------------!--------Please summarize the following text. Do not exceed 3 powerpoint slides.--------!-----------

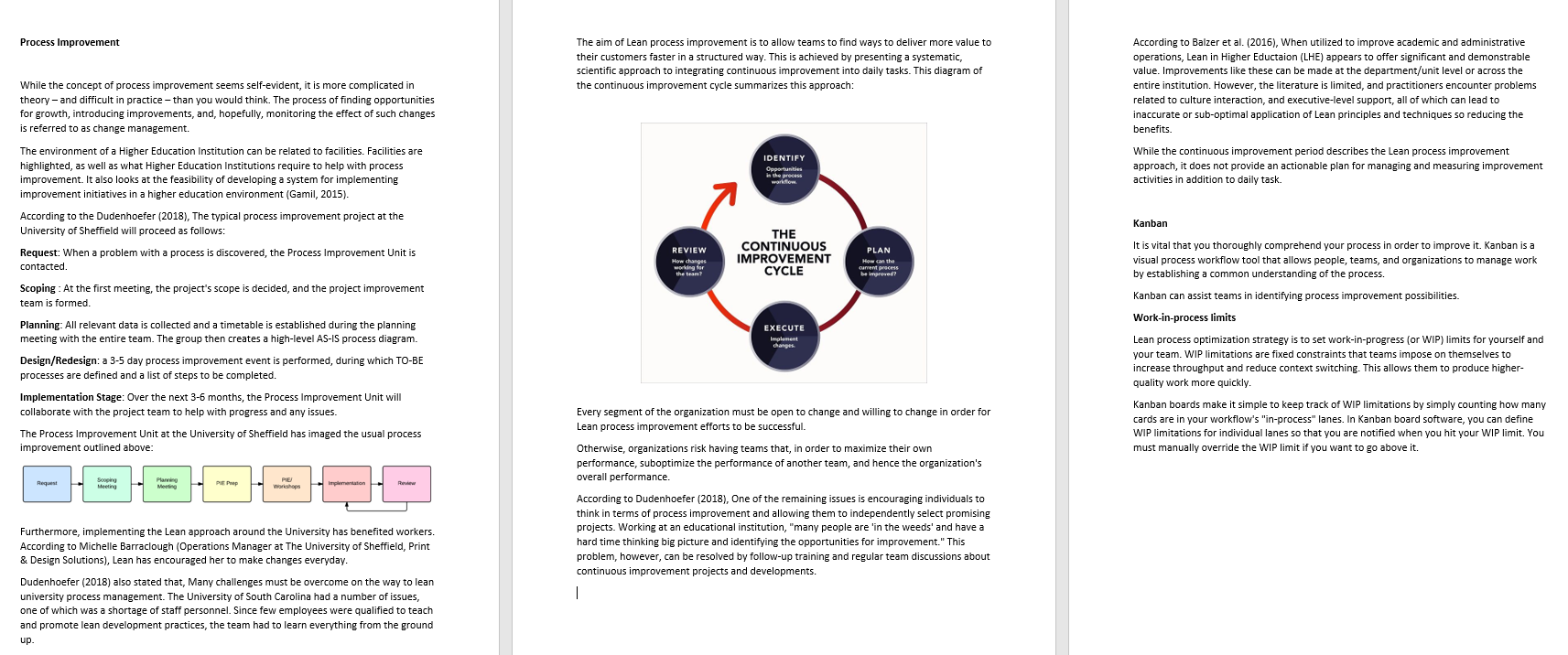

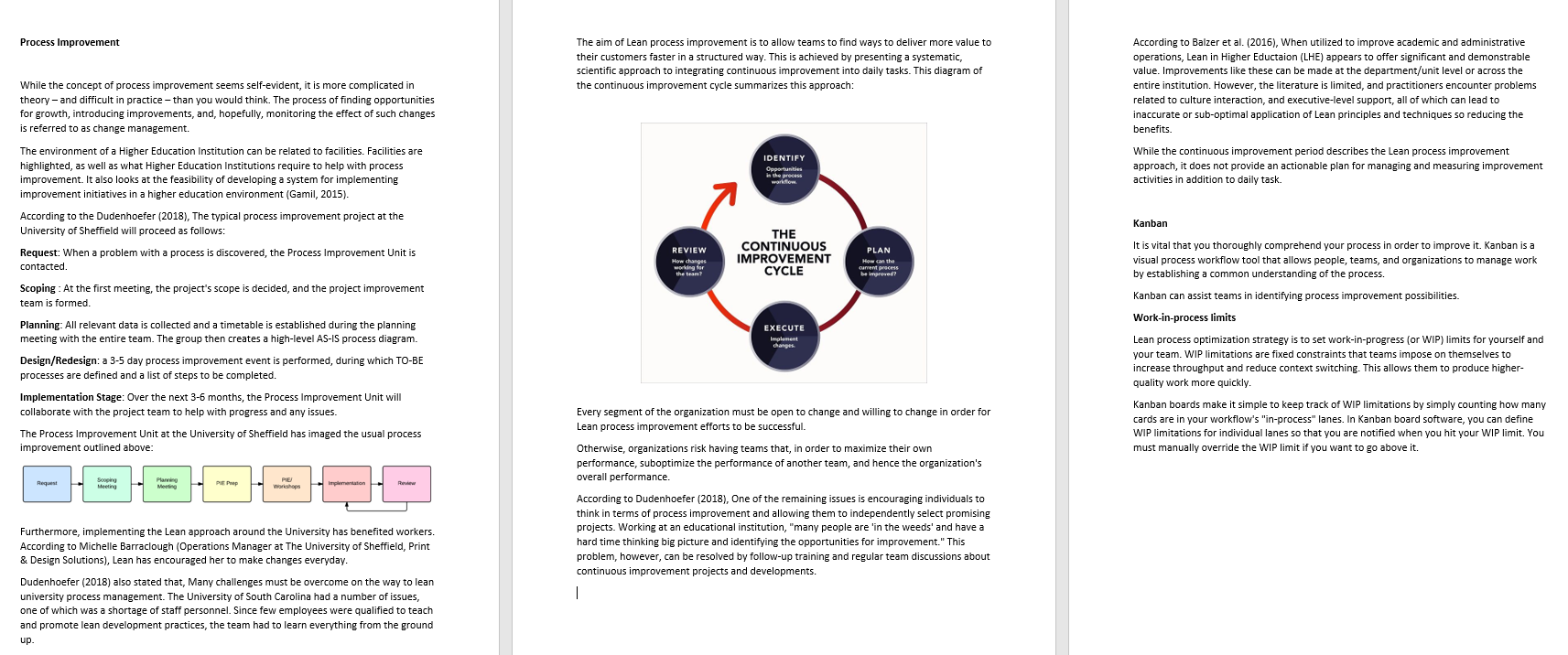

Process Improvement The aim of Lean process improvement is to allow teams to find ways to deliver more value to their customers faster in a structured way. This is achieved by presenting a systematic, scientific approach to integrating continuous improvement into daily tasks. This diagram of the continuous improvement cycle summarizes this approach: According to Balzer et al. (2016), When utilized to improve academic and administrative operations, Lean in Higher Eductaion (LHE) appears to offer significant and demonstrable value. Improvements like these can be made at the department/unit level or across the entire institution. However, the literature is limited, and practitioners encounter problems related to culture interaction, and executive-level support, all of which can lead to inaccurate or sub-optimal application of Lean principles and techniques so reducing the benefits. While the concept of process improvement seems self-evident, it is more complicated in theory - and difficult in practice - than you would think. The process of finding opportunities for growth, introducing improvements, and, hopefully, monitoring the effect of such changes is referred to as change management. The environment of a Higher Education Institution can be related to facilities. Facilities are highlighted, as well as what Higher Education Institutions require to help with process improvement. It also looks at the feasibility of developing a system for implementing improvement initiatives in a higher education environment (Gamil, 2015). IDENTIFY Opportunities in the process workflow While the continuous improvement period describes the Lean process improvement approach, it does not provide an actionable plan for managing and measuring improvement activities in addition to daily task. the According to the Dudenhoefer (2018), The typical process improvement project University of Sheffield will proceed as follows: Kanban PLAN Request: When a problem with a process is discovered, the Process Improvement Unit is contacted. Scoping : At the first meeting, the project's scope is decided, and the project improvement , , team is formed THE CONTINUOUS IMPROVEMENT CYCLE REVIEW How changes working for the team? How can the current process beroved It is vital that you thoroughly comprehend your process in order to improve it. Kanban is a visual process workflow tool that allows people, teams, and organizations to manage work by establishing a common understanding of the process. Kanban can assist teams in identifying process improvement possibilities. Work-in-process limits Lean process optimization strategy is to set work-in-progress (or WIP) limits for yourself and your team. WIP limitations are fixed constraints that teams impose on themselves to increase throughput and reduce context switching. This allows them to produce higher- quality work more quickly. EXECUTE Implement dhanges Planning: All relevant data is collected and a timetable is established during the planning meeting with the entire team. The group then creates a high-level AS-IS process diagram. Design/Redesign: a 3-5 day process improvement event is performed, during which TO-BE processes are defined and a list of steps to be completed. Implementation Stage: Over the next 3-6 months, the Process Improvement Unit will collaborate with the project team to help with progress and any issues. The Process Improvement Unit at the University of Sheffield has imaged the usual process improvement outlined above: Every segment of the organization must be open to change and willing to change in order for Lean process improvement efforts to be successful. Kanban boards make it simple to keep track of WIP limitations by simply counting how many cards are in your workflow's "in-process" lanes. In Kanban board software, you can define WIP limitations for individual lanes so that you are notified when you hit your WIP limit. You must manually override the WIP limit if you want to go above it. Request PIE Scopine Meeting Planning Meeting PE Prep lementation Review Otherwise, organizations risk having teams that, in order to maximize their own performance, suboptimize the performance of another team, and hence the organization's overall performance. According to Dudenhoefer (2018), One of the remaining issues is encouraging individuals to think in terms of process improvement and allowing them to independently select promising projects. Working at an educational institution, "many people are in the weeds' and have a hard time thinking big picture and identifying the opportunities for improvement." This problem, however, can be resolved by follow-up training and regular team discussions about continuous improvement projects and developments. | Furthermore, implementing the Lean approach around the University has benefited workers. According to Michelle Barraclough (Operations Manager at The University of Sheffield, Print & Design Solutions), Lean has encouraged her to make changes everyday. Dudenhoefer (2018) also stated that, Many challenges must be overcome on the way to lean university process management. The University of South Carolina had a number of issues, one of which was a shortage of staff personnel. Since few employees were qualified to teach and promote lean development practices, the team had to learn everything from the ground up. Process Improvement The aim of Lean process improvement is to allow teams to find ways to deliver more value to their customers faster in a structured way. This is achieved by presenting a systematic, scientific approach to integrating continuous improvement into daily tasks. This diagram of the continuous improvement cycle summarizes this approach: According to Balzer et al. (2016), When utilized to improve academic and administrative operations, Lean in Higher Eductaion (LHE) appears to offer significant and demonstrable value. Improvements like these can be made at the department/unit level or across the entire institution. However, the literature is limited, and practitioners encounter problems related to culture interaction, and executive-level support, all of which can lead to inaccurate or sub-optimal application of Lean principles and techniques so reducing the benefits. While the concept of process improvement seems self-evident, it is more complicated in theory - and difficult in practice - than you would think. The process of finding opportunities for growth, introducing improvements, and, hopefully, monitoring the effect of such changes is referred to as change management. The environment of a Higher Education Institution can be related to facilities. Facilities are highlighted, as well as what Higher Education Institutions require to help with process improvement. It also looks at the feasibility of developing a system for implementing improvement initiatives in a higher education environment (Gamil, 2015). IDENTIFY Opportunities in the process workflow While the continuous improvement period describes the Lean process improvement approach, it does not provide an actionable plan for managing and measuring improvement activities in addition to daily task. the According to the Dudenhoefer (2018), The typical process improvement project University of Sheffield will proceed as follows: Kanban PLAN Request: When a problem with a process is discovered, the Process Improvement Unit is contacted. Scoping : At the first meeting, the project's scope is decided, and the project improvement , , team is formed THE CONTINUOUS IMPROVEMENT CYCLE REVIEW How changes working for the team? How can the current process beroved It is vital that you thoroughly comprehend your process in order to improve it. Kanban is a visual process workflow tool that allows people, teams, and organizations to manage work by establishing a common understanding of the process. Kanban can assist teams in identifying process improvement possibilities. Work-in-process limits Lean process optimization strategy is to set work-in-progress (or WIP) limits for yourself and your team. WIP limitations are fixed constraints that teams impose on themselves to increase throughput and reduce context switching. This allows them to produce higher- quality work more quickly. EXECUTE Implement dhanges Planning: All relevant data is collected and a timetable is established during the planning meeting with the entire team. The group then creates a high-level AS-IS process diagram. Design/Redesign: a 3-5 day process improvement event is performed, during which TO-BE processes are defined and a list of steps to be completed. Implementation Stage: Over the next 3-6 months, the Process Improvement Unit will collaborate with the project team to help with progress and any issues. The Process Improvement Unit at the University of Sheffield has imaged the usual process improvement outlined above: Every segment of the organization must be open to change and willing to change in order for Lean process improvement efforts to be successful. Kanban boards make it simple to keep track of WIP limitations by simply counting how many cards are in your workflow's "in-process" lanes. In Kanban board software, you can define WIP limitations for individual lanes so that you are notified when you hit your WIP limit. You must manually override the WIP limit if you want to go above it. Request PIE Scopine Meeting Planning Meeting PE Prep lementation Review Otherwise, organizations risk having teams that, in order to maximize their own performance, suboptimize the performance of another team, and hence the organization's overall performance. According to Dudenhoefer (2018), One of the remaining issues is encouraging individuals to think in terms of process improvement and allowing them to independently select promising projects. Working at an educational institution, "many people are in the weeds' and have a hard time thinking big picture and identifying the opportunities for improvement." This problem, however, can be resolved by follow-up training and regular team discussions about continuous improvement projects and developments. | Furthermore, implementing the Lean approach around the University has benefited workers. According to Michelle Barraclough (Operations Manager at The University of Sheffield, Print & Design Solutions), Lean has encouraged her to make changes everyday. Dudenhoefer (2018) also stated that, Many challenges must be overcome on the way to lean university process management. The University of South Carolina had a number of issues, one of which was a shortage of staff personnel. Since few employees were qualified to teach and promote lean development practices, the team had to learn everything from the ground up