the rejected cight cartons: He told Cody Cook that production planning was really pashing for the stuff, and that they couldn't delay by having it sent through the rework area. He told Cody Cook that be would get on the operator to run the equipment right next time. Cody Cook didn't write it up but came in about three days ago to tell me about it. Oh, it happens every once in a while, and I told him to make sure to chock with maintenance to make sure the filling machine was adjusted; and I saw Mat in the hall and told him that he ought to send the stuff through rework nekt time. The incideat had oecurred a week ago: the goods wero probably oest in the customer's hands by now; everyone had forgotten about it (or wanted to!) s and there seemed to be more pressing problems than this for Will to spend his time on. However, this ocatinued to nag at bien. He felt like the quality department was being treated as a joke, and it also felt to him like a personal slap from manufacturing. He did not want to start a war with the prodoction people but what coold he do? He was troubled enough to cancel his appointments and spend the morning talking to a few people. After a long and very tactful moming he learnod the following: A. From personnel - The operator for the fitling equipment had just been transferred from shipping two weeks ago. He had no formal training in this job but was being trainod by Mat on the job, to run the equipment. When Cody Cook had tested the high pressure cans, the operator was nowhere to be found and had only learned of the rejected material from Mat after the shift was over. B. From plant maiatenance - This particular picce of automated filling equipment had been parchased two years ago for use on another product. It had been swithed to the Greasex line six months ago, and maintenance had 13 work orders during the last months for repairs or adjustments on it. The equipment had been adapted by phant maintenance for handling the lower viscosity Greasex, which it had not originally been designed for. This included designing a special filling head. There was no scheduled preventative maintenance for this equipment, and the parts for the sensitive filling head, reploced three tumes in the last six months, had to be made at a nearty machine shop. Nonstandard downtime was running at 19% of actual running times. C. From purchasing - The plastic noule heads for the Greasex can, recently designed by a vendor for this new product on a rush order, were often found with shght burrs on the inside rim, and this causod some trouble in fitting the top to the can. An increase in application pressure at the filling head by maintenance adjustment had solved the bert application problem or had at least "forced" the novele heads on despite the burm. Purchasing said that they were going to talk to the sales representative of the nozale supplicr about this next time they came in. D. From product design and packaging - The can, designed especially for Greasex, had been contoured to allow better gripping by the user. This change, instigated by marketing research, set Gireasex apart from tho appearance of its competitors and was seen by the designers to be "significant." There had been no test of the effects of the contoured can. on filling speed or filling hydrodynamies from a high-pressured filling head. Will had a hunch that the new design, was acting as a venturi when being filled, but the packaging designer thought that "unlikely." F. From the manufacturing manager - He had lieard about the problem: in fact, Mex had made a joke about it, bragging about how he beat his production quota to the other foremen and shin supervisoes. Mat was thought of by the manuficturas manager to be one of the "best foremen we have... be always gets his production out." His promotion papers were actually on the manufacturing magager' 's desk when Will dropped by. Mat was being "strongly considered for promotion to shift supervisor. The manafacturing manager, ander pressure from Mr. Power for cost improvements and reduced delivery times, sympathized with Will but said that the rework area would have just vented with their presure gauges what Mat did by hand. "But, I'll speak with Mat about the incident." F. From Marketing - The introduction of Greasex had been nushed to beat competitors to market and a major promotional/advertising campaign was now underway to increase consumer awareness. A deluge of orders is swamping the order-taking department and patting Greasex high on the back-order list. Production "had to furn the stuff out." Even a little off spec was tolerable because "it would be better to have it on the shelf than not there at all. Who cares if the label is a little crooked or the stuff comes out with a linle too much pressure? We need market share now in that high-tech segment." What bothered Will the most was the safety issue of the high-pressure in the cans, He had no way of knowing how much of a hazard the high pressure was or if Mat had vented them enough to effectively reduce the hazard. The data from the can manufacturer which Rob had showod him indicated that the high pressure which the inspector had found was not in the danger area; but then again the inspector had only used a sample testing procedure to reject the eight cases. Even if he could morally accept that there was no product safety hamard, could he make sure that this nover happened again? Will, skipping lunch, sat in his office and thought about the morning's events. Last woek's scminar had talked about "the nole of quality", "productivity and quality", "creating a new attitude", and the "quality challenge", but where had they told him what to do when this happens? He had left a very good job to come here becatse he thought the company was scrious about the importance or quality, and be wanted a challenge. Will demanded and received salary equal to the manufacturiag, marketing and RED directors' and reported directly to the General Manager. Yet he still did not know exactly what he should or should not do or even what be could or could not do. Provocative questions to help get you started: 1. What is wrong with the way quality is managed in this company? 2. What should be done to improve quality management? 3. What should Will Win do? Page 3 of 3 Table of Contents: Case Study (Sample 1) 1.0 introduction 2.0 Problem Analysis 2.1 Methods 2.2 Materials 2.3 People 2.4 Machines 3.0 Recommendations 3.1Short-Term Recommendations 3.1.1 Methods 3.1.2 Materials 3.1.3 People 3.1.4 Machines 3.2 Long-Term Bibliography/References Appendix A Appendix B

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started