Answered step by step

Verified Expert Solution

Question

1 Approved Answer

PLEASE SHOW ALL FORMULAS A Canadian chocolate and candy confectionary company name Burdees operates Distribution Centers for finished goods in three cities across Canada: Mississauga,

PLEASE SHOW ALL FORMULAS

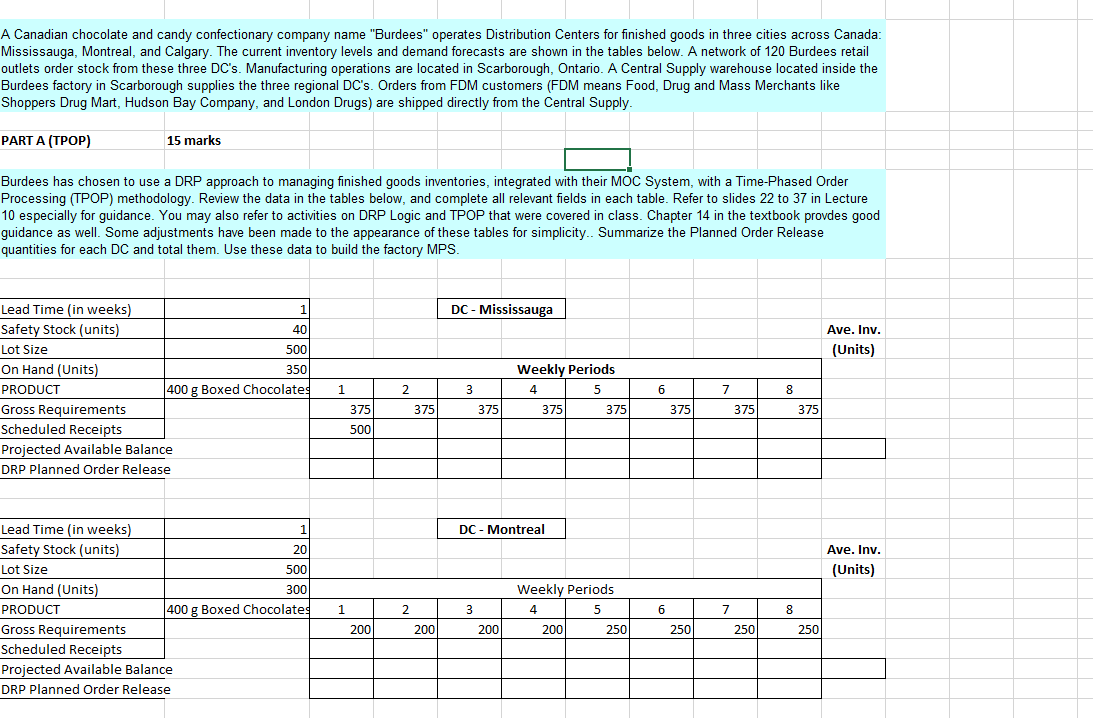

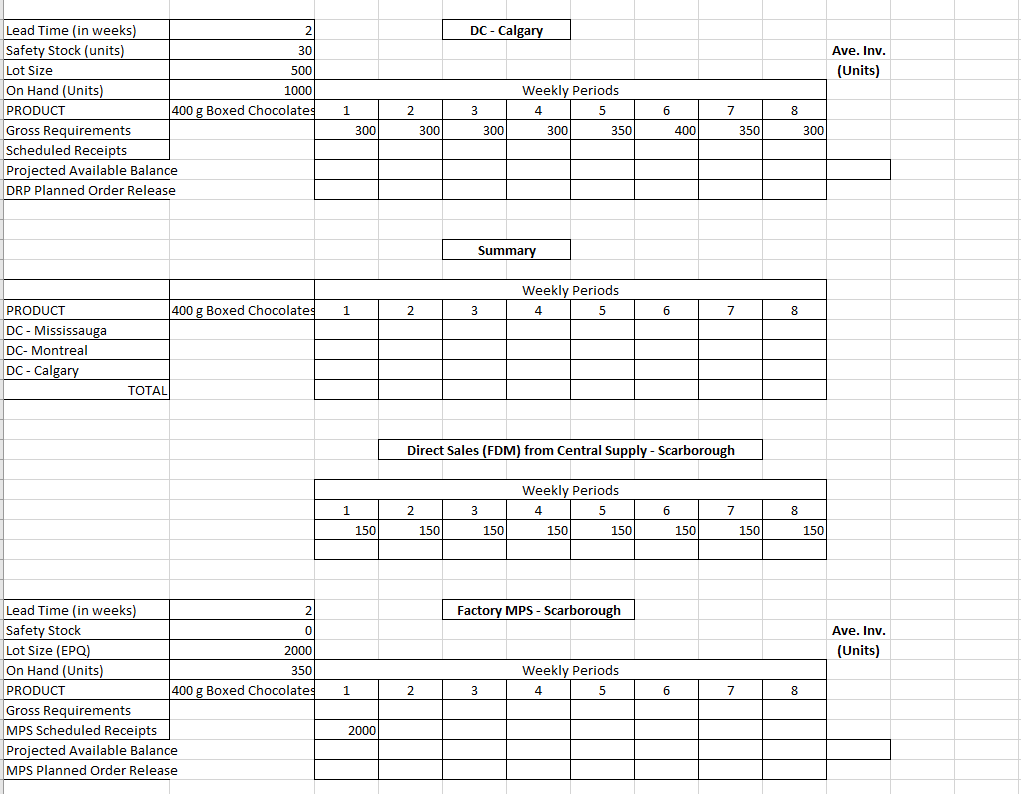

A Canadian chocolate and candy confectionary company name "Burdees" operates Distribution Centers for finished goods in three cities across Canada: Mississauga, Montreal, and Calgary. The current inventory levels and demand forecasts are shown in the tables below. A network of 120 Burdees retail outlets order stock from these three DC's. Manufacturing operations are located in Scarborough, Ontario. A Central Supply warehouse located inside the Burdees factory in Scarborough supplies the three regional DC's. Orders from FDM customers (FDM means Food, Drug and Mass Merchants like Shoppers Drug Mart, Hudson Bay Company, and London Drugs) are shipped directly from the Central Supply. PART A (TPOP) 15 marks Burdees has chosen to use a DRP approach to managing finished goods inventories, integrated with their MOC System, with a Time-Phased Order Processing (TPOP) methodology. Review the data in the tables below, and complete all relevant fields in each table. Refer to slides 22 to 37 in Lecture 10 especially for guidance. You may also refer to activities on DRP Logic and TPOP that were covered in class. Chapter 14 in the textbook provdes good guidance as well. Some adjustments have been made to the appearance of these tables for simplicity. Summarize the Planned Order Release quantities for each DC and total them. Use these data to build the factory MPS. DC - Mississauga Ave. Inv. (Units) Lead Time (in weeks) Safety Stock (units) Lot Size 500 On Hand (Units) 350 PRODUCT 400 g Boxed Chocolates Gross Requirements Scheduled Receipts Projected Available Balance DRP Planned Order Release Weekly Periods 5 2 3 6 6 7 8 375 375 375 375 375 375 375 375 500 441101111 MT DC - Montreal Ave. Inv. (Units) Lead Time (in weeks) 1 Safety Stock (units) 20 Lot Size 500 On Hand (Units) 300 PRODUCT 400 g Boxed Chocolate Gross Requirements Scheduled Receipts Projected Available Balance DRP Planned Order Release 1 2 3 3 Weekly Periods 4 5 200 250 6 8 7 250 200 200 200 250 250 DC - Calgary Ave. Inv. (Units) Lead Time (in weeks) 2 Safety Stock (units) 30 Lot Size 5001 On Hand (Units) 1000 PRODUCT 400 g Boxed Chocolates Gross Requirements Scheduled Receipts Projected Available Balance DRP Planned Order Release 1 2 3 Weekly Periods 4 5 300 350 6 7 8 300 300 300 4001 350 300 Summary Weekly Periods 4 5 400 g Boxed Chocolates 1 2 3 6 7 8 PRODUCT DC - Mississauga DC- Montreal DC - Calgary TOTAL Direct Sales (FDM) from Central Supply - Scarborough Weekly Periods 4 5 1 2 3 6 7 8 150 150 150 150 150 150 150 150 Factory MPS - Scarborough Ave. Inv. (Units) Lead Time (in weeks) 2 Safety Stock 0 Lot Size (EPO) 2000 On Hand (Units) 3501 PRODUCT 400 g Boxed Chocolates Gross Requirements MPS Scheduled Receipts Projected Available Balance MPS Planned Order Release Weekly Periods 4 5 1 2 3 6 7 8 2000 A Canadian chocolate and candy confectionary company name "Burdees" operates Distribution Centers for finished goods in three cities across Canada: Mississauga, Montreal, and Calgary. The current inventory levels and demand forecasts are shown in the tables below. A network of 120 Burdees retail outlets order stock from these three DC's. Manufacturing operations are located in Scarborough, Ontario. A Central Supply warehouse located inside the Burdees factory in Scarborough supplies the three regional DC's. Orders from FDM customers (FDM means Food, Drug and Mass Merchants like Shoppers Drug Mart, Hudson Bay Company, and London Drugs) are shipped directly from the Central Supply. PART A (TPOP) 15 marks Burdees has chosen to use a DRP approach to managing finished goods inventories, integrated with their MOC System, with a Time-Phased Order Processing (TPOP) methodology. Review the data in the tables below, and complete all relevant fields in each table. Refer to slides 22 to 37 in Lecture 10 especially for guidance. You may also refer to activities on DRP Logic and TPOP that were covered in class. Chapter 14 in the textbook provdes good guidance as well. Some adjustments have been made to the appearance of these tables for simplicity. Summarize the Planned Order Release quantities for each DC and total them. Use these data to build the factory MPS. DC - Mississauga Ave. Inv. (Units) Lead Time (in weeks) Safety Stock (units) Lot Size 500 On Hand (Units) 350 PRODUCT 400 g Boxed Chocolates Gross Requirements Scheduled Receipts Projected Available Balance DRP Planned Order Release Weekly Periods 5 2 3 6 6 7 8 375 375 375 375 375 375 375 375 500 441101111 MT DC - Montreal Ave. Inv. (Units) Lead Time (in weeks) 1 Safety Stock (units) 20 Lot Size 500 On Hand (Units) 300 PRODUCT 400 g Boxed Chocolate Gross Requirements Scheduled Receipts Projected Available Balance DRP Planned Order Release 1 2 3 3 Weekly Periods 4 5 200 250 6 8 7 250 200 200 200 250 250 DC - Calgary Ave. Inv. (Units) Lead Time (in weeks) 2 Safety Stock (units) 30 Lot Size 5001 On Hand (Units) 1000 PRODUCT 400 g Boxed Chocolates Gross Requirements Scheduled Receipts Projected Available Balance DRP Planned Order Release 1 2 3 Weekly Periods 4 5 300 350 6 7 8 300 300 300 4001 350 300 Summary Weekly Periods 4 5 400 g Boxed Chocolates 1 2 3 6 7 8 PRODUCT DC - Mississauga DC- Montreal DC - Calgary TOTAL Direct Sales (FDM) from Central Supply - Scarborough Weekly Periods 4 5 1 2 3 6 7 8 150 150 150 150 150 150 150 150 Factory MPS - Scarborough Ave. Inv. (Units) Lead Time (in weeks) 2 Safety Stock 0 Lot Size (EPO) 2000 On Hand (Units) 3501 PRODUCT 400 g Boxed Chocolates Gross Requirements MPS Scheduled Receipts Projected Available Balance MPS Planned Order Release Weekly Periods 4 5 1 2 3 6 7 8 2000Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started