Answered step by step

Verified Expert Solution

Question

1 Approved Answer

Problems Note: PX means the problem may be solved with POM for Windows and/or Excel OM. Problems 1.1 to 1.17 relate to The Productivity

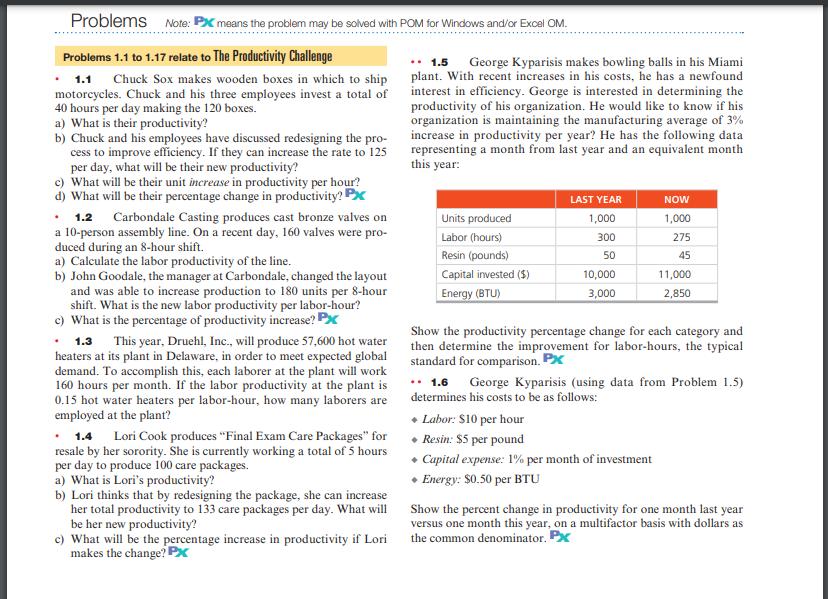

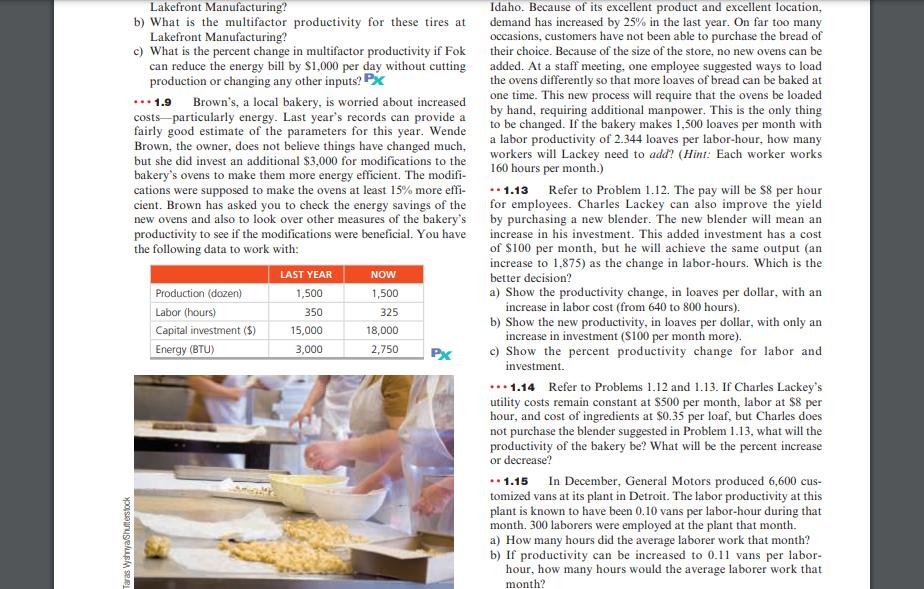

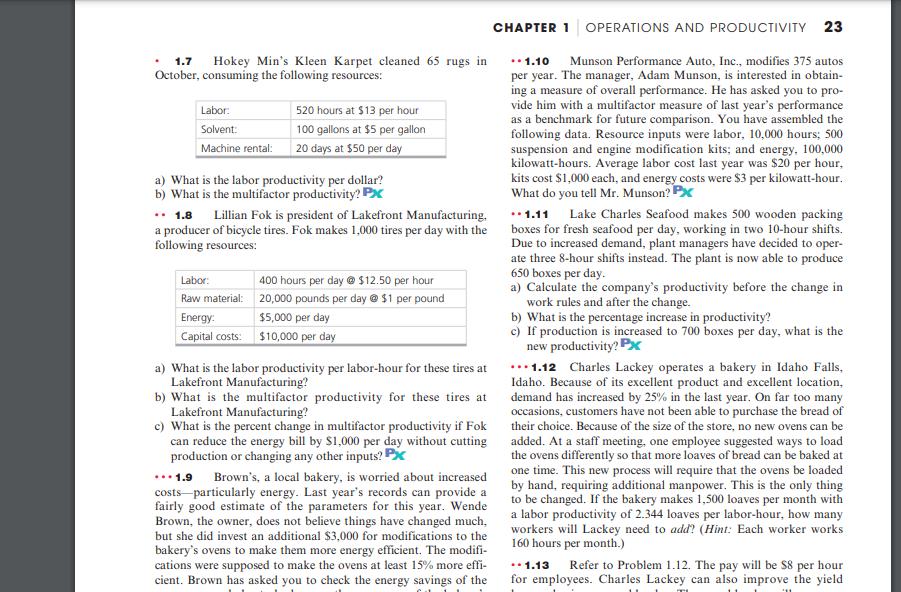

Problems Note: PX means the problem may be solved with POM for Windows and/or Excel OM. Problems 1.1 to 1.17 relate to The Productivity Challenge Chuck Sox makes wooden boxes in which to ship motorcycles. Chuck and his three employees invest a total of 40 hours per day making the 120 boxes. a) What is their productivity? b) Chuck and his employees have discussed redesigning the pro- cess to improve efficiency. If they can increase the rate to 125 per day, what will be their new productivity? c) What will be their unit increase in productivity per hour? d) What will be their percentage change in productivity? P 1.2 Carbondale Casting produces cast bronze valves on a 10-person assembly line. On a recent day, 160 valves were pro- duced during an 8-hour shift. a) Calculate the labor productivity of the line. b) John Goodale, the manager at Carbondale, changed the layout and was able to increase production to 180 units per 8-hour shift. What is the new labor productivity per labor-hour? c) What is the percentage of productivity increase? Px 1.3 This year, Druehl, Inc., will produce 57,600 hot water heaters at its plant in Delaware, in order to meet expected global demand. To accomplish this, each laborer at the plant will work 160 hours per month. If the labor productivity at the plant is 0.15 hot water heaters per labor-hour, how many laborers are employed at the plant? 1.4 Lori Cook produces "Final Exam Care Packages" for resale by her sorority. She is currently working a total of 5 hours per day to produce 100 care packages. a) What is Lori's productivity? b) Lori thinks that by redesigning the package, she can increase her total productivity to 133 care packages per day. What will be her new productivity? c) What will be the percentage increase in productivity if Lori makes the change? Px 1.5 George Kyparisis makes bowling balls in his Miami plant. With recent increases in his costs, he has a newfound interest in efficiency. George is interested in determining the productivity of his organization. He would like to know if his organization is maintaining the manufacturing average of 3% increase in productivity per year? He has the following data representing a month from last year and an equivalent month this year: Units produced Labor (hours) Resin (pounds) Capital invested ($) Energy (BTU) LAST YEAR 1,000 300 50 10,000 3,000 Labor: $10 per hour Resin: $5 per pound NOW 1,000 275 45 Show the productivity percentage change for each category and then determine the improvement for labor-hours, the typical standard for comparison. Px 11,000 2,850 .. 1.6 George Kyparisis (using data from Problem 1.5) determines his costs to be as follows: Capital expense: 1% per month of investment Energy: $0.50 per BTU Show the percent change in productivity for one month last year versus one month this year, on a multifactor basis with dollars as the common denominator. P Taras Vyshnya/Shutterstock Lakefront Manufacturing? b) What is the multifactor productivity for these tires at Lakefront Manufacturing? c) What is the percent change in multifactor productivity if Fok can reduce the energy bill by $1,000 per day without cutting production or changing any other inputs? Px ... 1.9 Brown's, a local bakery, is worried about increased costs particularly energy. Last year's records can provide a fairly good estimate of the parameters for this year. Wende Brown, the owner, does not believe things have changed much, but she did invest an additional $3,000 for modifications to the bakery's ovens to make them more energy efficient. The modifi- cations were supposed to make the ovens at least 15% more effi- cient. Brown has asked you to check the energy savings of the new ovens and also to look over other measures of the bakery's productivity to see if the modifications were beneficial. You have the following data to work with: Production (dozen) Labor (hours) Capital investment ($) Energy (BTU) LAST YEAR 1,500 350 15,000 3,000 NOW 1,500 325 18,000 2,750 Px Idaho. Because of its excellent product and excellent location, demand has increased by 25% in the last year. On far too many occasions, customers have not been able to purchase the bread of their choice. Because of the size of the store, no new ovens can be added. At a staff meeting, one employee suggested ways to load the ovens differently so that more loaves of bread can be baked at one time. This new process will require that the ovens be loaded by hand, requiring additional manpower. This is the only thing to be changed. If the bakery makes 1,500 loaves per month with a labor productivity of 2.344 loaves per labor-hour, how many workers will Lackey need to add? (Hint: Each worker works 160 hours per month.) ..1.13 Refer to Problem 1.12. The pay will be $8 per hour for employees. Charles Lackey can also improve the yield by purchasing a new blender. The new blender will mean an increase in his investment. This added investment has a cost of $100 per month, but he will achieve the same output (an increase to 1,875) as the change in labor-hours. Which is the better decision? a) Show the productivity change, in loaves per dollar, with an increase in labor cost (from 640 to 800 hours). b) Show the new productivity, in loaves per dollar, with only an increase in investment ($100 per month more). c) Show the percent productivity change for labor and investment. ...1.14 Refer to Problems 1.12 and 1.13. If Charles Lackey's utility costs remain constant at $500 per month, labor at $8 per hour, and cost of ingredients at $0.35 per loaf, but Charles does not purchase the blender suggested in Problem 1.13, what will the productivity of the bakery be? What will be the percent increase or decrease? ..1.15 In December, General Motors produced 6,600 cus- tomized vans at its plant in Detroit. The labor productivity at this plant is known to have been 0.10 vans per labor-hour during that month. 300 laborers were employed at the plant that month. a) How many hours did the average laborer work that month? b) If productivity can be increased to 0.11 vans per labor- hour, how many hours would the average laborer work that month? 1.7 Hokey Min's Kleen Karpet cleaned 65 rugs in October, consuming the following resources: Labor: Solvent: Machine rental: 520 hours at $13 per hour 100 gallons at $5 per gallon 20 days at $50 per day a) What is the labor productivity per dollar? b) What is the multifactor productivity? P 1.8 Lillian Fok is president of Lakefront Manufacturing. a producer of bicycle tires. Fok makes 1,000 tires per day with the following resources: Labor: Raw material: Energy: Capital costs: 400 hours per day @ $12.50 per hour 20,000 pounds per day @ $1 per pound $5,000 per day $10,000 per day a) What is the labor productivity per labor-hour for these tires at Lakefront Manufacturing? b) What is the multifactor productivity for these tires at Lakefront Manufacturing? c) What is the percent change in multifactor productivity if Fok can reduce the energy bill by $1,000 per day without cutting production or changing any other inputs? Px ... 1.9 Brown's, a local bakery, is worried about increased costs particularly energy. Last year's records can provide a fairly good estimate of the parameters for this year. Wende Brown, the owner, does not believe things have changed much. but she did invest an additional $3,000 for modifications to the bakery's ovens to make them more energy efficient. The modifi- cations were supposed to make the ovens at least 15% more effi- cient. Brown has asked you to check the energy savings of the CHAPTER 1 OPERATIONS AND PRODUCTIVITY 23 ..1.10 Munson Performance Auto, Inc., modifies 375 autos per year. The manager, Adam Munson, is interested in obtain- ing a measure of overall performance. He has asked you to pro- vide him with a multifactor measure of last year's performance as a benchmark for future comparison. You have assembled the following data. Resource inputs were labor, 10,000 hours; 500 suspension and engine modification kits; and energy, 100,000 kilowatt-hours. Average labor cost last year was $20 per hour, kits cost $1,000 each, and energy costs were $3 per kilowatt-hour. What do you tell Mr. Munson? P **1.11 Lake Charles Seafood makes 500 wooden packing boxes for fresh seafood per day, working in two 10-hour shifts. Due to increased demand, plant managers have decided to oper- ate three 8-hour shifts instead. The plant is now able to produce 650 boxes per day. a) Calculate the company's productivity before the change in work rules and after the change. b) What is the percentage increase in productivity? c) If production is increased to 700 boxes per day, what is the new productivity? Px ... 1.12 Charles Lackey operates a bakery in Idaho Falls, Idaho. Because of its excellent product and excellent location, demand has increased by 25% in the last year. On far too many occasions, customers have not been able to purchase the bread of their choice. Because of the size of the store, no new ovens can be added. At a staff meeting, one employee suggested ways to load the ovens differently so that more loaves of bread can be baked at one time. This new process will require that the ovens be loaded by hand, requiring additional manpower. This is the only thing to be changed. If the bakery makes 1,500 loaves per month with a labor productivity of 2.344 loaves per labor-hour, how many workers will Lackey need to add? (Hint: Each worker works 160 hours per month.) ..1.13 Refer to Problem 1.12. The pay will be $8 per hour for employees. Charles Lackey can also improve the yield 24 PART 1 INTRODUCTION TO OPERATIONS MANAGEMENT ..1.16 Susan Williams runs a small Flagstaff job shop where garments are made. The job shop employs eight workers. Each worker is paid $10 per hour. During the first week of March, each worker worked 45 hours. Together, they produced a batch of 132 garments. Of these garments, 52 were "seconds" (meaning that they were flawed). The seconds were sold for $90 each at a factory outlet store. The remaining 80 garments were sold to retail outlets at a price of $198 per garment. What was the labor productivity, in dollars per labor-hour, at this job shop during the first week of March? tomized vans at its plant in Detroit. The labor productivity at this plant is known to have been 0.10 vans per labor-hour during that month. 300 laborers were employed at the plant that month. a) How many hours did the average laborer work that month? b) If productivity can be increased to 0.11 vans per labor- hour, how many hours would the average laborer work that month? ... 1.17 As part of a study for the Department of Labor Statistics, you are assigned the task of evaluating the improve- ment in productivity of small businesses. Data for one of the small businesses you are to evaluate are shown at right. The data are the monthly average of last year and the monthly average this year. Determine the multifactor productivity with dollars as the common denominator for: a) Last year. b) This year. c) Then determine the percent change in productivity for the monthly average last year versus the monthly average this year on a multifactor basis. Labor: $8 per hour . Capital: 0.83% per month of investment Energy: $0.60 per BTU Production (dozen) Labor (hours) Capital investment ($) Energy (BTU) LAST YEAR 1,500 350 15,000 3,000 THIS YEAR 1,500 325 18,000 2,700

Step by Step Solution

★★★★★

3.45 Rating (158 Votes )

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started