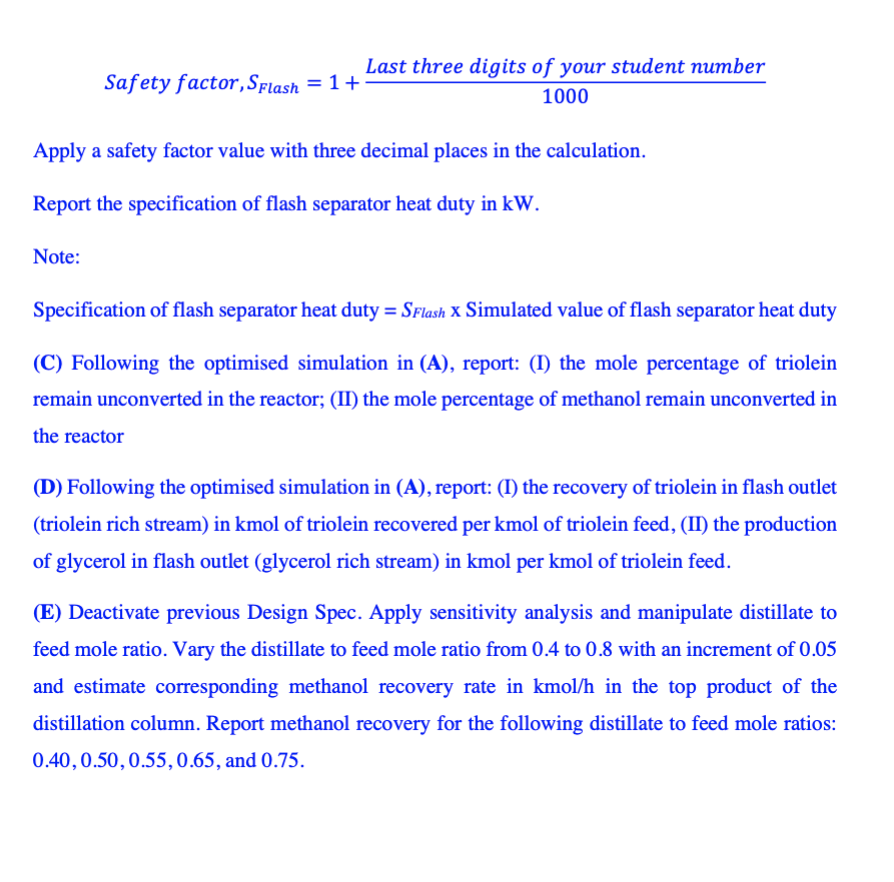

Production and purification of glycerol and methyl oleate Glycerol is a non-toxic, biodegradable, colourless, and viscous liquid. It is commonly used as food preservative, sweetener demulcent and anti-inflammatory agent. Glycerol (C3H8O3) is produced along with methyl oleate (C19H36O2) in a biodiesel plant via transesterification reaction between triolein (C57H104O6) and methanol (CH3OH) as follows: C57H104O6+3CH3OH3C19H36O2+C3H8O3 The transesterification reaction described above occurs in a vigorously stirred reactor. Pure triolein and pure methanol feed at ambient conditions with a flow rate of 16kmol/h and 280 kmol/h, respectively enter the reactor. The reaction occurs at 58C and 1 atm in liquid phase and produces methyl oleate and glycerol. The residence time for this reaction is 60 seconds. Consider UNIFAC as the property method for this problem. The reaction is second order overall. Both forward and reverse reactions are first-order reactions with respect to each of the reactants and the concentration basis for kinetic parameters is molarity. The activation energy and pre-exponential factor for the forward reaction are 3.15 kJ/kmol and 0.17m3/kmols, respectively. For the reverse reaction, the values of activation energy and pre-exponential factor are 2.69kJ/kmol and 0.45m3/kmol.s, respectively. The product from the reactor enters to a distillation column. The distillation column has 20 stages and a reflux ratio of 10 . The feed stage and distillate to feed mole ratio are 10 and 0.8 , respectively. The condenser and reboiler have an equal pressure of 1.2 atm and the condenser is operating at a 'total' condenser mode. Consider a shortcut distillation column in the simulation. The bottom product from the distillation column enters to a flash separator consisting of a vapour outlet and two liquid outlet streams. The flash separator is operated at 175C and 101.02 kPa. Tasks: (A) Apply Design Spec to find the optimum temperature of flash separator to achieve 99mol% \pm 0.01 of methanol in the vapour phase of flash separator. (B) Following the optimised simulation in (A), you are asked to provide specification of flash separator heat duty including a safety factor to a supplier. Safety factor,SFlash=1+1000Lastthreedigitsofyourstudentnumber Apply a safety factor value with three decimal places in the calculation. Report the specification of flash separator heat duty in kW. Note: Specification of flash separator heat duty =SFlashx Simulated value of flash separator heat duty (C) Following the optimised simulation in (A), report: (I) the mole percentage of triolein remain unconverted in the reactor; (II) the mole percentage of methanol remain unconverted in the reactor (D) Following the optimised simulation in (A), report: (I) the recovery of triolein in flash outlet (triolein rich stream) in kmol of triolein recovered per kmol of triolein feed, (II) the production of glycerol in flash outlet (glycerol rich stream) in kmol per kmol of triolein feed. (E) Deactivate previous Design Spec. Apply sensitivity analysis and manipulate distillate to feed mole ratio. Vary the distillate to feed mole ratio from 0.4 to 0.8 with an increment of 0.05 and estimate corresponding methanol recovery rate in kmol/h in the top product of the distillation column. Report methanol recovery for the following distillate to feed mole ratios: 0.40,0.50,0.55,0.65, and 0.75