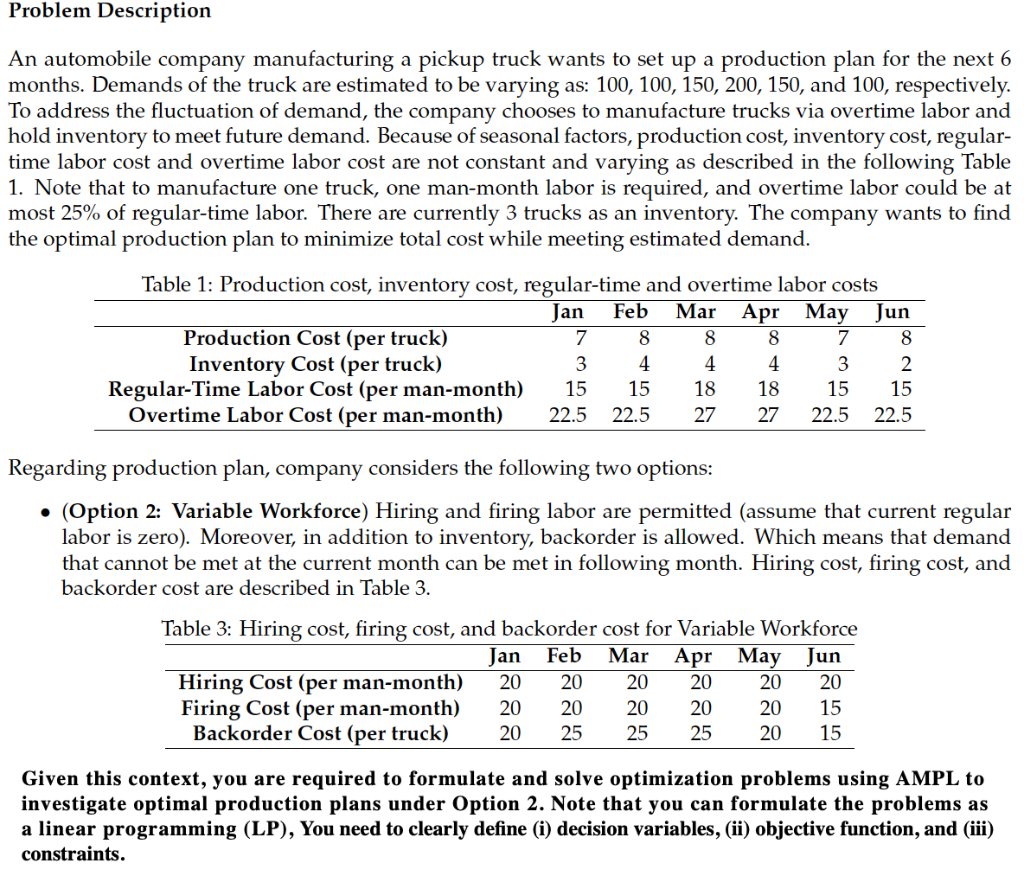

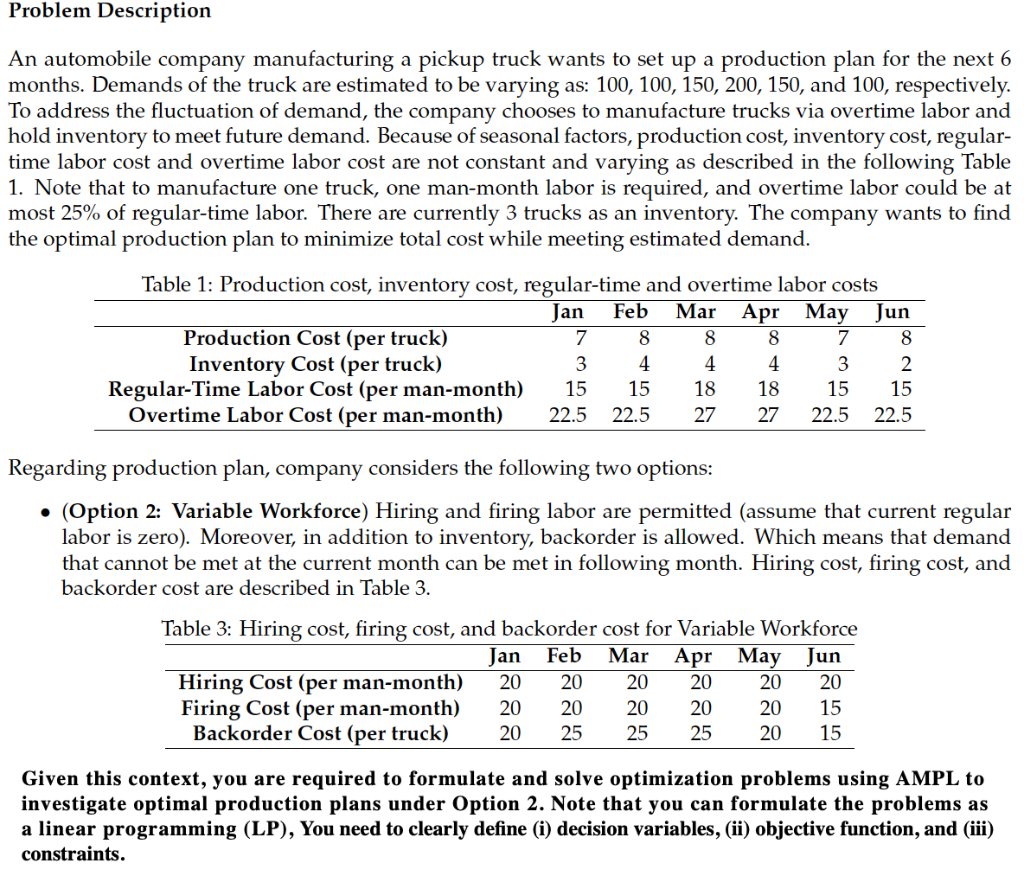

Problem Description An automobile company manufacturing a pickup truck wants to set up a production plan for the next 6 months. Demands of the truck are estimated to be varying as: 100, 100, 150, 200, 150, and 100, respectively. To address the fluctuation of demand, the company chooses to manufacture trucks via overtime labor and hold inventory to meet future demand. Because of seasonal factors, production cost, inventory cost, regular- time labor cost and overtime labor cost are not constant and varying as described in the following Table 1. Note that to manufacture one truck, one man-month labor is required, and overtime labor could be at most 25% of regular-time labor. There are currently 3 trucks as an inventory. The company wants to find the optimal production plan to minimize total cost while meeting estimated demand. Table 1: Production cost, inventory cost, regular-time and overtime labor costs Jan Feb Mar Apr May Jun Production Cost (per truck) 7 8 8 8 7 8 Inventory Cost (per truck) 3 4 4 4 3 2 Regular-Time Labor Cost (per man-month) 15 15 18 18 15 15 Overtime Labor Cost (per man-month) 22.5 22.5 27 27 22.5 22.5 Regarding production plan, company considers the following two options: (Option 2: Variable Workforce) Hiring and firing labor are permitted (assume that current regular labor is zero). Moreover, in addition to inventory, backorder is allowed. Which means that demand that cannot be met at the current month can be met in following month. Hiring cost, firing cost, and backorder cost are described in Table 3. Table 3: Hiring cost, firing cost, and backorder cost for Variable Workforce Jan Feb Mar Apr May Jun Hiring Cost (per man-month) 20 20 20 20 20 20 Firing Cost (per man-month) 20 20 20 20 20 15 Backorder Cost (per truck) 20 25 25 25 20 15 Given this context, you are required to formulate and solve optimization problems using AMPL to investigate optimal production plans under Option 2. Note that you can formulate the problems as a linear programming (LP), You need to clearly define (i) decision variables, (ii) objective function, and (iii) constraints. Problem Description An automobile company manufacturing a pickup truck wants to set up a production plan for the next 6 months. Demands of the truck are estimated to be varying as: 100, 100, 150, 200, 150, and 100, respectively. To address the fluctuation of demand, the company chooses to manufacture trucks via overtime labor and hold inventory to meet future demand. Because of seasonal factors, production cost, inventory cost, regular- time labor cost and overtime labor cost are not constant and varying as described in the following Table 1. Note that to manufacture one truck, one man-month labor is required, and overtime labor could be at most 25% of regular-time labor. There are currently 3 trucks as an inventory. The company wants to find the optimal production plan to minimize total cost while meeting estimated demand. Table 1: Production cost, inventory cost, regular-time and overtime labor costs Jan Feb Mar Apr May Jun Production Cost (per truck) 7 8 8 8 7 8 Inventory Cost (per truck) 3 4 4 4 3 2 Regular-Time Labor Cost (per man-month) 15 15 18 18 15 15 Overtime Labor Cost (per man-month) 22.5 22.5 27 27 22.5 22.5 Regarding production plan, company considers the following two options: (Option 2: Variable Workforce) Hiring and firing labor are permitted (assume that current regular labor is zero). Moreover, in addition to inventory, backorder is allowed. Which means that demand that cannot be met at the current month can be met in following month. Hiring cost, firing cost, and backorder cost are described in Table 3. Table 3: Hiring cost, firing cost, and backorder cost for Variable Workforce Jan Feb Mar Apr May Jun Hiring Cost (per man-month) 20 20 20 20 20 20 Firing Cost (per man-month) 20 20 20 20 20 15 Backorder Cost (per truck) 20 25 25 25 20 15 Given this context, you are required to formulate and solve optimization problems using AMPL to investigate optimal production plans under Option 2. Note that you can formulate the problems as a linear programming (LP), You need to clearly define (i) decision variables, (ii) objective function, and (iii) constraints