Question: Please write up the below case study addressing questions with an executive summary( total not more than 3 pages) -How appropriate is a State-Gate method

Please write up the below case study addressing questions with an executive summary( total not more than 3 pages)

-How appropriate is a State-Gate method for this type of early-stage firm project? -CAD efficiency was the largest project cost. What steps would you have taken to reduce these costs? The last 10% of the project took much longer than expected - due to unforeseen technical issues in the design and lag time with China. Please list some steps that might improve the efficiency of these iterations. How could additional project management help? -Could new tools such as project wikis (see PBWiki.com) help? How? -Would you view this project as an incremental innovation or a radical innovation? why?

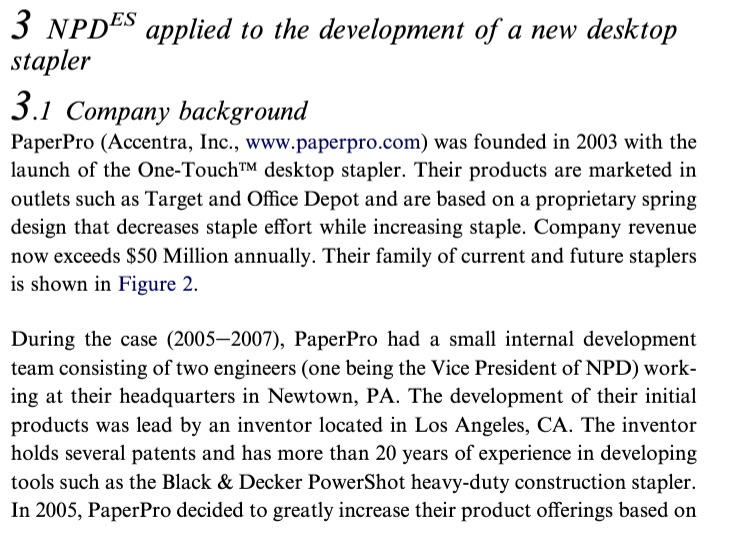

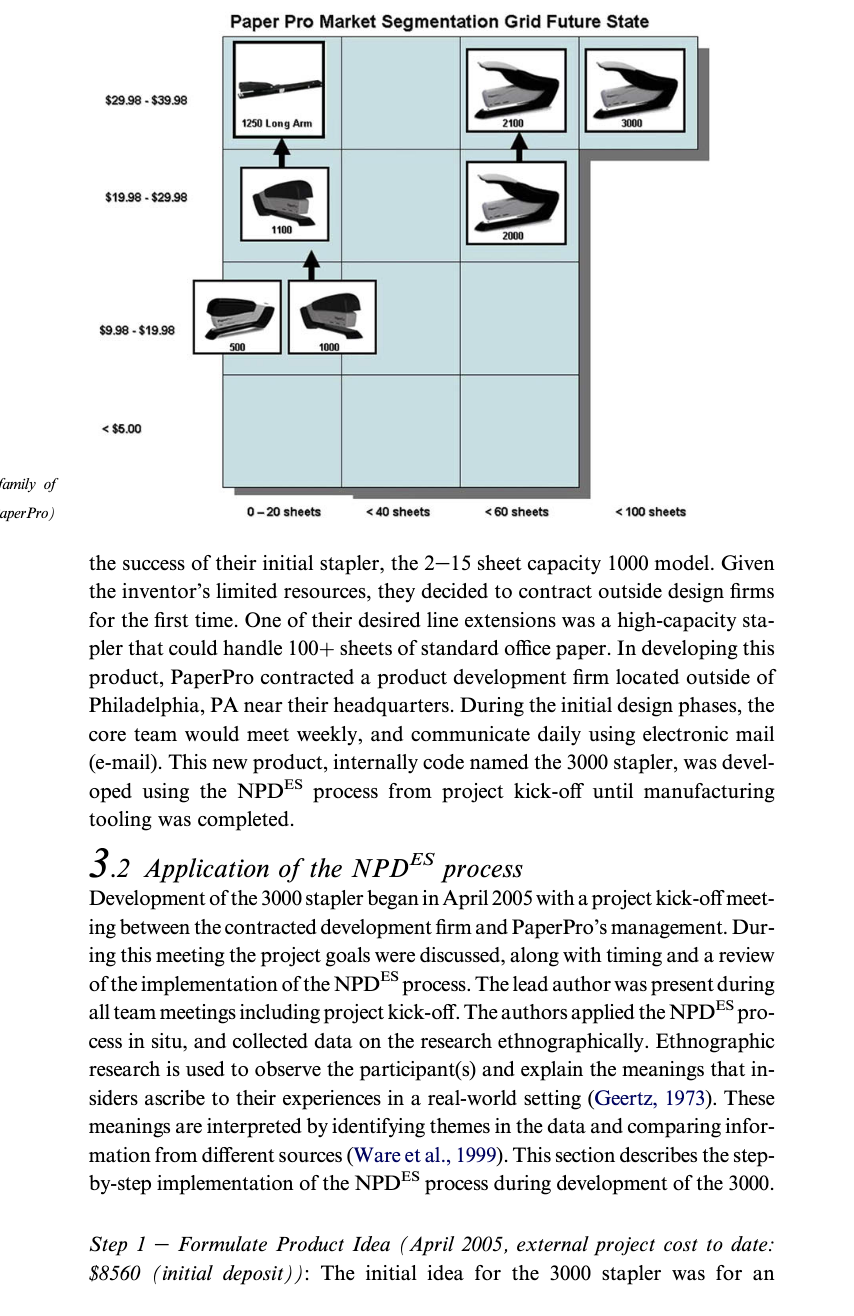

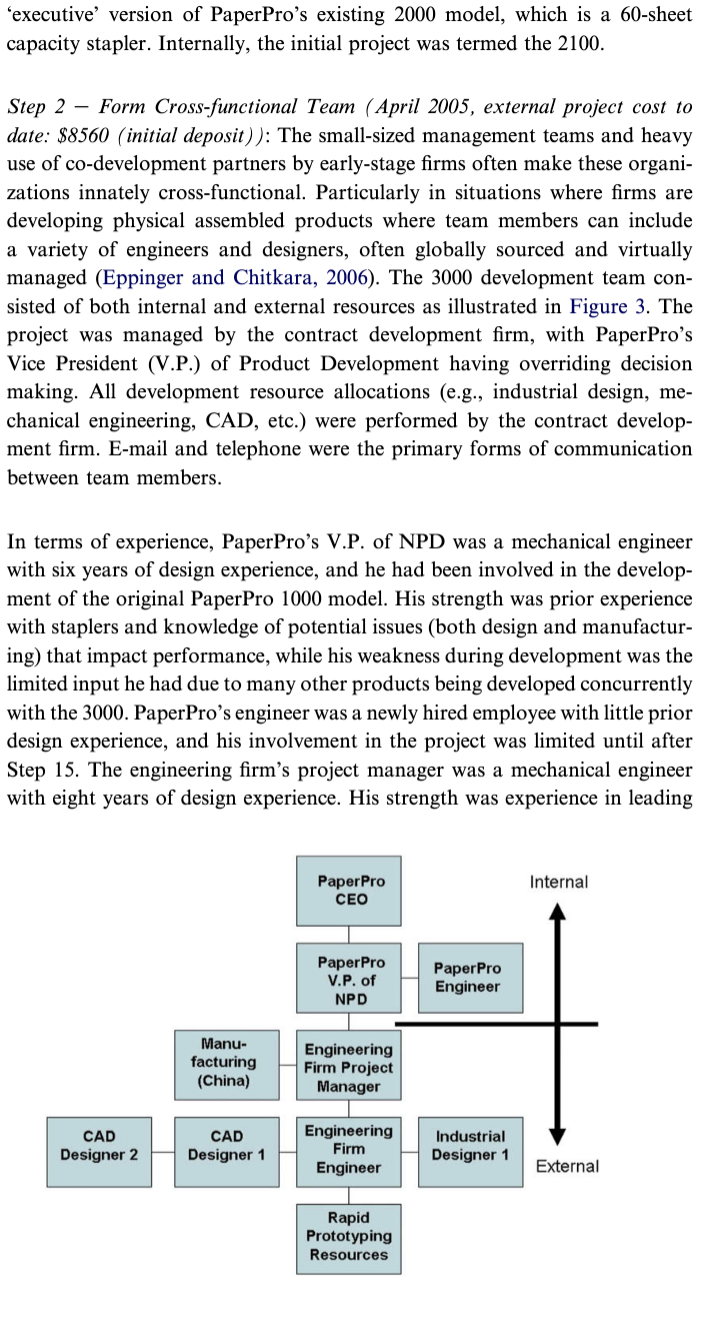

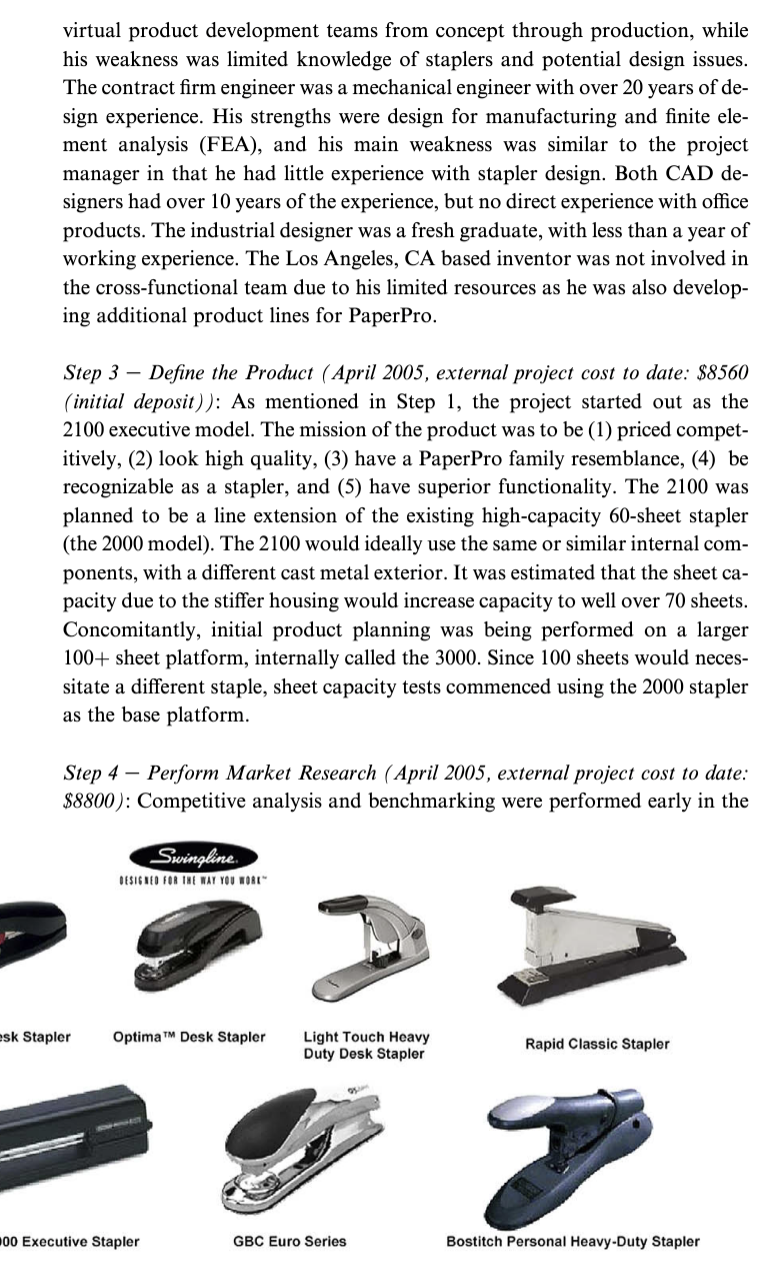

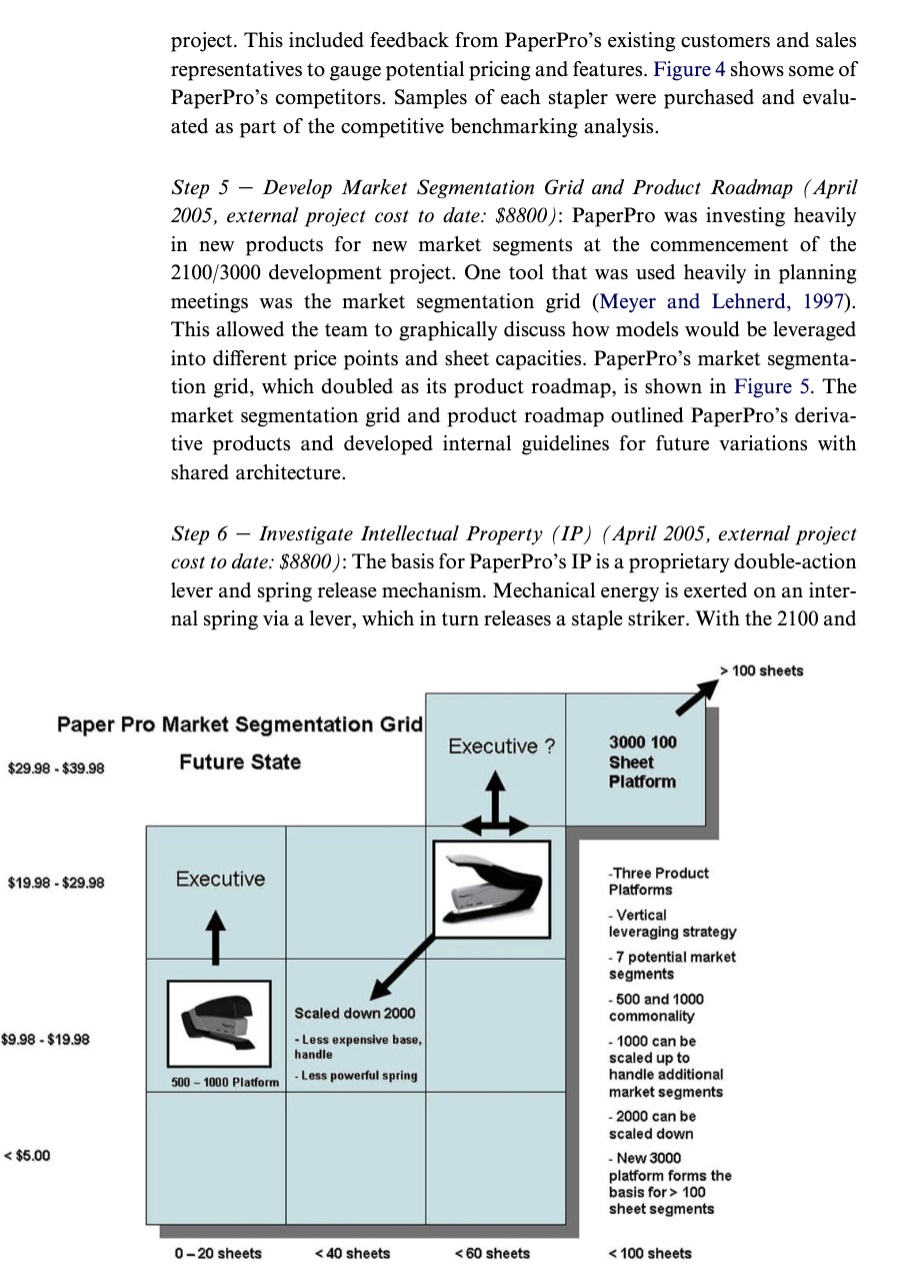

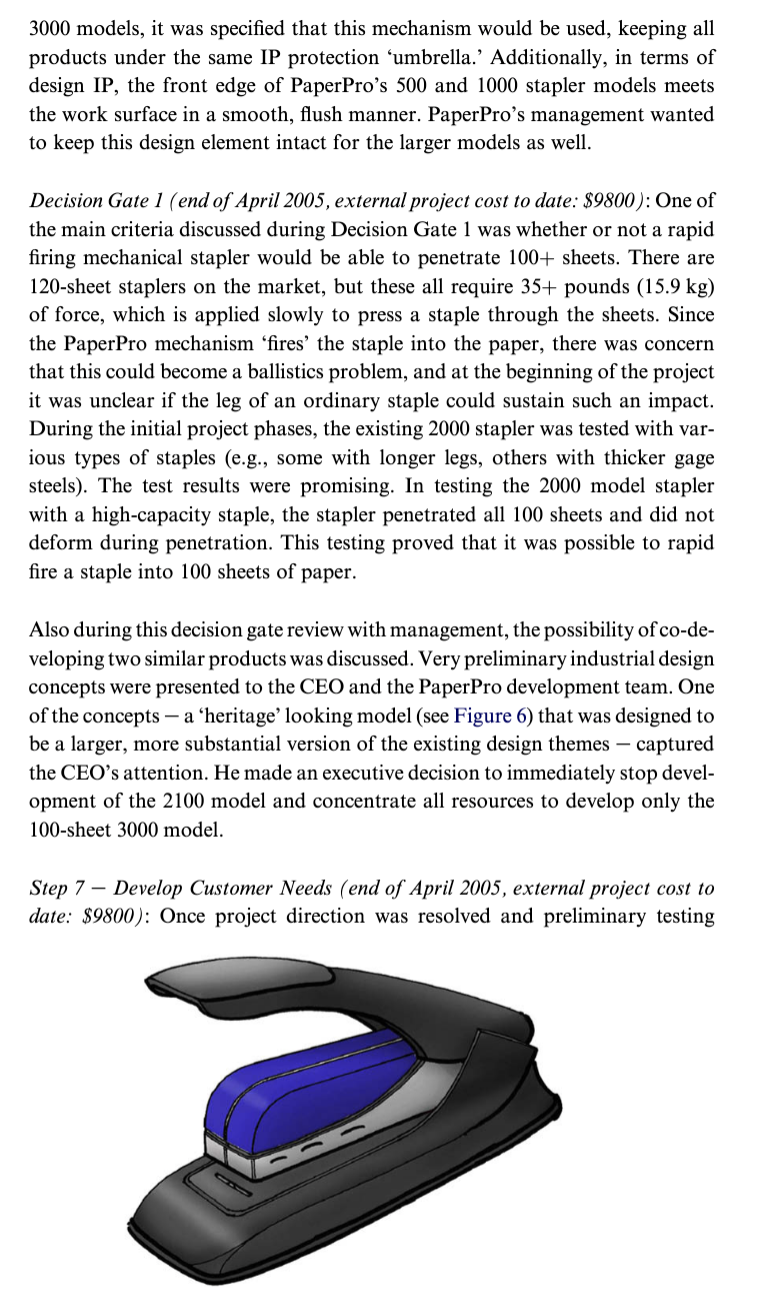

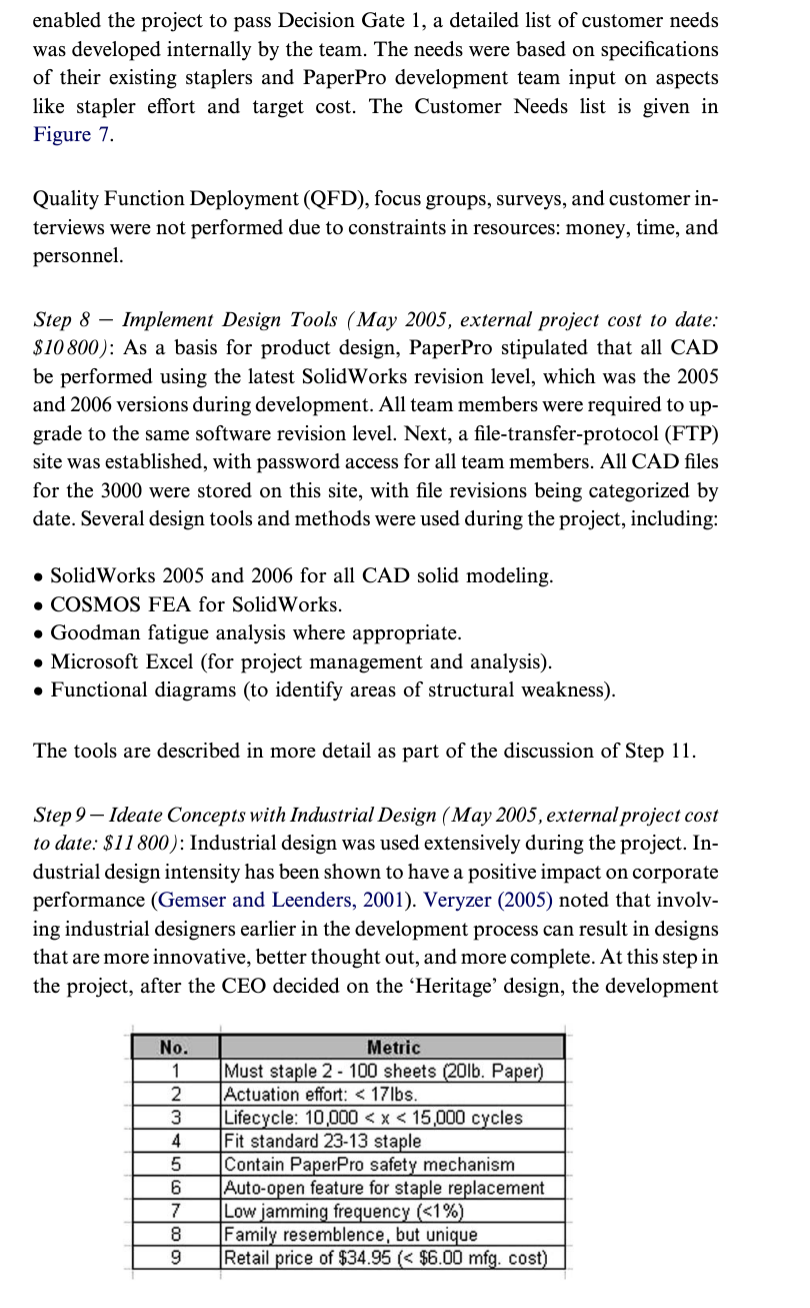

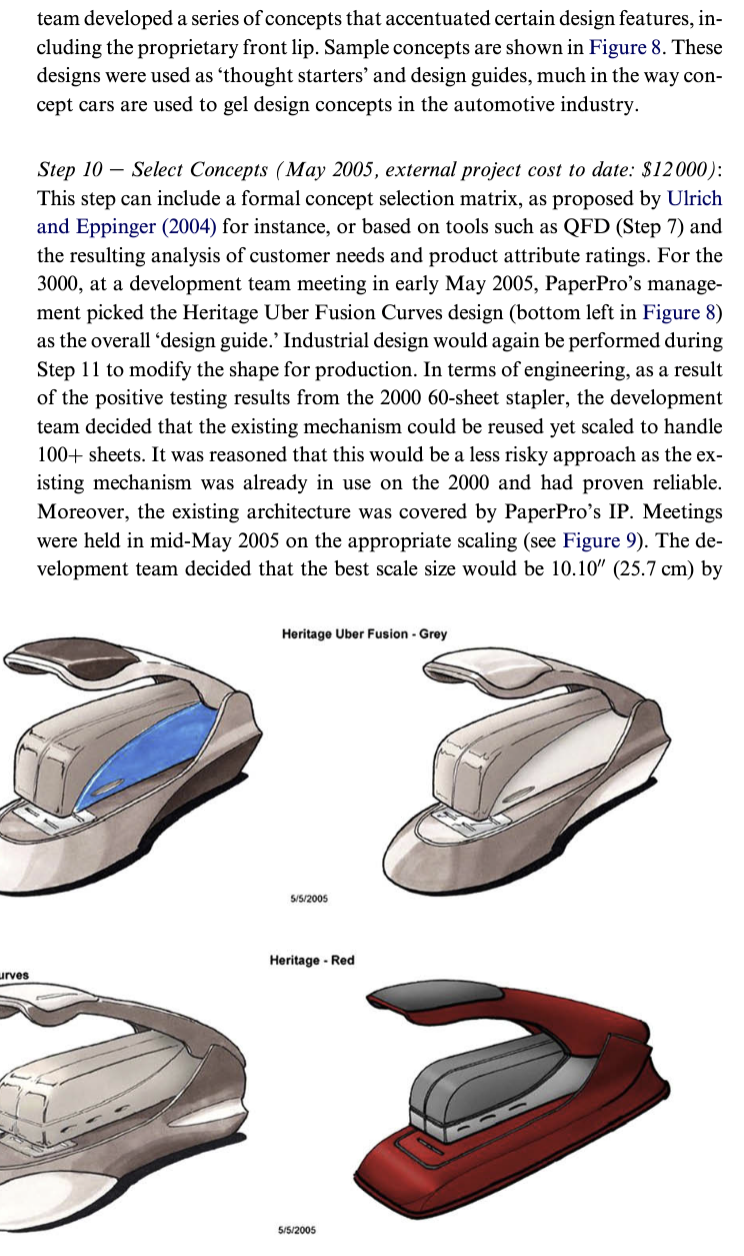

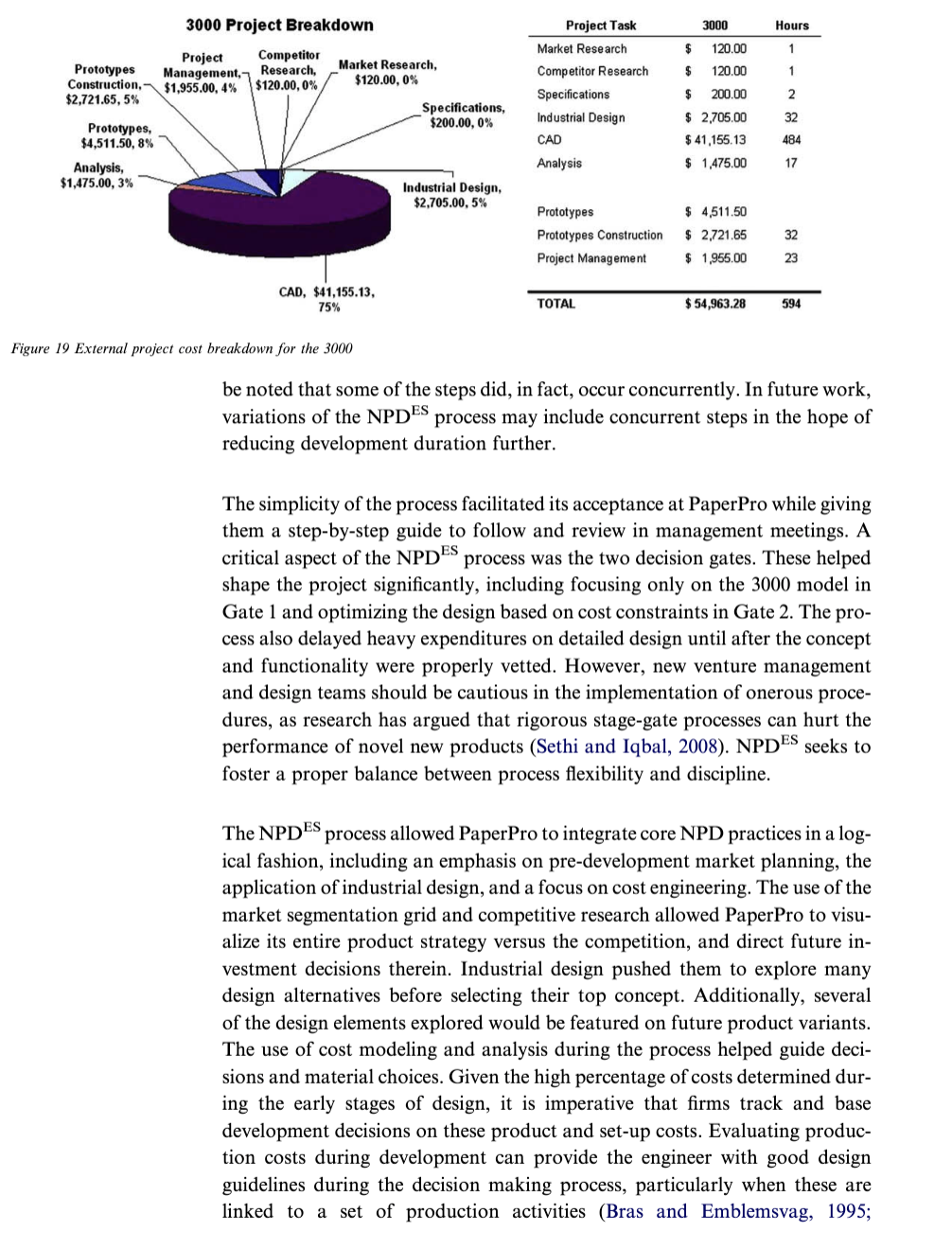

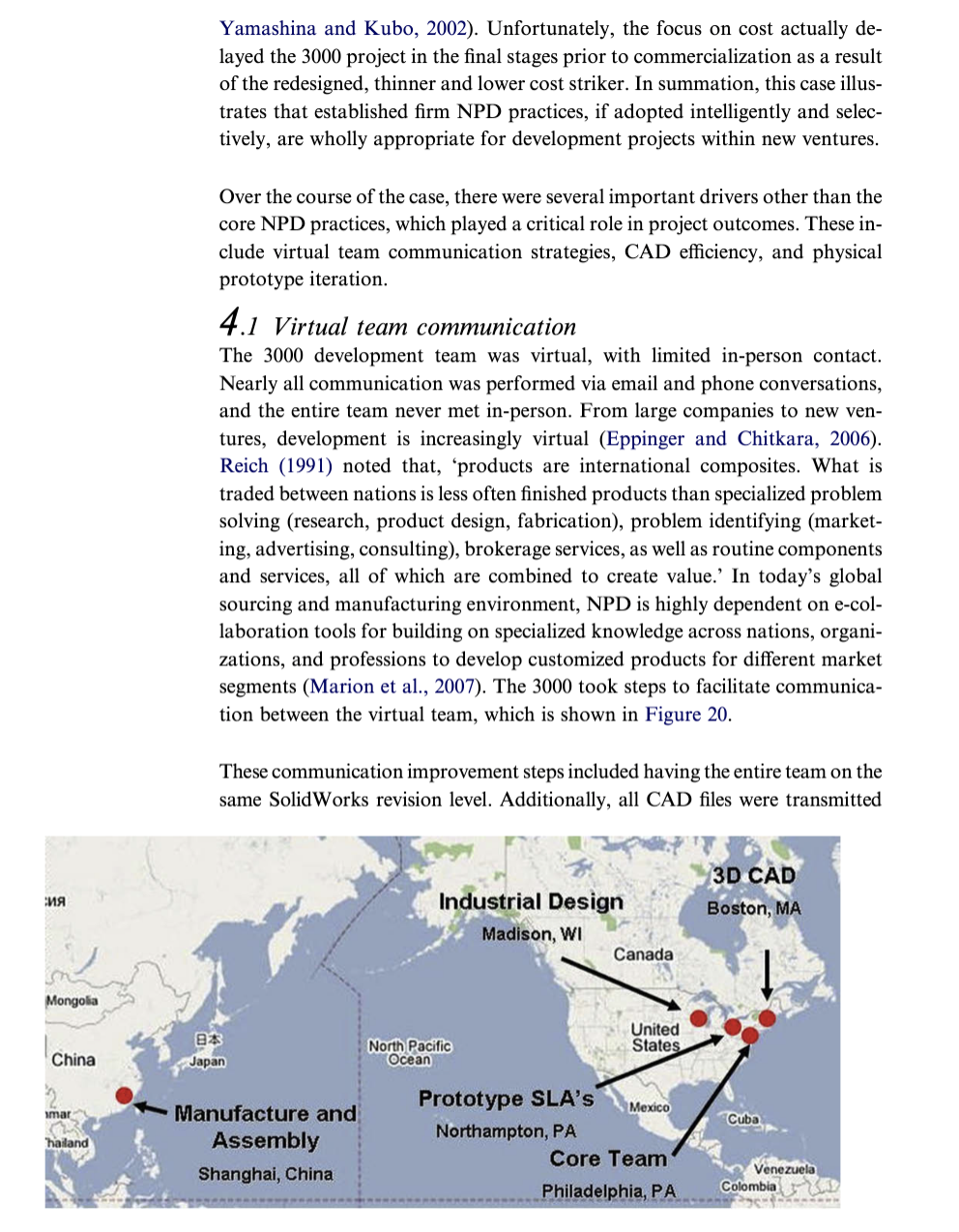

3NPDES applied to the development of a new desktop stapler 3.1 Company background PaperPro (Accentra, Inc., www.paperpro.com) was founded in 2003 with the launch of the One-Touch TM desktop stapler. Their products are marketed in outlets such as Target and Office Depot and are based on a proprietary spring design that decreases staple effort while increasing staple. Company revenue now exceeds $50 Million annually. Their family of current and future staplers is shown in Figure 2. During the case (2005-2007), PaperPro had a small internal development team consisting of two engineers (one being the Vice President of NPD) working at their headquarters in Newtown, PA. The development of their initial products was lead by an inventor located in Los Angeles, CA. The inventor holds several patents and has more than 20 years of experience in developing tools such as the Black \& Decker PowerShot heavy-duty construction stapler. In 2005, PaperPro decided to greatly increase their product offerings based on Danar Dra Markat Sarimantation Carid Ftra Stata the success of their initial stapler, the 2-15 sheet capacity 1000 model. Given the inventor's limited resources, they decided to contract outside design firms for the first time. One of their desired line extensions was a high-capacity stapler that could handle 100+ sheets of standard office paper. In developing this product, PaperPro contracted a product development firm located outside of Philadelphia, PA near their headquarters. During the initial design phases, the core team would meet weekly, and communicate daily using electronic mail (e-mail). This new product, internally code named the 3000 stapler, was developed using the NPDES process from project kick-off until manufacturing tooling was completed. 3.2 Application of the NPDES process Development of the 3000 stapler began in April 2005 with a project kick-off meeting between the contracted development firm and PaperPro's management. During this meeting the project goals were discussed, along with timing and a review of the implementation of the NPDES process. The lead author was present during all team meetings including project kick-off. The authors applied the NPD ES process in situ, and collected data on the research ethnographically. Ethnographic research is used to observe the participant(s) and explain the meanings that insiders ascribe to their experiences in a real-world setting (Geertz, 1973). These meanings are interpreted by identifying themes in the data and comparing information from different sources (Ware et al., 1999). This section describes the stepby-step implementation of the NPDES process during development of the 3000 . Step 1 - Formulate Product Idea (April 2005, external project cost to date: capacity stapler. Internally, the initial project was termed the 2100 . Step 2 - Form Cross-functional Team (April 2005, external project cost to date: $8560 (initial deposit)): The small-sized management teams and heavy use of co-development partners by early-stage firms often make these organizations innately cross-functional. Particularly in situations where firms are developing physical assembled products where team members can include a variety of engineers and designers, often globally sourced and virtually managed (Eppinger and Chitkara, 2006). The 3000 development team consisted of both internal and external resources as illustrated in Figure 3. The project was managed by the contract development firm, with PaperPro's Vice President (V.P.) of Product Development having overriding decision making. All development resource allocations (e.g., industrial design, mechanical engineering, CAD, etc.) were performed by the contract development firm. E-mail and telephone were the primary forms of communication between team members. In terms of experience, PaperPro's V.P. of NPD was a mechanical engineer with six years of design experience, and he had been involved in the development of the original PaperPro 1000 model. His strength was prior experience with staplers and knowledge of potential issues (both design and manufacturing) that impact performance, while his weakness during development was the limited input he had due to many other products being developed concurrently with the 3000. PaperPro's engineer was a newly hired employee with little prior design experience, and his involvement in the project was limited until after Step 15. The engineering firm's project manager was a mechanical engineer with eight years of design experience. His strength was experience in leading virtual product development teams from concept through production, while his weakness was limited knowledge of staplers and potential design issues. The contract firm engineer was a mechanical engineer with over 20 years of design experience. His strengths were design for manufacturing and finite element analysis (FEA), and his main weakness was similar to the project manager in that he had little experience with stapler design. Both CAD designers had over 10 years of the experience, but no direct experience with office products. The industrial designer was a fresh graduate, with less than a year of working experience. The Los Angeles, CA based inventor was not involved in the cross-functional team due to his limited resources as he was also developing additional product lines for PaperPro. Step 3 Define the Product (April 2005, external project cost to date: $8560 (initial deposit)): As mentioned in Step 1, the project started out as the 2100 executive model. The mission of the product was to be (1) priced competitively, (2) look high quality, (3) have a PaperPro family resemblance, (4) be recognizable as a stapler, and (5) have superior functionality. The 2100 was planned to be a line extension of the existing high-capacity 60 -sheet stapler (the 2000 model). The 2100 would ideally use the same or similar internal components, with a different cast metal exterior. It was estimated that the sheet capacity due to the stiffer housing would increase capacity to well over 70 sheets. Concomitantly, initial product planning was being performed on a larger 100+ sheet platform, internally called the 3000 . Since 100 sheets would necessitate a different staple, sheet capacity tests commenced using the 2000 stapler as the base platform. Step 4 - Perform Market Research (April 2005, external project cost to date: $8800) : Competitive analysis and benchmarking were performed early in the project. This included feedback from PaperPro's existing customers and sales representatives to gauge potential pricing and features. Figure 4 shows some of PaperPro's competitors. Samples of each stapler were purchased and evaluated as part of the competitive benchmarking analysis. Step 5 - Develop Market Segmentation Grid and Product Roadmap (April 2005 , external project cost to date: $8800 ): PaperPro was investing heavily in new products for new market segments at the commencement of the 2100/3000 development project. One tool that was used heavily in planning meetings was the market segmentation grid (Meyer and Lehnerd, 1997). This allowed the team to graphically discuss how models would be leveraged into different price points and sheet capacities. PaperPro's market segmentation grid, which doubled as its product roadmap, is shown in Figure 5. The market segmentation grid and product roadmap outlined PaperPro's derivative products and developed internal guidelines for future variations with shared architecture. Step 6 - Investigate Intellectual Property (IP) (April 2005, external project cost to date: $8800) : The basis for PaperPro's IP is a proprietary double-action lever and spring release mechanism. Mechanical energy is exerted on an internal spring via a lever, which in turn releases a staple striker. With the 2100 and 3000 models, it was specified that this mechanism would be used, keeping all products under the same IP protection 'umbrella.' Additionally, in terms of design IP, the front edge of PaperPro's 500 and 1000 stapler models meets the work surface in a smooth, flush manner. PaperPro's management wanted to keep this design element intact for the larger models as well. Decision Gate 1 ( end of April 2005, external project cost to date: \$9800): One of the main criteria discussed during Decision Gate 1 was whether or not a rapid firing mechanical stapler would be able to penetrate 100+ sheets. There are 120-sheet staplers on the market, but these all require 35+ pounds (15.9kg) of force, which is applied slowly to press a staple through the sheets. Since the PaperPro mechanism 'fires' the staple into the paper, there was concern that this could become a ballistics problem, and at the beginning of the project it was unclear if the leg of an ordinary staple could sustain such an impact. During the initial project phases, the existing 2000 stapler was tested with various types of staples (e.g., some with longer legs, others with thicker gage steels). The test results were promising. In testing the 2000 model stapler with a high-capacity staple, the stapler penetrated all 100 sheets and did not deform during penetration. This testing proved that it was possible to rapid fire a staple into 100 sheets of paper. Also during this decision gate review with management, the possibility of co-developing two similar products was discussed. Very preliminary industrial design concepts were presented to the CEO and the PaperPro development team. One of the concepts - a 'heritage' looking model (see Figure 6) that was designed to be a larger, more substantial version of the existing design themes - captured the CEO's attention. He made an executive decision to immediately stop development of the 2100 model and concentrate all resources to develop only the 100-sheet 3000 model. Step 7 - Develop Customer Needs (end of April 2005, external project cost to date: $9800 ): Once project direction was resolved and preliminary testing enabled the project to pass Decision Gate 1, a detailed list of customer needs was developed internally by the team. The needs were based on specifications of their existing staplers and PaperPro development team input on aspects like stapler effort and target cost. The Customer Needs list is given in Figure 7. Quality Function Deployment (QFD), focus groups, surveys, and customer interviews were not performed due to constraints in resources: money, time, and personnel. Step 8 - Implement Design Tools (May 2005, external project cost to date: \$10800): As a basis for product design, PaperPro stipulated that all CAD be performed using the latest SolidWorks revision level, which was the 2005 and 2006 versions during development. All team members were required to upgrade to the same software revision level. Next, a file-transfer-protocol (FTP) site was established, with password access for all team members. All CAD files for the 3000 were stored on this site, with file revisions being categorized by date. Several design tools and methods were used during the project, including: - SolidWorks 2005 and 2006 for all CAD solid modeling. - COSMOS FEA for SolidWorks. - Goodman fatigue analysis where appropriate. - Microsoft Excel (for project management and analysis). - Functional diagrams (to identify areas of structural weakness). The tools are described in more detail as part of the discussion of Step 11. Step 9 - Ideate Concepts with Industrial Design (May 2005, external project cost to date: $11800 ): Industrial design was used extensively during the project. Industrial design intensity has been shown to have a positive impact on corporate performance (Gemser and Leenders, 2001). Veryzer (2005) noted that involving industrial designers earlier in the development process can result in designs that are more innovative, better thought out, and more complete. At this step in the project, after the CEO decided on the 'Heritage' design, the development team developed a series of concepts that accentuated certain design features, including the proprietary front lip. Sample concepts are shown in Figure 8. These designs were used as 'thought starters' and design guides, much in the way concept cars are used to gel design concepts in the automotive industry. Step 10 - Select Concepts (May 2005, external project cost to date: $12000 ): This step can include a formal concept selection matrix, as proposed by Ulrich and Eppinger (2004) for instance, or based on tools such as QFD (Step 7) and the resulting analysis of customer needs and product attribute ratings. For the 3000 , at a development team meeting in early May 2005, PaperPro's management picked the Heritage Uber Fusion Curves design (bottom left in Figure 8) as the overall 'design guide.' Industrial design would again be performed during Step 11 to modify the shape for production. In terms of engineering, as a result of the positive testing results from the 2000 60-sheet stapler, the development team decided that the existing mechanism could be reused yet scaled to handle 100+ sheets. It was reasoned that this would be a less risky approach as the existing mechanism was already in use on the 2000 and had proven reliable. Moreover, the existing architecture was covered by PaperPro's IP. Meetings were held in mid-May 2005 on the appropriate scaling (see Figure 9). The development team decided that the best scale size would be 10.10(25.7cm) by Figure 9 Scaling the 2000 to create the 3000 stapler 5.87(14.9cm ) (the second expanded silhouette) in Figure 9 - the existing 2000 is the smallest silhouette (8.60(21.8cm) by 5.00(12.7cm)). Step 11 - Initiate Detailed Product Design (May through July 2005, external project cost to date: $32000 ): Product design began in earnest at the end of May 2005. As a starting point, the new 3000 model was based on the existing 2000 CAD models, and all components (e.g., base, handle, and housing) were scaled to the agreed upon dimensions. Critical to the function of the stapler is the main power spring, which is a pre-loaded leaf spring that undergoes deformation via a handle-actuated lever. At its maximum rise, the lever releases the main power spring, which drives a striker into the staple and through the paper. The main power spring is shown in Figure 10 as the curved (red) horizontal line. The other major components - lever, handle, main power spring, and striker - are shown in Figure 11. A first step in scaling the 2000 was to quantify the output force of the main power spring. As a control, the power spring in the 2000 was analyzed using COSMOS finite element analysis (FEA). The CAD model of the spring was ure 113000 section denoting major components then thickened to gauge the impact on the FEA output force result. Concurrently, the force required to staple 100 sheets of paper was investigated using existing staplers and results from FEA, with the hope of being able to quantify the amount of spring force needed. A spring force curve was then developed, which is shown in Figure 12. Based on this graph and the FEA testing, an initial series of spring shapes and thicknesses were designed. The lever and striker were investigated next for their robustness and scaled appropriately. This included lengthening and strengthening the lever and adding material to the striker. The revised 3000 CAD model was completed in July 2005. A comparison between the 2000 and 3000 designs is shown in Figure 13. After the initial design and analysis were completed, a design review was held in early August, and prototypes were subsequently manufactured in China. These included stereolithography (SLA) parts and stamped components made exactly to CAD specifications. It took approximately four weeks to receive the prototypes, and testing commenced in September 2005 on the initial prototypes. The initial prototype housing was a clear plastic SLA (in order to see the mechanism in action and verify component geometry). As expected, the SLA housings began to fail after several firings due to the high internal forces. However, at this time 80+ sheets were stapled, verifying the use of a new heavy-duty staple, the 23-13 (longer staple legs for 100 sheets and a thicker wire gage). After a day of testing, the design team decided to begin CNC machining a bronze housing to simulate the structure of the production unit, as it would utilize a cast zinc housing. The CNC-machined housing was received two weeks later in October 2005. Unfortunately, the unit was not dimensionally correct and had to be machined again locally. In mid-November, testing began on the improved bronze housing model. Testing on the bronze model proved very fruitful: 82 sheets were successfully stapled and crimped; however, the prototype uncovered several design flaws. The first was the striker, which failed from shear after only 45 cycles. Moreover, the handle effort was high, and the stapler had a large amount of recoil. An Excel-based list was started and maintained to track issues and their resolution. At this point in the process, an Energy-Material-Signal (EMS) diagram was developed to help identify potential design issues. A function diagram (Pahl and Beitz, 1996) or EMS model (Ogot, 2005) is a 'black box' model of the system where the system inputs and outputs are determined. Then each flow is traced through the system to map out the internal functions or sub-functions of the product (Steva et al., 2006). The 3000 EMS diagram and resulting issues (zigzag lines) are shown in Figure 14. These include striker fatigue strength and handle effort. The EMS diagram was used throughout the process to show visual interaction of different components and potential detrimental (or positive) impact. A Goodman fatigue analysis was performed to determine that the striker was insufficient to handle the required stresses. A full team project meeting was held in November to review the testing and next steps, which included: (1) redesigning the striker thickness to be double that of the existing version (the Goodman analysis showed this to be well within the expected lifecycle range), (2) increase the main power spring force by 10%, (3) study and modify the handle and lever to reduce effort, (4) have a rapid prototype casting made to make the 3rd round of testing as close to production reality as possible, and (5) make final industrial design changes to capture the initial Heritage Uber Fusion Curves concept. After completing the analyses, the CAD model was modified to reflect the design changes. The rapid prototypes were completed in January 2006. As with the bronze housing, the zinc-casting prototype had to be post-machined locally to meet specifications. Testing on the 3rd round was completed by the end of January 2006, and subsequent revisions based on this testing are detailed in Figure 15. The improved double thick striker did not fail, and 93 sheets were successfully stapled. The handle force was now at 17 pounds (7.7kg). Based on prototype testing and review of the CAD models by the PaperPro development team, it was decided to clean up any additional issues with the design and finalize it for the hand-off for tooling construction. A final, 4th machined housing was constructed in China for testing during tooling construction. Step 12 - Perform Cost Modeling (September 2005, external project cost to date: $42000 ): Research has shown that 70% of ultimate product cost is determined during the early stages of design (Duverlie and Castelain, 1999). Several evaluation tools can be used in this step, including piece price estimates, margin analysis, and commonality indices to aid in design and ultimate sourcing decisions (Marion et al., 2007). Cost modeling was used extensively during development of the 3000 . This included manufacturer cost estimates for each component quoted at each prototype revision. In addition, parts were often quoted to vendors outside of the current supply chain for comparison. In June 2006, PaperPro changed the striker design to be slightly thinner due to high cost. A Goodman analysis found that it should be acceptable, but the external design team recommended continuing with the original double thickness design, based on testing and analyses from January 2006. Decision Gate 2 (March 2006, external project cost to date: $48000 ): In early March 2006, a management review was held before initiating tooling for the 3000. The team felt that additional time and cost developing and testing non-production level prototypes were not advancing the project and that rapid advancement would instead come by tweaking samples from production tooling. Hence, the project moved forward to Final Design and Launch. Step 13 - Define and Refine Product Specifications (May 2006, external project cost to date: $49000) : The functional specifications of the finished product were unchanged from the initial list of customer needs (see Figure 7). These targets remained constant and were a challenge throughout development, particularly the cycle life of the striker. For each individual part; material, finish, and color specifications were developed and input into the CAD model. In support of the CAD models and associated Bill-of-Material (BOM) information, PaperPro's manufacturer was given dimensioned drawings to be used as a guide during tooling construction and debugging. Step 14 - Finalize Design (May through June 2006, external project cost to date: $52000) : As a result of tooling samples, the design continued to be refined throughout the remainder of 2006. An example of feedback between manufacturing and design can be seen in Figure 16 as the space between the spring and the housing was fine-tuned. Step 15 - Initiate Tooling Development and Prepare for Launch (June 2006, project cost to date: $54000) : By early 2007, small tweaks were being made to the production tooling. An Excel-based issue list (including both design and manufacturing issues) was used to track manufacturing tooling issues by PaperPro's development team. Denoted in the issue list was a description of the issue, potential solution, and features that would be changed in the control SolidWorks file (CAD model). The main design issue at the time of tooling debugging was striker failure, which was failing at approximately 3000 cycles, well below specification. The contracted design team was asked for input to resolve the issue in January 2007 , and they recommended their original double thickness striker as originally designed before cost engineering (Step 12) necessitated a redesign. Some modifications were made to the design to improve stress concentrations that improved life to approximately 5000 cycles, and PaperPro management decided this was sufficient due to the lower projected usage of the 3000 model versus lower capacity staplers such as the 1000 . Lifecycle and jamming testing was performed extensively in the spring and summer of 2007 to verify function before launch. During this period, pre-production units were given to sales representatives in the U.S. and Europe. The 3000 , officially named the PaperPro StackMaster, reached production in the third quarter of 2007 and is now sold worldwide. A photo of a production unit is shown in Figure 17. The 3000 project took 14 months from inception until tooling was initiated. This included three rounds of prototype construction and testing. During this time, weekly project meetings were held to review program progress, either in-person or via telephone between team members. Daily design e-mails were exchanged, and design updates on the FTP site were reviewed daily. The total cost of development, including PaperPro's internal resources was approximately $125000. The cost of high-volume injection molded tooling was approximately $120000. A graph of project costs by month is shown in Figure 18 , highlighting the three major rounds of testing and design modification. Note that the spikes in project development costs are directly related to CAD engineering hours, which were the largest project cost. A breakdown of the outside engineering firm project costs is shown in Figure 19 (not including PaperPro's internal person-hours). As seen, CAD accounted for the majority of the person-hours on the project; the second largest expense was the creation of US-based prototypes. All Chinese prototypes were created by the manufacturer at no cost to PaperPro. 4 Discussion In this paper, we examined the application of a simplified NPD process for early-stage firms termed NPDES. The process consists of three phases, fifteen steps, and two decision gates. In order to simplify and tailor the process for new ventures, the number of gates was limited and emphasis was put on upfront planning, industrial design, concept development, and the use of design tools. The impetus for the design of this NPD process was simplicity and straightforwardness for easy application within the often chaotic start-up environment. As such, the layout of the NPDES intentionally does not include aspects of concurrent processes and spiral development; however, it should Figure 19 External project cost breakdown for the 3000 be noted that some of the steps did, in fact, occur concurrently. In future work, variations of the NPDES process may include concurrent steps in the hope of reducing development duration further. The simplicity of the process facilitated its acceptance at PaperPro while giving them a step-by-step guide to follow and review in management meetings. A critical aspect of the NPDES process was the two decision gates. These helped shape the project significantly, including focusing only on the 3000 model in Gate 1 and optimizing the design based on cost constraints in Gate 2. The process also delayed heavy expenditures on detailed design until after the concept and functionality were properly vetted. However, new venture management and design teams should be cautious in the implementation of onerous procedures, as research has argued that rigorous stage-gate processes can hurt the performance of novel new products (Sethi and Iqbal, 2008). NPDES seeks to foster a proper balance between process flexibility and discipline. The NPDES process allowed PaperPro to integrate core NPD practices in a logical fashion, including an emphasis on pre-development market planning, the application of industrial design, and a focus on cost engineering. The use of the market segmentation grid and competitive research allowed PaperPro to visualize its entire product strategy versus the competition, and direct future investment decisions therein. Industrial design pushed them to explore many design alternatives before selecting their top concept. Additionally, several of the design elements explored would be featured on future product variants. The use of cost modeling and analysis during the process helped guide decisions and material choices. Given the high percentage of costs determined during the early stages of design, it is imperative that firms track and base development decisions on these product and set-up costs. Evaluating production costs during development can provide the engineer with good design guidelines during the decision making process, particularly when these are linked to a set of production activities (Bras and Emblemsvag, 1995; Yamashina and Kubo, 2002). Unfortunately, the focus on cost actually delayed the 3000 project in the final stages prior to commercialization as a result of the redesigned, thinner and lower cost striker. In summation, this case illustrates that established firm NPD practices, if adopted intelligently and selectively, are wholly appropriate for development projects within new ventures. Over the course of the case, there were several important drivers other than the core NPD practices, which played a critical role in project outcomes. These include virtual team communication strategies, CAD efficiency, and physical prototype iteration. 4.1 Virtual team communication The 3000 development team was virtual, with limited in-person contact. Nearly all communication was performed via email and phone conversations, and the entire team never met in-person. From large companies to new ventures, development is increasingly virtual (Eppinger and Chitkara, 2006). Reich (1991) noted that, 'products are international composites. What is traded between nations is less often finished products than specialized problem solving (research, product design, fabrication), problem identifying (marketing, advertising, consulting), brokerage services, as well as routine components and services, all of which are combined to create value.' In today's global sourcing and manufacturing environment, NPD is highly dependent on e-collaboration tools for building on specialized knowledge across nations, organizations, and professions to develop customized products for different market segments (Marion et al., 2007). The 3000 took steps to facilitate communication between the virtual team, which is shown in Figure 20. These communication improvement steps included having the entire team on the same SolidWorks revision level. Additionally, all CAD files were transmitted daily to a virtual and external file-transfer-protocol (FTP) site for review by the team. Any changes to the CAD files would be reflected in the file name, and internal comments in SolidWorks. Although straightforward and common sense, disciplined application these simple steps helped increase communication efficiency. It is very easy for a distributed team to forget the importance of file management - the ramifications of which can be seen in costly launch delays such as the Airbus 380 (Wong, 2006). Lastly, communication with suppliers in China was done primarily through visual means. This included Skype (www.skype.com) voice over Internet protocol (VoIP) calls, with explicit pictures and comments. Additionally, all Chinese team members were fluent in English. In summation, in the current state of multinational virtual development teams, process and procedure goes a long way towards increasing development efficiencies. 4.2 CAD efficiency Another driving issue during development was CAD efficiency. As noted in Figure 19, CAD accounted for almost 75% of the project development cost. A 'faster,' more efficient designer (or external firm) could have a big impact on the speed at which a project is completed. In fact, during the 3000 project, a second designer was added to speed up development during the 3rd design revision. The time of revisions in front of the CAD terminal was the largest single resource expense on the project. Scaling existing models was difficult, and often after hours spent modifying existing models, new versions were created from scratch. This issue was discussed at length with PaperPro, and in their other projects, the expense of CAD was a similar percentage of project total. A topic for further study is the impact of CAD efficiency on total project cost and effectiveness among a wide variety of firms and industries - both small and large. The need for efficient CAD engineers is paramount, and needs to be addressed starting with engineering education. 4.3 Physical prototype iteration During development, some issues arose that were not directly related to the process, including long wait periods between prototypes made in China and testing in the U.S. As seen in Figure 18, these 'lulls' essentially halted the project. Although during this time other critical steps such as industrial design refinement and cost quoting occurred, the delays were non-trivial. Early in the project, U.S. prototypes were used for general form and limited function (rough fused deposition modeling (FDM) and SLA's, etc.), but as the design progressed the need for more production-like parts increased (e.g., machined, bronze housings to simulate cast zinc). These were all sourced in China and took several weeks to receive. During development, engineers would be better served investigating and planning the optimal resources for prototypes. However, these prototype iterations were essential in progressing the function of the unit towards desired specifications. Digital design tools such as FEA and EMS diagrams only served as a guide to design, real progress was made tweaking and testing physical prototype variations. In terms of the NPDES process itself, it was effective in developing a new product and an early-stage firm. The product was developed from concept to tooling kick-off in 14 months at a cost of approximately $125000. Although this is costlier than PaperPro's in-house projects, most of the cost can be tied directly to CAD model iterations. Considering that the stapler is expected to generate at least $500000 in revenue per year, the return on investment will be quick. The application of NPD practices to this early-stage development case highlights their potential and impact on project outcomes such as development duration, cost, and translation to commercialization. PaperPro management was pleased with the application of the process. The V.P. of Engineering noted: 'in our first development project, we did not use a formal process and at first I was skeptical we needed something more defined. The application of NPDES helped focus our long-term development strategy, and gave us some structure to navigate through difficulties in design and testing. Management reviews of progress were very beneficial, as project progress could be readily tied to the appropriate step and expenditure. As a company, we also never relied on engineering science to drive product design, it was always art by trial and error. The application of design tools has given us a quantitative basis - such as the spring force curve - for future models, perhaps even a 150-sheet model. Given the scope of the project, and risk of the 100 -sheet model, this process proved its merit.' The application of NPDES seems to have been positive, particularly given the relative complexity of the project and lack of direct stapler experience of the external development team. This highlights an important issue, namely, the efficacy of the method and how to validate it, as this is only a 'snap-shot' application to one firm, albeit on an actual consumer product that will soon reach market. Frey and Dym (2006) have noted that medical validation techniques may have a substantial impact on validating engineering design methods, which may be considered in future projects. Two options for validating NPDES as more data are obtained are careful collection and analysis of natural field data as the process is introduced and used by different firms, and well-defined 'clinical trials' when applicable. What is clear though is that NPD practices used during development and having clearly defined decision gates helped manage a complex and often frustrating new venture project. The NPDES process has the potential to do well in 'open water' development projects where a very simple structure can help guide the project as it moves along the development path. 5 Concluding remarks Very little research has investigated the process by which early-stage firms develop new products as such firms are often too busy trying to survive. The main drive for this paper was to apply NPD practices to an early-stage firm, and propose a tailored process for that function. Developed to give chaotic start-up companies a flexible structure to guide the development process, the NPDES process was successfully applied to the 3000 stapler at PaperPro. It gave the development team a structured guide to follow even when encountering unknown development problems and complexity. It also gave the firm's management team a focused forum to decide on further development and direction for the project. In addition, the focus on cost helped direct the development team, resulting in a product that surpassed its cost targets. What is uncertain is comparing the NPDES process to previous development efforts and gauging relative success. In future work, the NPDES process will be applied to a wide variety of early-stage firms, and data will be collected to validate its efficacy or lack thereof. The project described here was an initial effort, and it is clear that more work is needed to define metrics for its success (or failure)

Step by Step Solution

There are 3 Steps involved in it

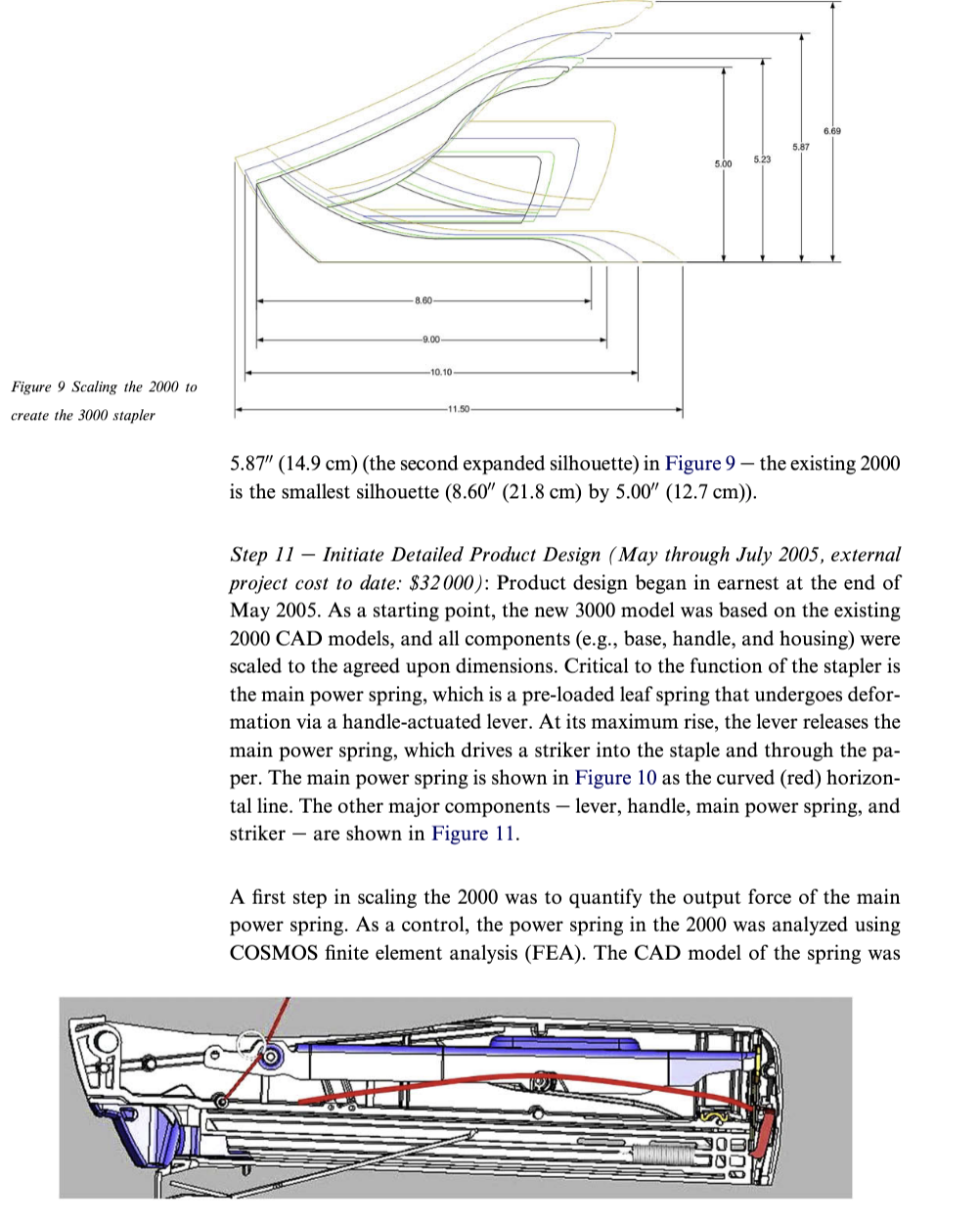

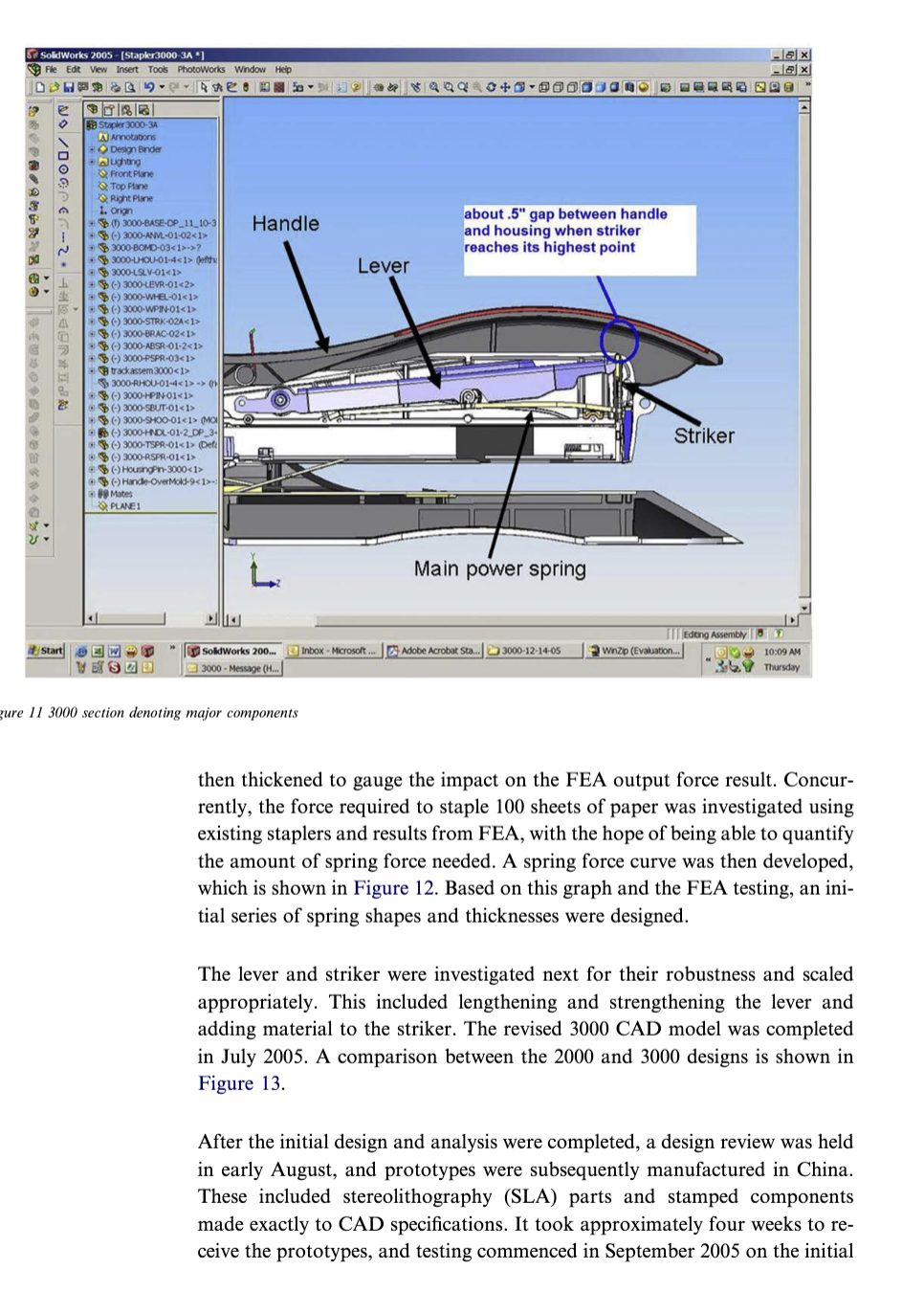

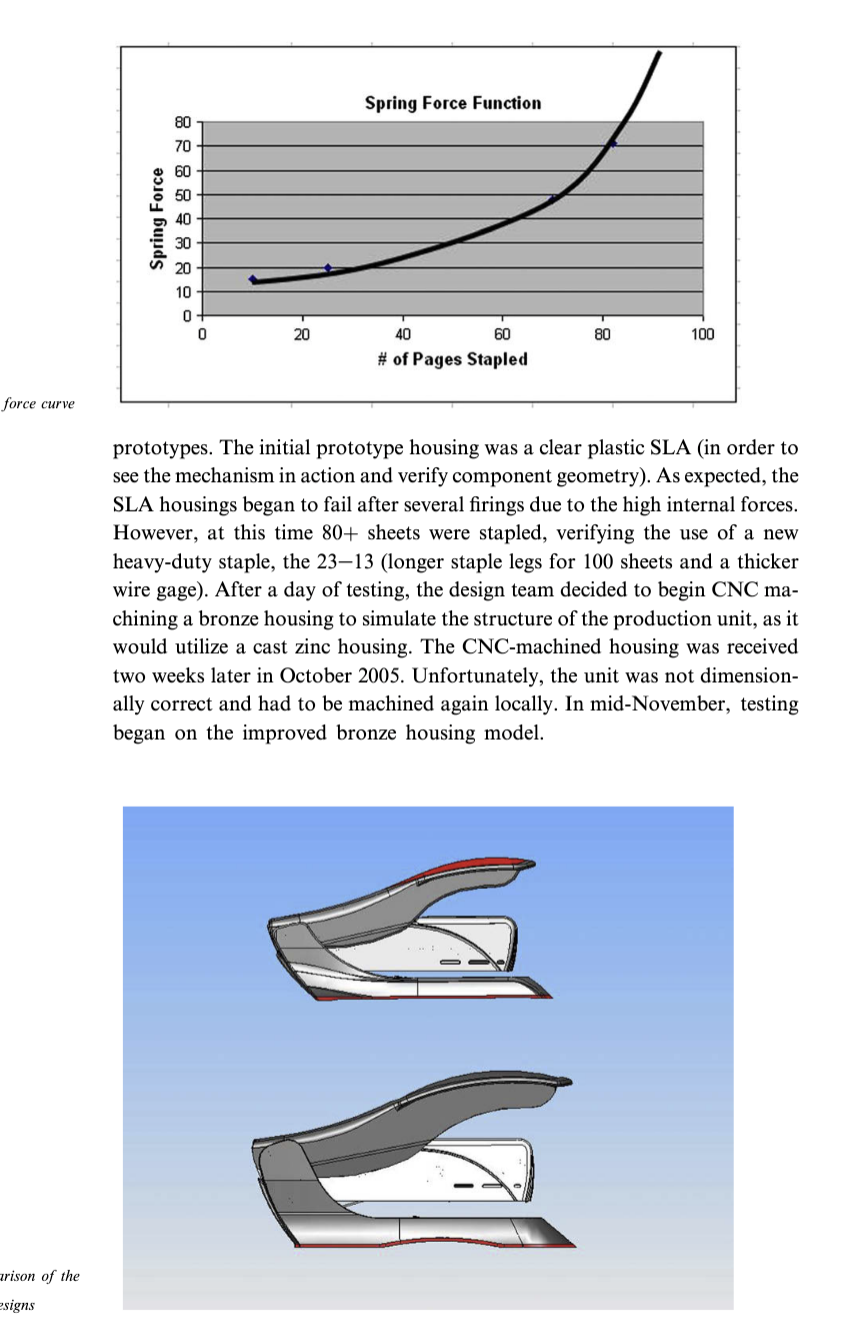

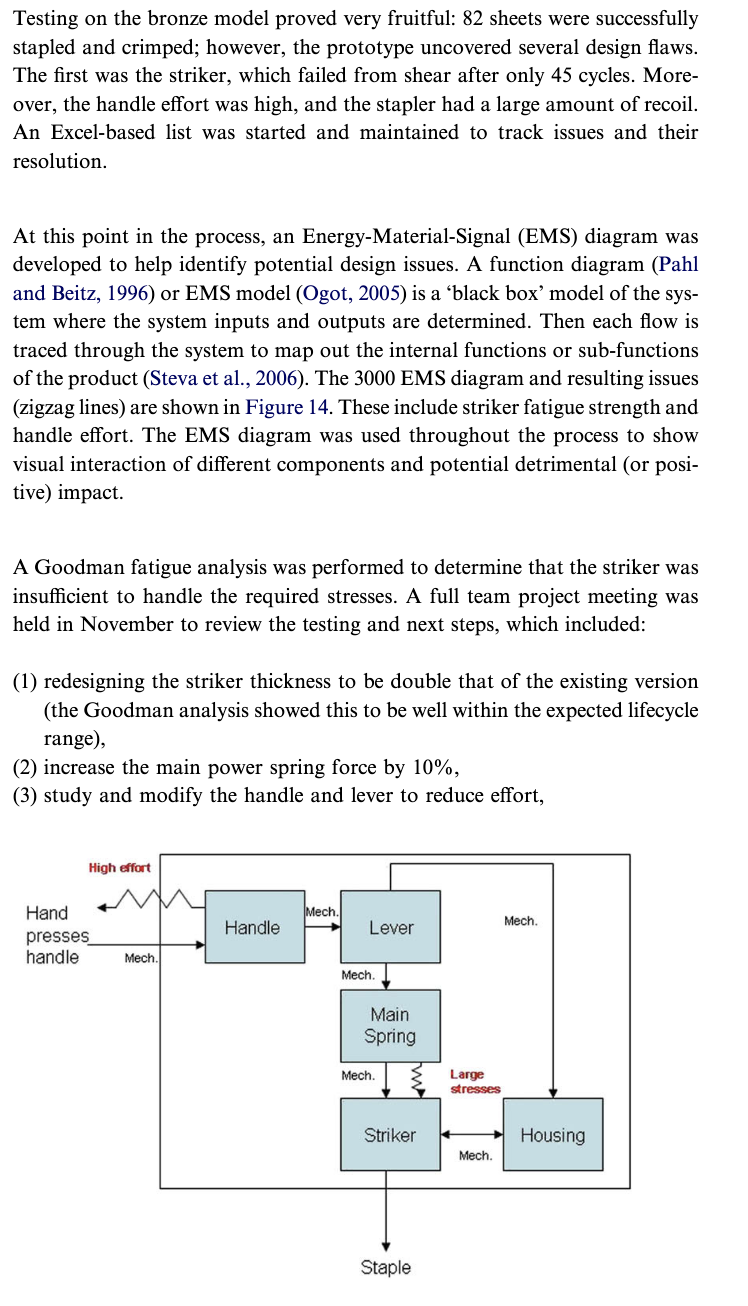

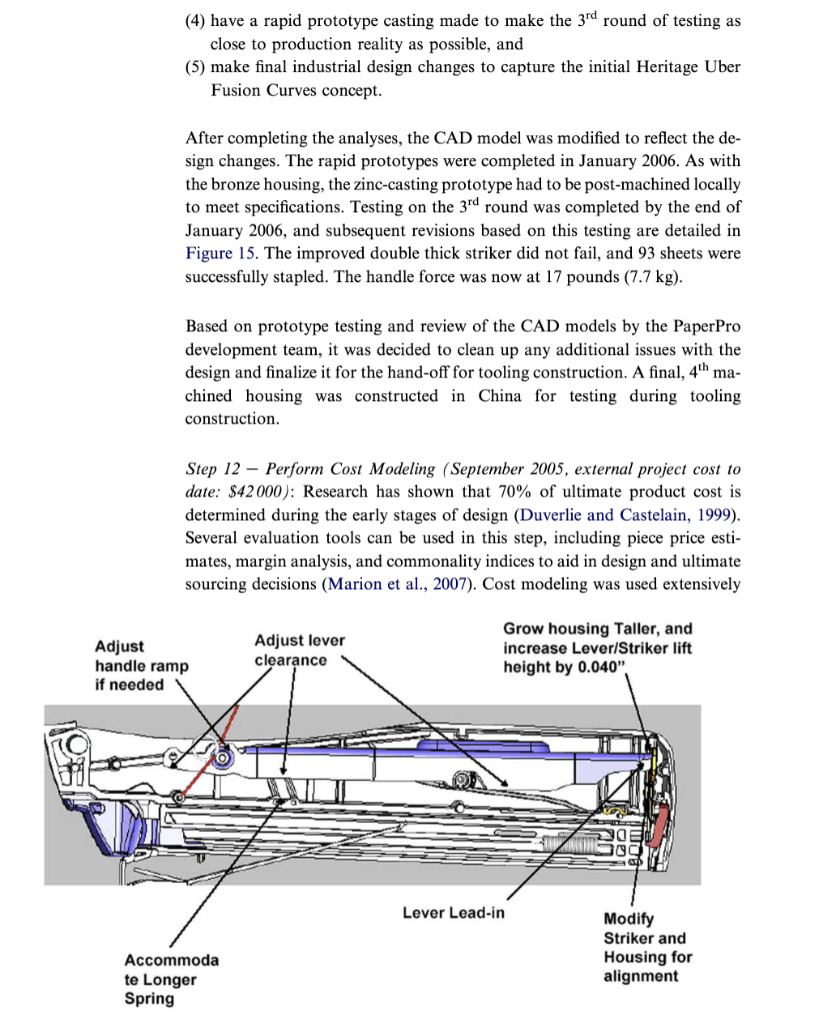

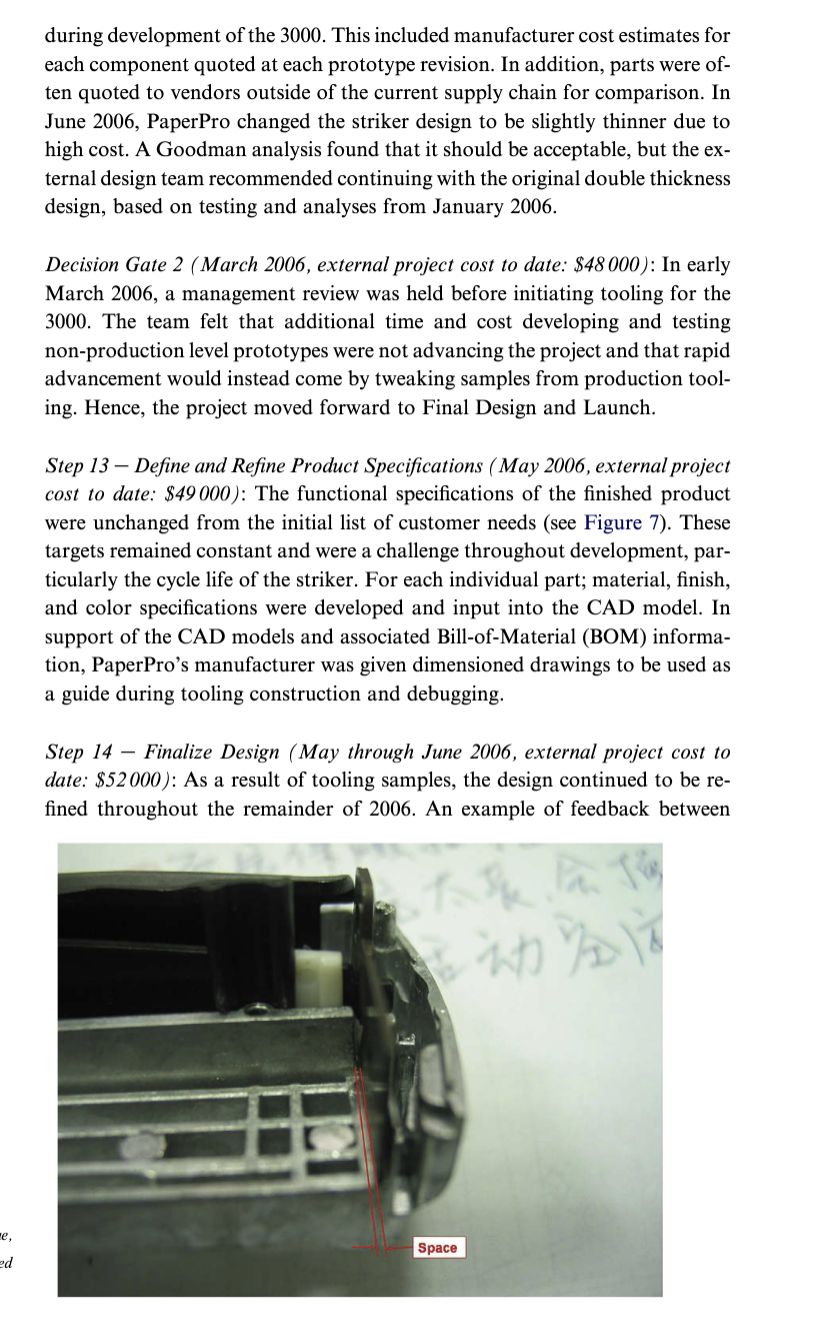

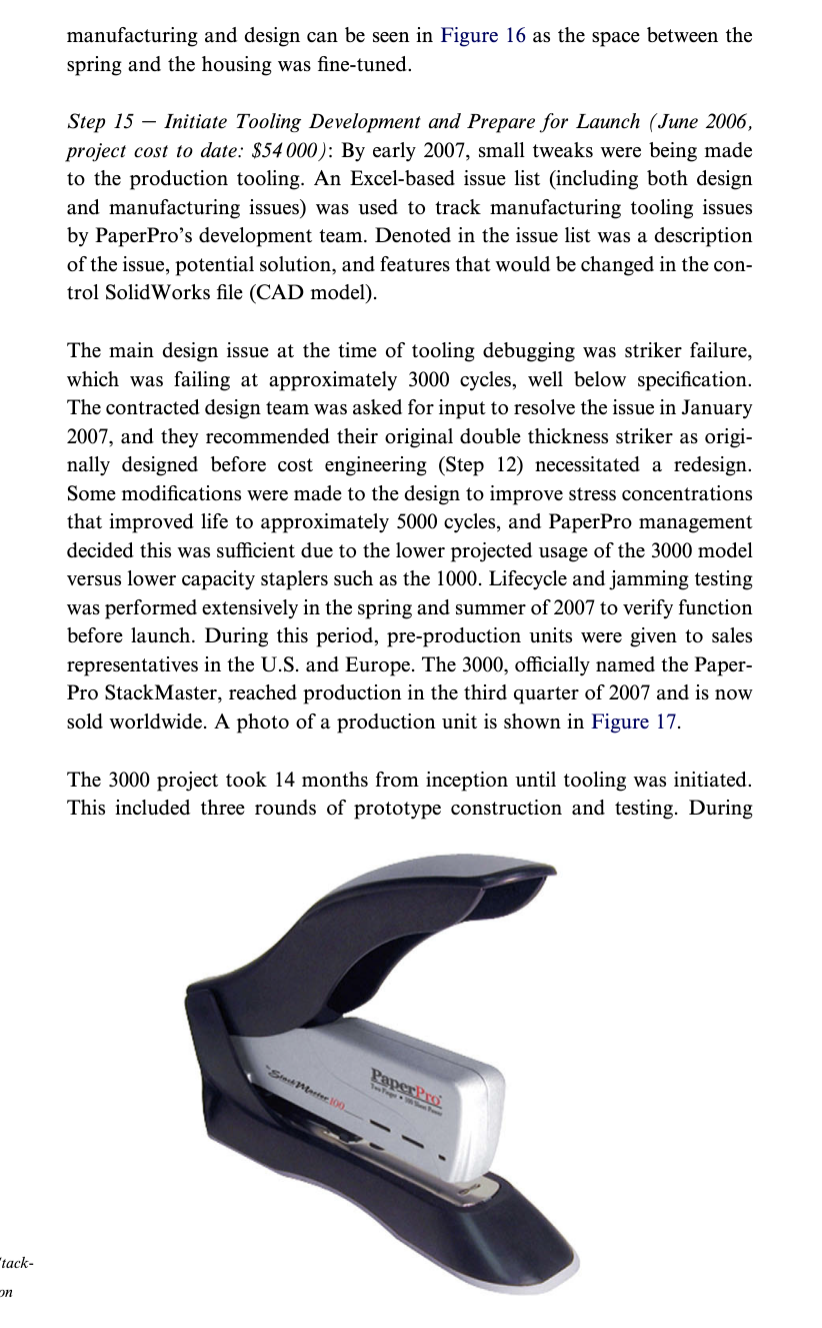

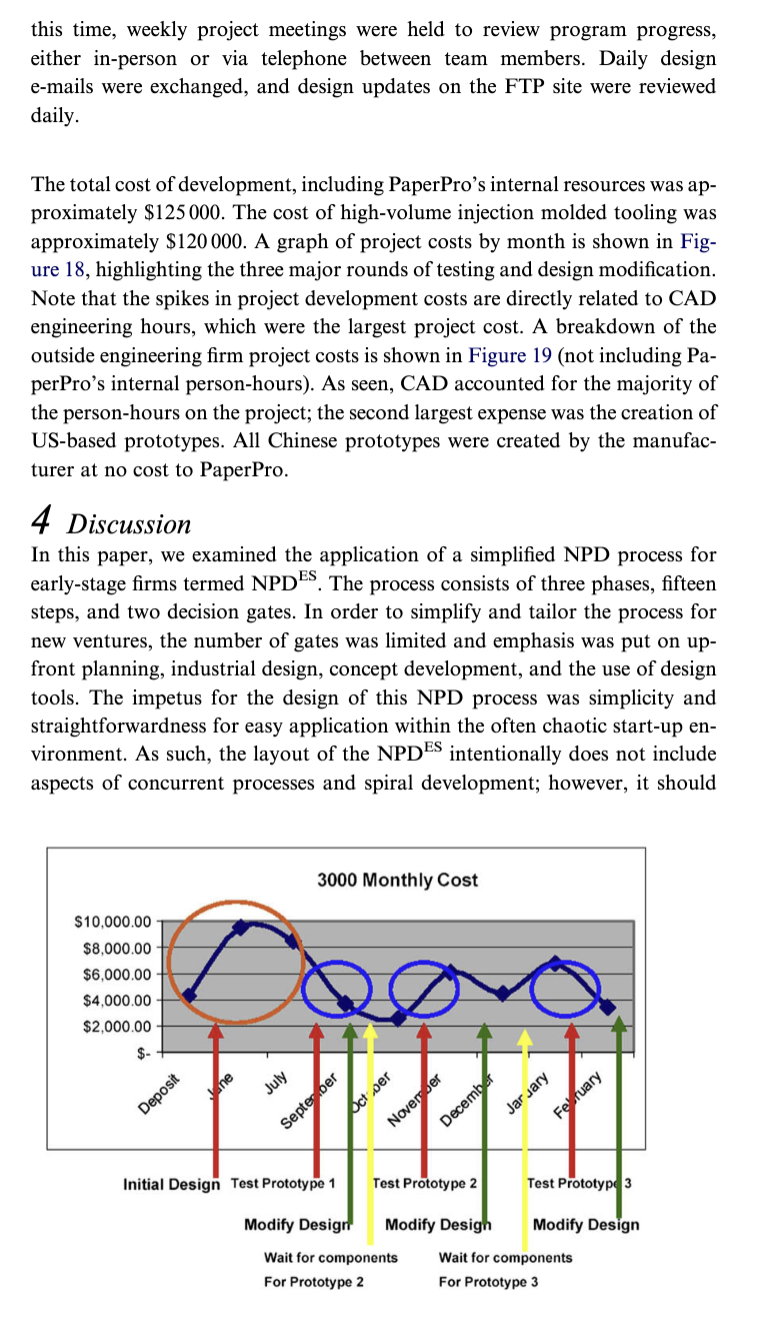

Get step-by-step solutions from verified subject matter experts