Answered step by step

Verified Expert Solution

Question

1 Approved Answer

QUESTION 1 (30 points) L0-4: apply Calculation of Cost of Capital, Capital Budgeting Cash Flow and Techniques for Decision Making One of the most affected

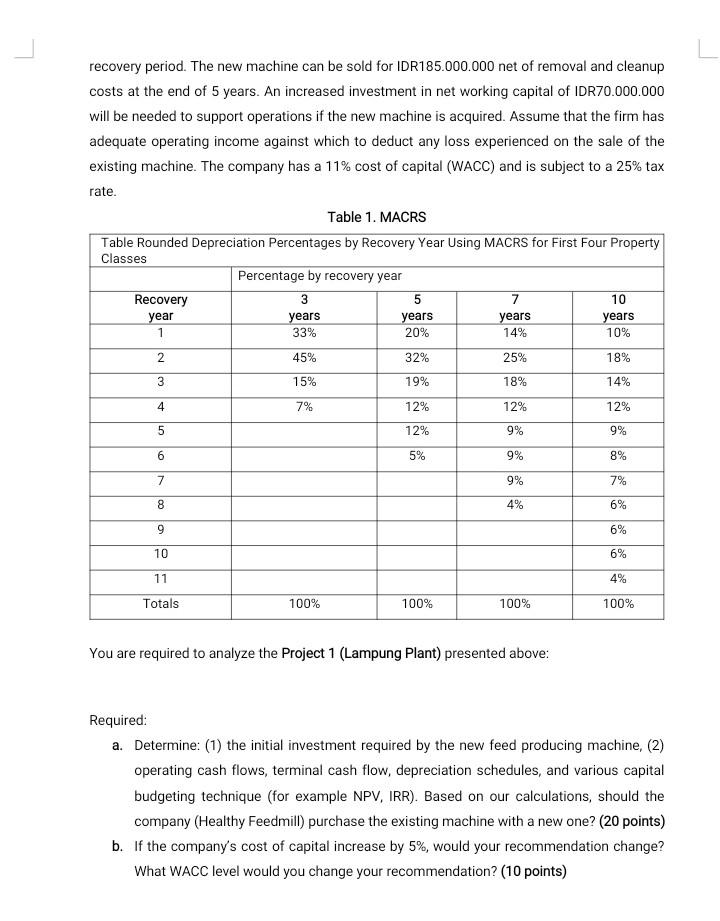

QUESTION 1 (30 points) L0-4: apply Calculation of Cost of Capital, Capital Budgeting Cash Flow and Techniques for Decision Making One of the most affected industries due to the COVID-19 pandemic is the poultry industry. High costs and sluggish demand has terribly affected sales of many feed mills in Indonesia. Healthy Feedmill, an integrated poultry feed manufacturing company, established in 2001. The company has numerous business lines and subsidiaries throughout Indonesia. The biggest business activity is the poultry feed and poultry and meat products. During these past few years, Healthy Feedmill maintains a relatively stable market share of 5% in Indonesia market while being the third largest feed mill company. However, a massive decline in purchasing power and strict social distance restrictions during 2020 have influenced sales and business segment performance of the company. Company's management is quite positive on the economic Outlook and satisfactory sales performance in 2021 onward. The company has prepared strategies for 2021-2022 including corporate restructuring and capital asset management projects. The strategic developments are including projects for the company's 2 (two) factories in Lampung and Semarang. Since the factories in Lampung and Semarang have been in existence for 10 years, many production facilities including machinery have been damaged or are no longer able to support the company's operational activities. The company plans to replace 2 (two) existing feed processing machines with new machines from India. The new machines are expected to help the company's higher productivity ratio and cost efficiencies. Project 1: Lampung Plant Healthy Feedmill is considering the purchase of a new feed processing machines for the Lampung plant. The new machine costs IDR450.000.000 and requires installation costs of Page 1 of IDR50.000.000. The existing/old machine can be sold currently for IDR75.000.000 before taxes. The existing feed machine is 2 years old, cost IDR 260.000.000 new, and has a IDR130.000.000 book value and a remaining useful life of 5 years. The machine was being depreciated under MACRS (table provided below), using a 5-year recovery period. Thus, it has the final 4 years of depreciation remaining. If it is held for 5 more years, the machine's market value at the end of year 5 will be $0. Over its 5-year usage life, the new feed producer machine would reduce the plant's operating costs by IDR150.000.000 per year. The new machine will be depreciated under MACRS, using a 5-year recovery period. The new machine can be sold for IDR170.000.000 net of removal and cleanup costs at the end of 5 years. An increased investment in net working capital of IDR50.000.000 will be needed to support operations if the new machine is acquired. Assume that the firm has adequate operating income against which to deduct any loss experienced on the sale of the existing machine. The company has a 10% cost of capital (WACC) and is subject to a 25% tax rate. Project 2: Semarang Plant Healthy Feedmill's management also considers to invest in a new feed processing machines for the Semarang plant, thanks to the growing poultry feed and processed meat products demand from central and east Java area. Semarang plant currently operates at higher production level compare to that of the Lampung plant. Considering Lampung plant productivity ratio, the new machine should have bigger capacity than the one considered for Lampung plant operation. The new machine costs IDR550.000.000 and requires installation costs of IDR100.000.000. The existing/old machine can be sold currently for IDR80.000.000 before taxes. The existing feed processing machine is 2 years old, cost IDR280.000.000 new, and has a IDR150.000.000 book value and a remaining useful life of 5 years. The machine was being depreciated under MACRS (table provided), using a 5-year recovery period. Thus, it has the final 4 years of depreciation remaining. If it is held for 5 more years, the machine's market value at the end of year 5 will be $0. Over its 5-year the new duce the plant's operating costs by IDR175.000.000 per year. The new machine will be depreciated under MACRS, using a 5-year Page 2 of recovery period. The new machine can be sold for IDR185.000.000 net of removal and cleanup costs at the end of 5 years. An increased investment in net working capital of IDR70.000.000 will be needed to support operations if the new machine is acquired. Assume that the firm has adequate operating income against which to deduct any loss experienced on the sale of the existing machine. The company has a 11% cost of capital (WACC) and is subject to a 25% tax rate. Table 1. MACRS Table Rounded Depreciation Percentages by Recovery Year Using MACRS for First Four Property Classes Percentage by recovery year Recovery 3 5 year years years years years 33% 20% 10% 7 10 1 14% 2 45% 32% 25% 18% 3 15% 19% 18% 14% 4 7% 12% 12% 12% 12% 9% 9% + LOON 5% 9% 8% 9% 7% 8 4% 6% 9 6% 10 6% 11 4% Totals 100% 100% 100% 100% You are required to analyze the Project 1 (Lampung Plant) presented above: Required: a. Determine: (1) the initial investment required by the new feed producing machine, (2) operating cash flows, terminal cash flow, depreciation schedules, and various capital budgeting technique (for example NPV, IRR). Based on our calculations, should the company (Healthy Feedmill) purchase the existing machine with a new one? (20 points) b. If the company's cost of capital increase by 5%, would your recommendation change? What WACC level would you change your recommendation? (10 points)

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started